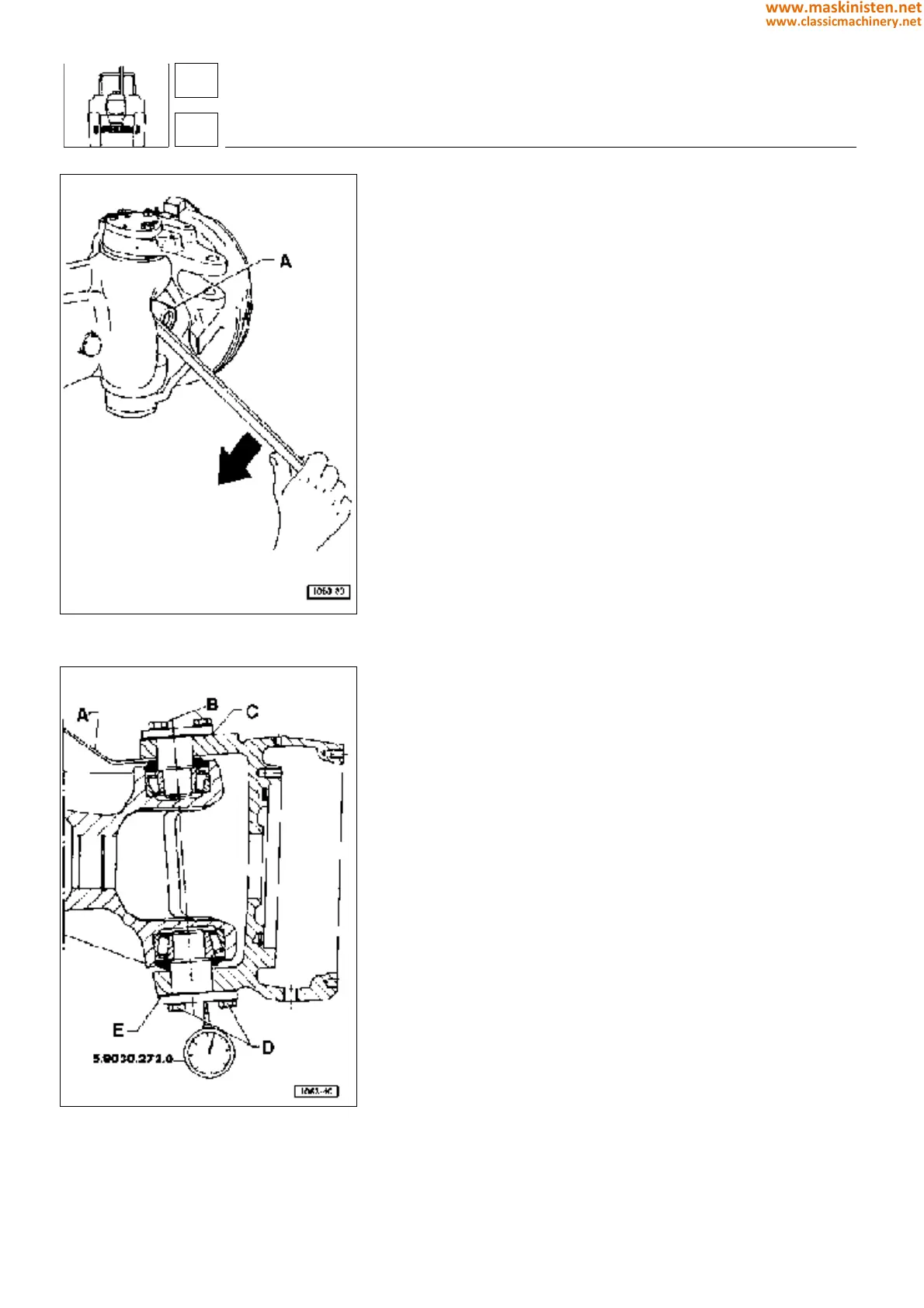

Fig. 12 - Prising with a lever to hold the axle

shaft in position when mounting the final epicy-

clic reducer.

