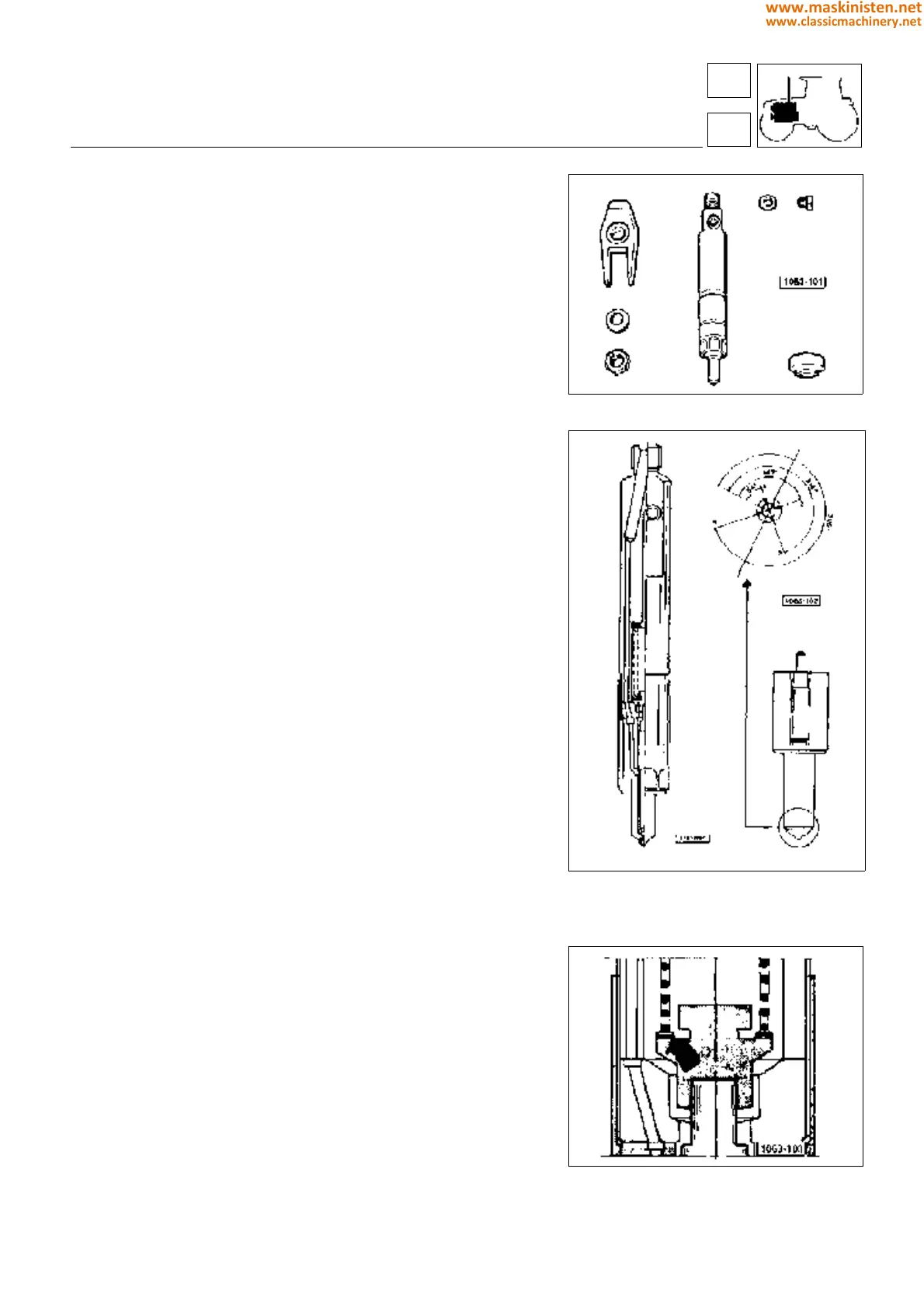

Fuel injection nozzles

Checking fuel injection nozzles

The checks on injection nozzle operating conditions include injec-

tion nozzle spraying efficiency and calibration.

However, it is recommended that the utmost cleanliness rules be

strictly observed and a thorough test on the hydraulic seal of the

different system fittings be performed. As a matter of fact even a

small leakage would invalid the tests carried out.

