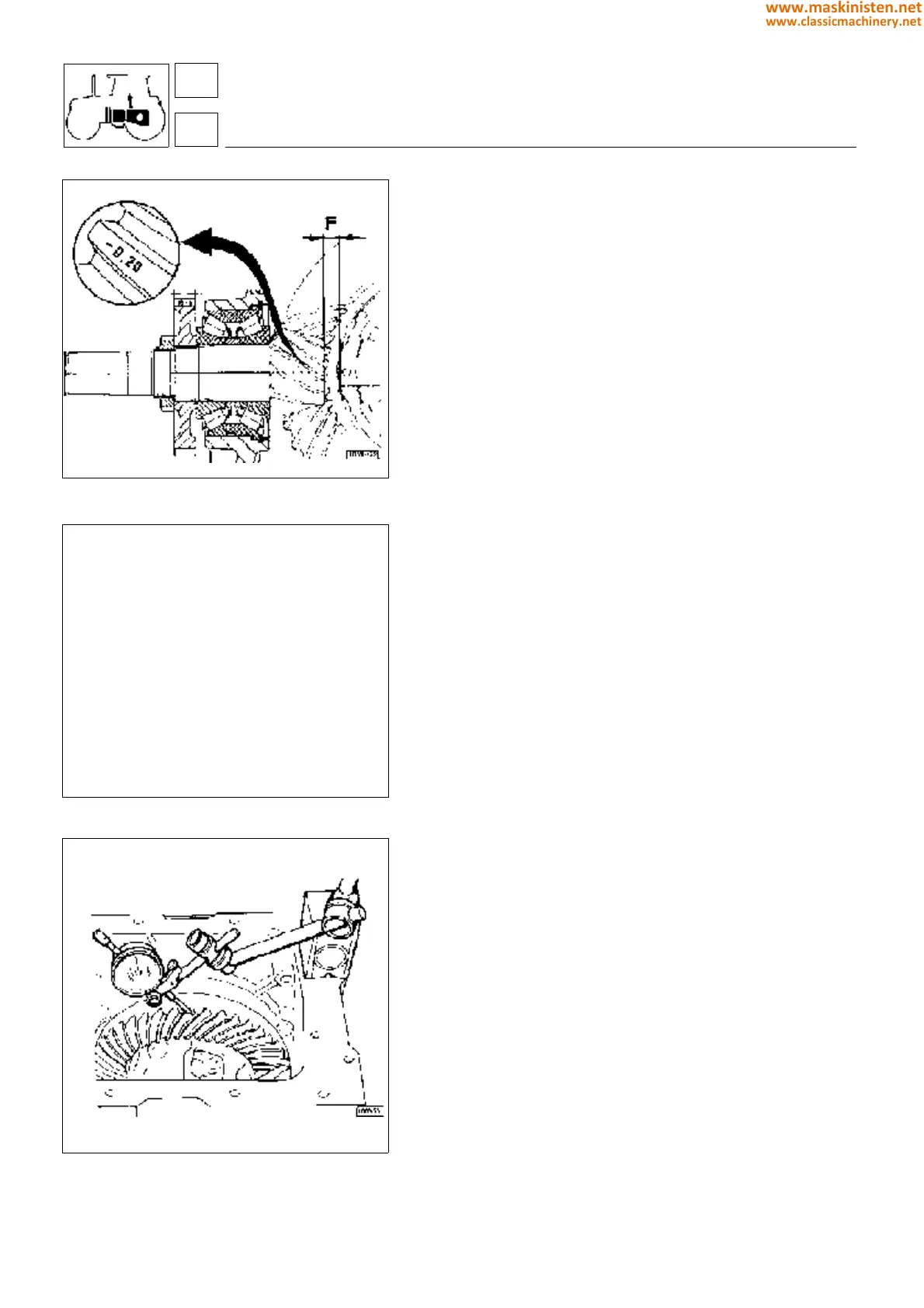

Fig. 37 - Value stamped on a tooth of the pinion.

Fig. 38 - Select circlips of suitable thickness for

the amount of bevel pinion play.

Adjusting the bevel drive (see figs. 40 and 41)

Fit the pinion in the gearbox casing together with the bearing pack

A (without interposing shims), install gear B and tighten the lock

ring to a torque of : 44

÷

48 Kgm (440

÷

480 Nm).

Fit the differential case without the crown wheel; install shims for

the tapered roller bearings D and E so that they rotate freely in

their seatings but a slight preload can be felt; then install a shim

of thickness 0.1 mm. to preload the bearings.

Adjust the distance F between the differential case and the head

of the pinion by installing shims in position G indicated in figure

40; the exact measurement of this adjustment is obtained by

adding or subtracting the value stamped on the side of one of the

pinion teeth to the value of: 4 mm (models not equipped with SBA

system) or 2.5 mm (models equipped with SBA system).

The bearing assembly is held in position C by a circlip (selected

from those supplied in oversizes from 3.4

÷4.

1 mm. (see figure 38)

to fit perfectly in the bearing seating and prevent all bearing play.

