Fig. 1 - Before assembling the engine clean the block proper-

ly, fit all plugs and fasten it to no. 5.9030.491.4 swivel bench,

then install the cooling nozzles positioning them as shown on

page 22;

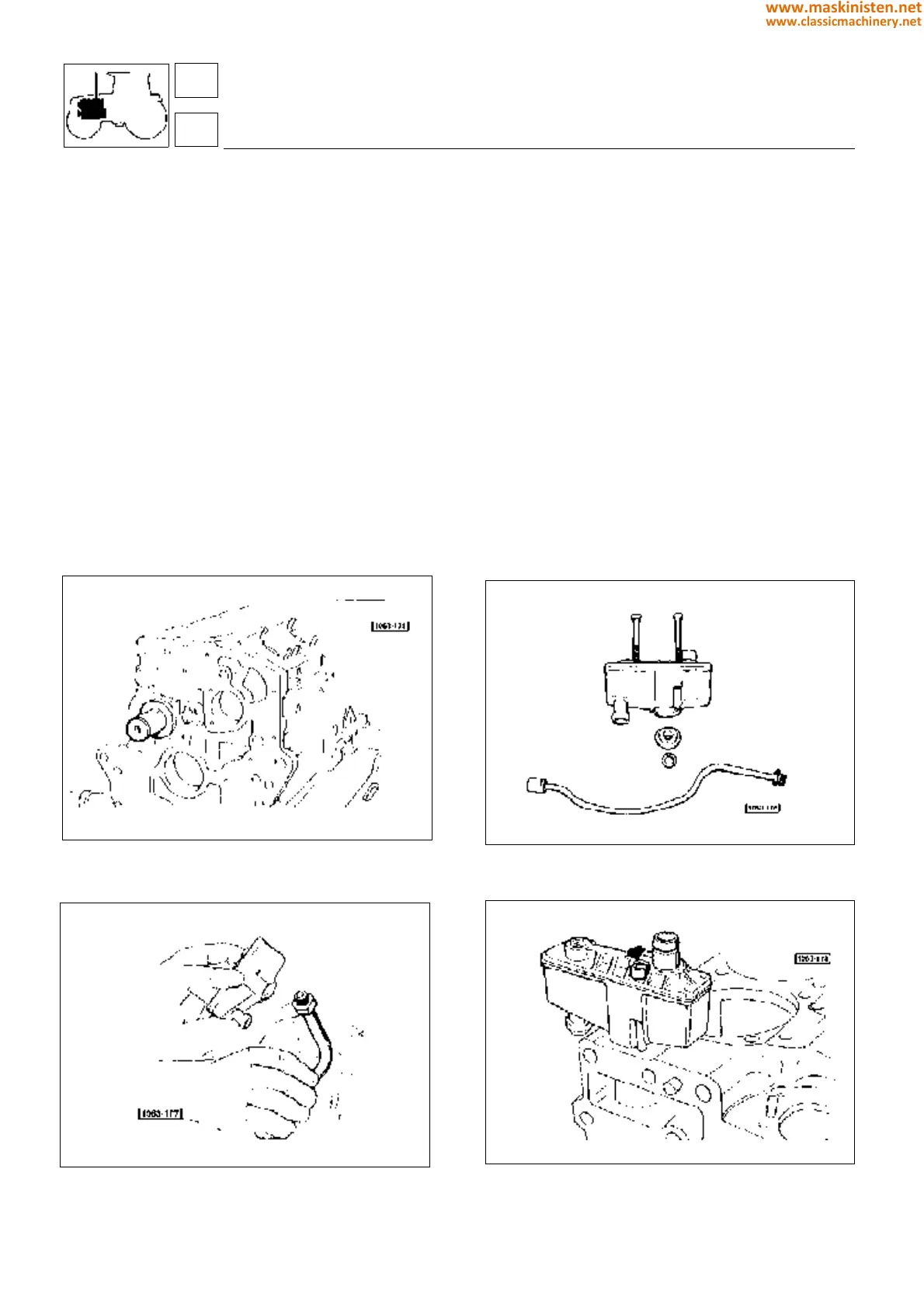

Fig. 3 - Fit the breather unit pipe providing oil return to engine

into the cylinder block;

Fig. 2 - Components of the engine oil vapour breather unit;

Fig. 4 - Install the oil vapour decantation unit in the engine

block using the two securing screws;

Instructions for engine assembly

Be sure all plugs have been removed, then carefully clean the cylinder block and the lubricating passages with cleaning

solvent and afterwards perform drying using compressed air

All sealing rings and gaskets should be replaced on assembly.

The use of proper tools is of prime importance to the correct performance of all mechanical operations.

Prior to reassembly use some engine oil to lubricate the faces of all components subject to relative motion.

The use of special grease is needed for some components so as they can be correctly held in position and assembly

operations facilitated.

Pay particular attention to the direction of assembly of some items by directly referring to the exploded views illustrated.

WARNING: Before refitting the engine you must lubricate the following parts:

— cylinders (internal surface);

— pistons;

— crankshaft (main journals and crankpins);

— connecting rods (small end bearing for gudgeon pin);

— valves (stems);

— rocker arms (bushes);

— oil pump and governor drive shaft;

— cam shaft (journals and cams);

— oil pump control rod and bevel gear drive.

engine

assembly

1

92

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...