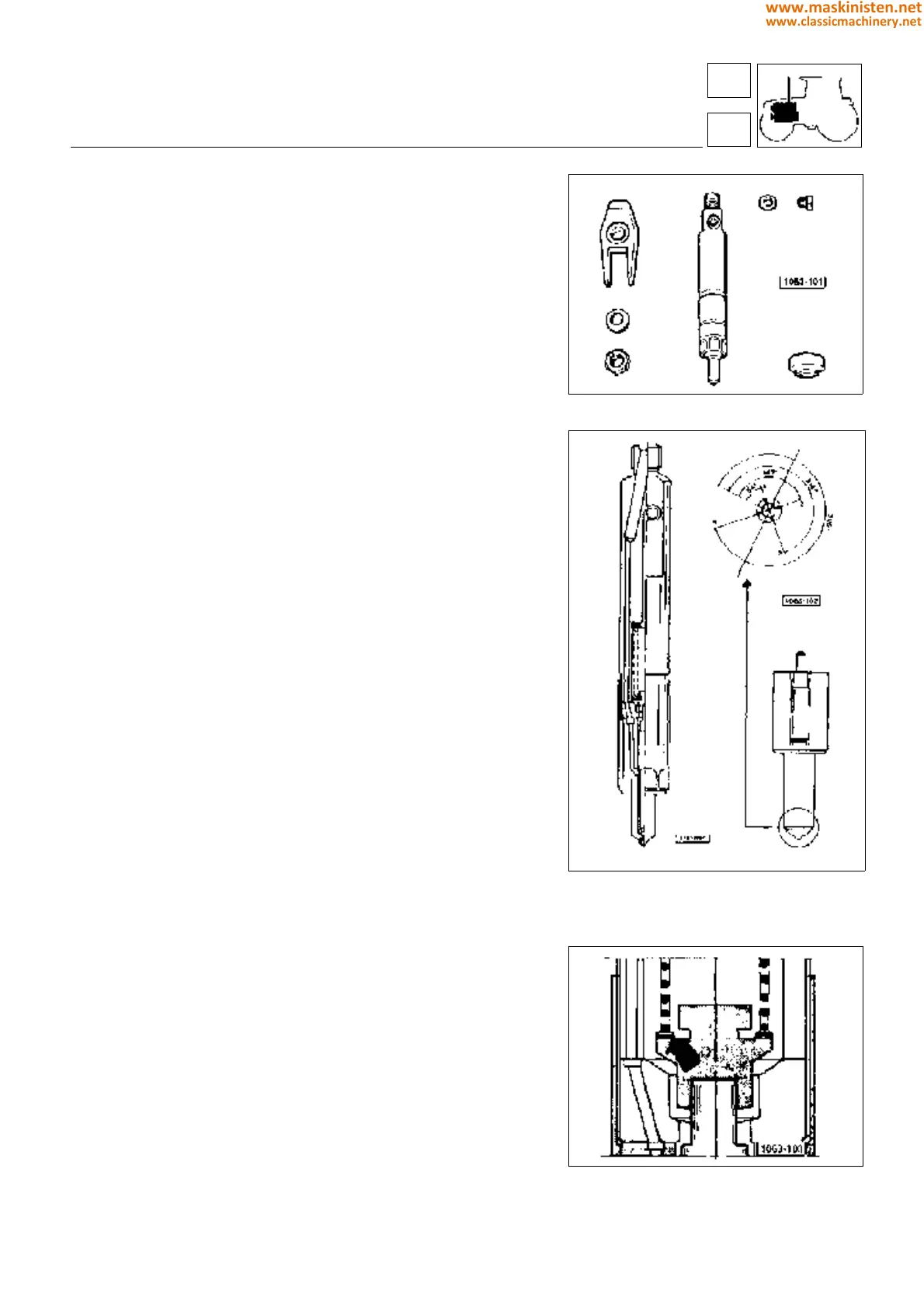

Injection nozzle calibration

Check pressure reading at which the nozzle needle begins to be

lifted from its seat thus determining the injection starting.

This pressure should be within the recommended specifications.

For this reason, each time that calibrating pressure readings differ

from specifications the injection nozzle should be adjusted as

required.

To perform the above checks, the use of a pump connected to the

injection nozzle to be tested by a piping is unavoidable.

(Prior to performing the test the fuel recovery plug should be

removed).

The following procedure shall apply:

Operate the pump lever (fig. 4) a few times to force any air out of

system.

Slowly operate the pump lever and notice the pressure reading

right in the moment the injection begins. This pressure should be

180 bar. If readings differing from that specified are indicated, it

will be necessary to adjust the pressure spring by simply adding

or removing the special spring preloading shims.

To gain access to spring adjustment, remove first the lower cap

of the injection nozzle holder and then add or remove shims

bewteen spring and flat cap until the desired nozzle calibrating

pressure is obtained.

Fig. 1 - Injection nozzle assembly.

Fig. 2 - Injection nozzle section.

Fig. 3 - Spring load adjustment.

engine

fuel system

16

1

53

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...