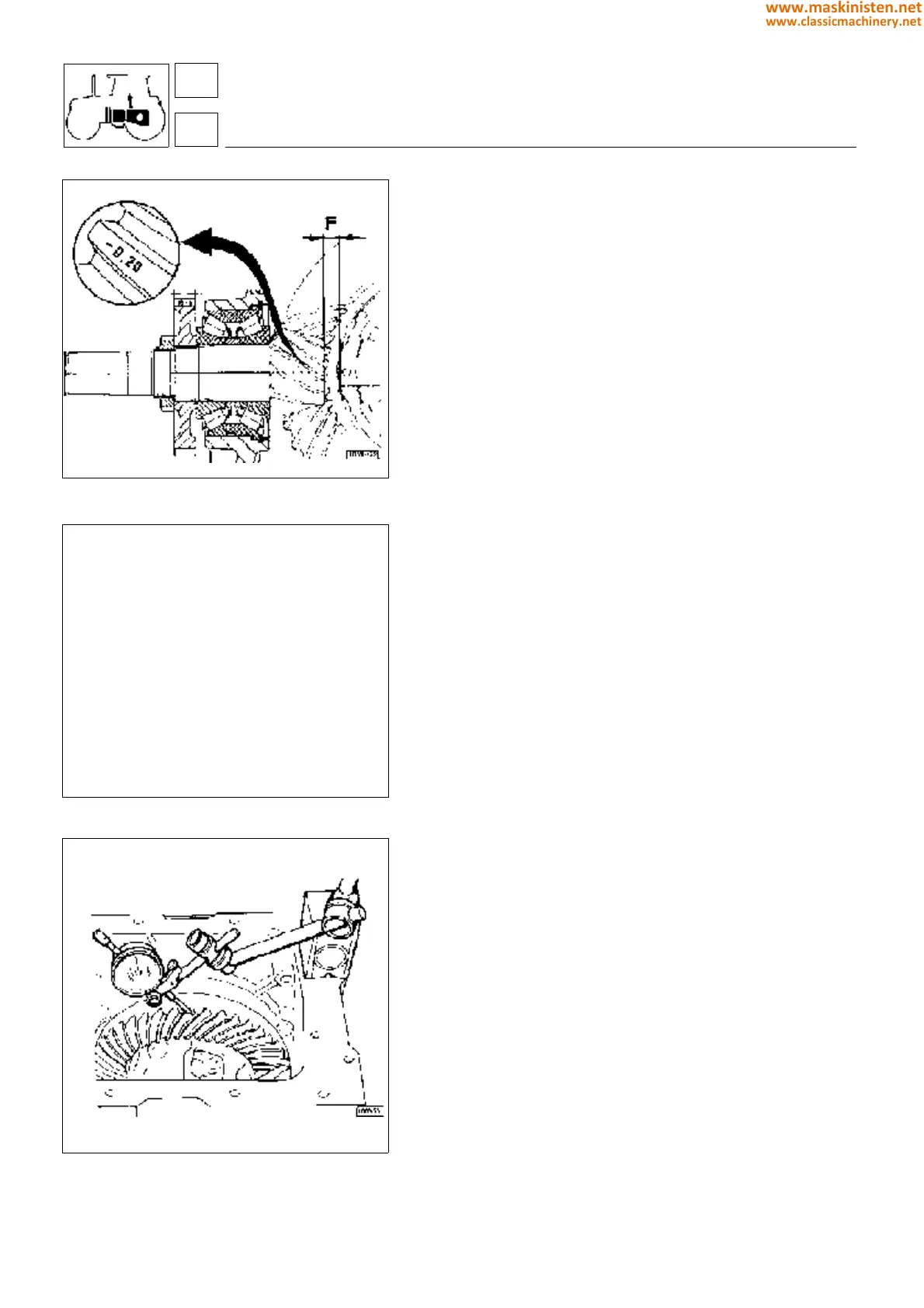

Fit the crown wheel to the differential case and, using a dial gauge,

measure the backlash between the pinion and the crown wheel;

the backlash should be between 0.18

÷

0.24 mm (see figure 39),

if not, remove shims from the pack D and add them to pack E to

bring the crown wheel closer to the pinion, or vice versa to move

it further away.

NB: On completion of bevel drive adjustment, slacken off the ring

nut, apply Loctite 270 to the thread, then re-tighten to a torque of

44

÷

48 Kgm (440

÷

480 Nm) and secure the pinion lock nut by

staking.

Tighten the crown wheel bolts to a torque of 10

÷

12 kgm (98

÷

117).

Refitting the bevel drive without replacing any

components

No adjustment is necessary. Fit the original shim packs and check

that the distance between the head of the pinion and differential

case is as specified.

Replacing the crown wheel bearings

Fit shims of a suitable thickness to obtain a bearing preload of 0.1

mm. This done, check the backlash between the pinion and the

crown wheel and adjust if necessary.

Replacing the pinion bearings

If one of the components is damaged, the entire bearing assembly

must be replaced (as the supplier will determine the configuration

of the assembly according to the dimensional tolerances) after

which the bevel drive must be adjusted.

Fig. 39 - Checking backlash between bevel pinion and

ring gear teeth.

transmission

differential gear

3

35

E - SNAP RING

2.1499.061.1 120X3,4

2.1499 062.1 120x3,5

2.1499 063.1 120x3,6

2.1499.064.1 120x3,7

2.1499.065.1 120x3,8

2.1499.666.1 120x3,9

2.1499.067.1 120x4,0

2.1499.068.1 120x4,1

154

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...