BRP-Rotax

MAINTENANCE MANUAL

NNOOTTEE

Due to limited tolerances, it may be difficult to push the drive gear onto the end of

the crankshaft. If necessary, push it on in another position.

Step

Procedure

2 Secure the Hex. nut M30x1,5 with LOCTITE 648 and screw it onto the

crankshaft along with the friction washer VS-30. Tightening torque 300

Nm (221 ft.lb.).

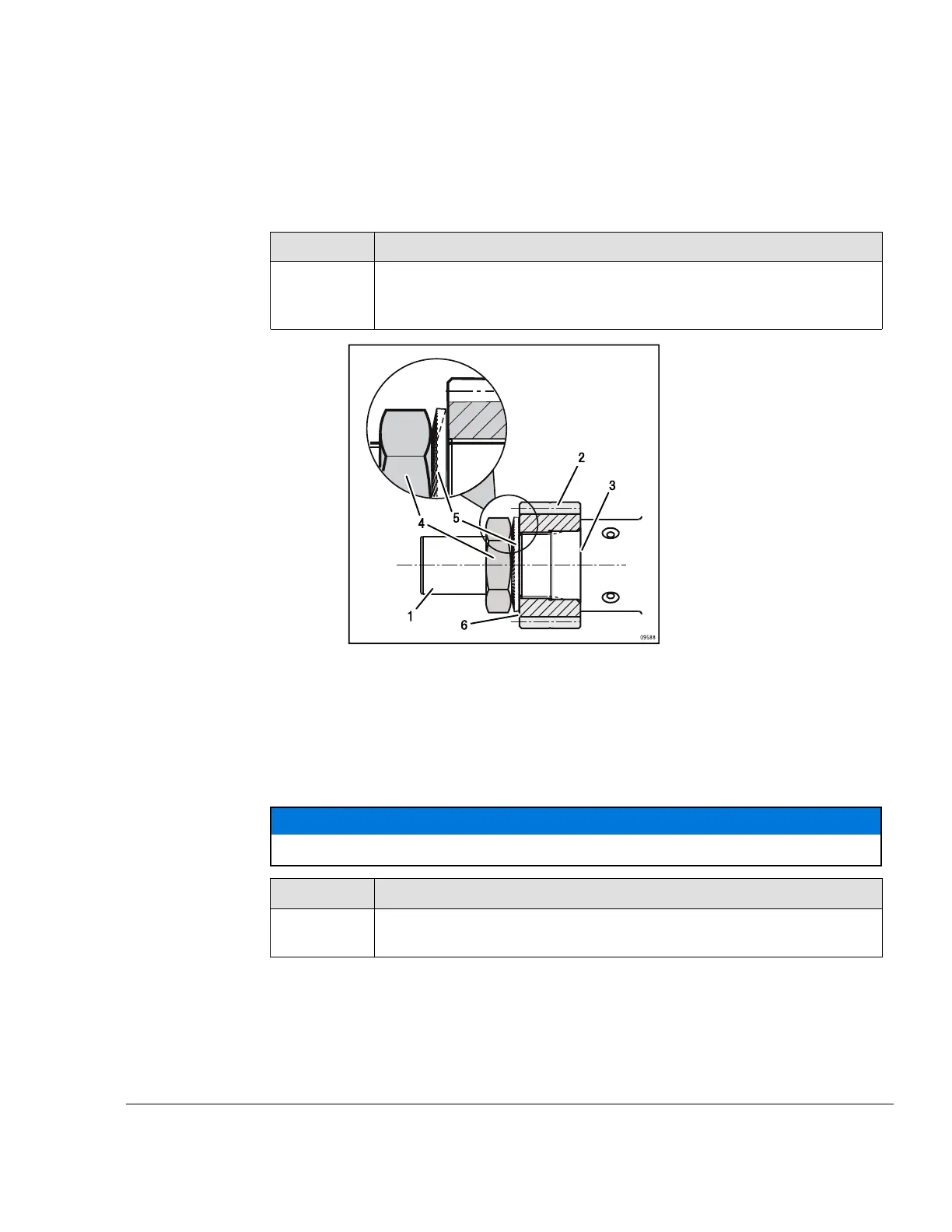

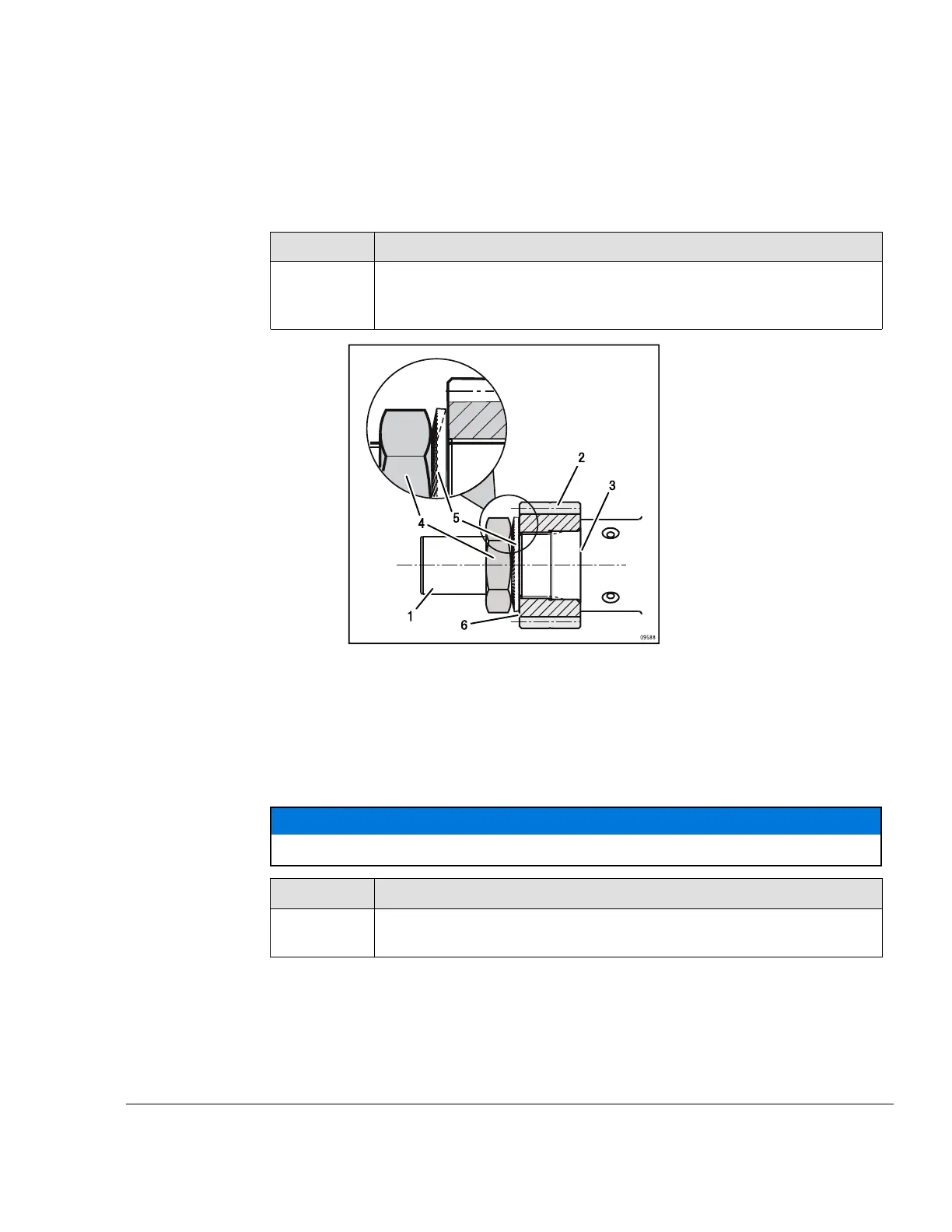

Figure 5.7

1

Crankshaft (power take off side)

2

Drive gear

3 Crankshaft 4 Hex. nut

5 VS-30 friction washer 6 Serial number

ATTENTION

The sealing surface must be free from dirt and oil.

Step

Procedure

3

Inspect the run-out. See also Chapter 72-10-00 section Wear limits.

(CS24)

NNOOTTEE

If there is slight vertical run-out, replace the nut and repeat the measurement.

Effectivity: 915 i A Series

Edition 0/Rev. 0

05–50–00

Page 9

December 01 2017

Loading...

Loading...