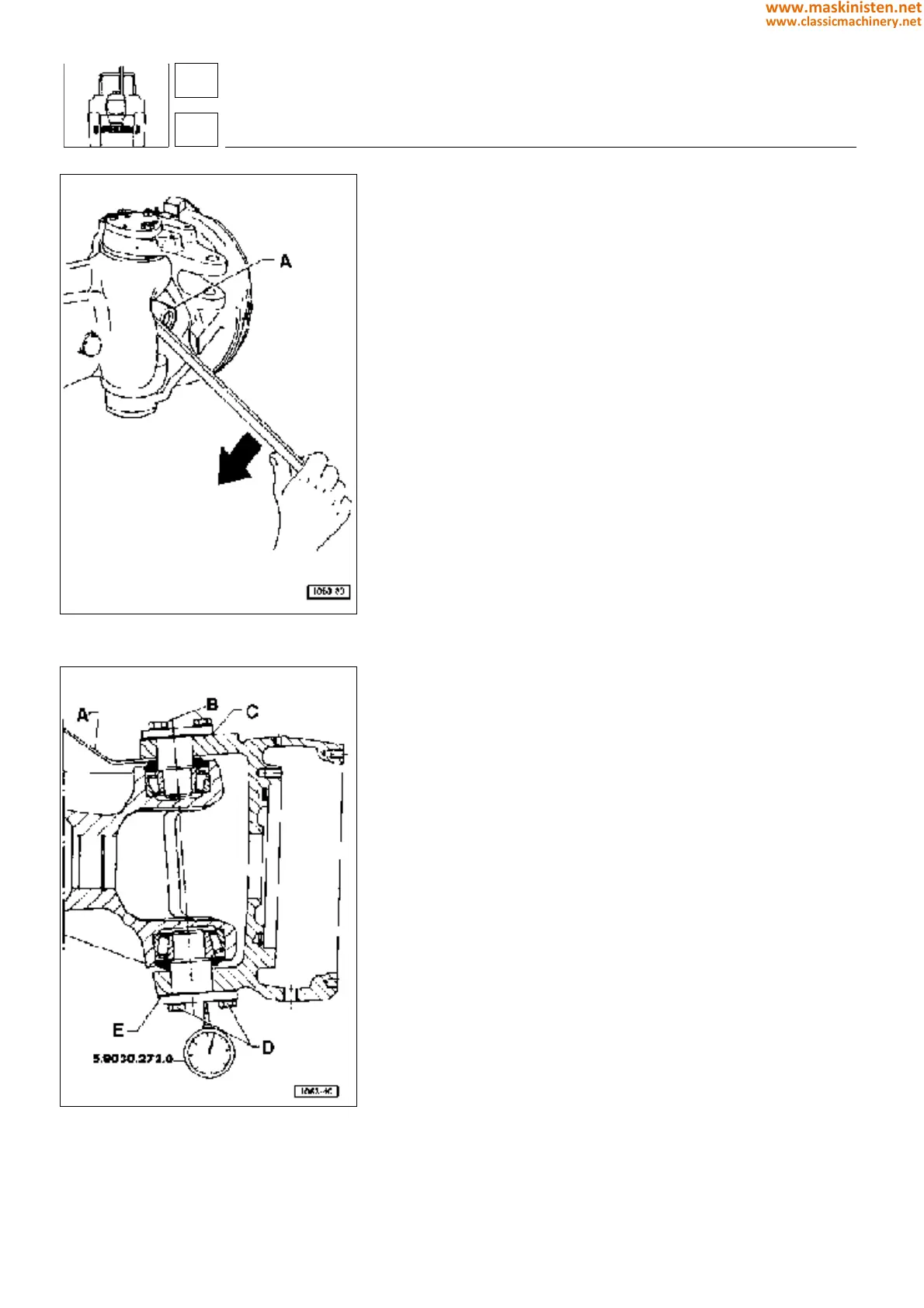

Fig. 13 - Checking wheel hub clearance.

A - Lever

B - Screws

C - Pack of shims

D - Screws

E - 0.5 mm shim.

The following procedure should be observed on

reassembly:

1 - Brakes

Replace the brake control piston O-rings and insert piston in its

seat with the oil grooves turned outwards.

2 - Final epicyclic reducer

Install the final epicyclic reducer holding the axle shaft in position

as shown in figure 12 by prising on cross journal A outwards; this

to prevent the axle shaft from moving inwards.

3 - Axle shafts

When inserting the axle shaft pay attention not to damage the

roller bearing or the seal ring. The axle shaft end should be

correctly introduced into the differential gear planetaries. Make

sure the axle shaft is free to rotate without any hindrance.

4 - Forks

After installing the bearings and the dust rings mount the fork by

placing one 0.5 mm shim under the lower pin, then fit the pin, use

a hammer if necessary, finally tighten the securing screws.

Fit a pack of shims thicker than the one taken on removal under

the upper pin. Install the pin tightening the securing screws.

Adjusting wheel fork bearing preloading

In the pack of shim to be put together for adjustment it is always

advisable to group more shims in one: as an example, it is better

one 0,2 mm shim be used instead of two 0,1 mm shims.

Fit no. 5.9030.267.0 magnetic base with no. 5.9030.272.0 centesi-

mal dial gauge onto the drive axle and then place the gauge feeler

perpendicularly to the lower pin close to centre and set to zero.

Using lever A as shown in figure, move the fork fully upwards and

read the clearance on gauge dial. Loosen the two screws B and

remove shims from pack C so that any clearance may be taken

up without preloading the bearings.

WARNING: The clearance amount should be reduced gradually

by repeating reading with the dial gauge each time so that the

bearings are not preloaded.

After all clearance has been taken up, remove a 0.10 to 0.15 mm

shim pack, so that a correct bearing preloading can be obtained.

Tighten screws B and D to the specified torque.

After correctly performing adjustment, ensure the shaft taper roller

bearing slide in their seats freely, even though a slight preloading

is felt.

drive axles - axles

4-W.D. front axle

43

4

200

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...