Engine air filter

Warning

It is important that the warning light, which shall be lit when the air

filter is clogged, is always working efficiently. This check can be

carried out by starting the engine and briefly blocking the air intake

pipe by means of a plug (never touch it with your hands).

The filter cartridge should be thoroughly clean, if not, it shall be

cleaned or washed.

Cleaning with compressed air

This method is used when the filter cartridge is clogged with dust.

Direct a compressed air jet at a maximum pressure of 7 bar from

the inside outwards of the filter cartridge, afterwards blow the air

over the whole surface by moving the air jet along the foldings in

the paper until all dust has been removed.

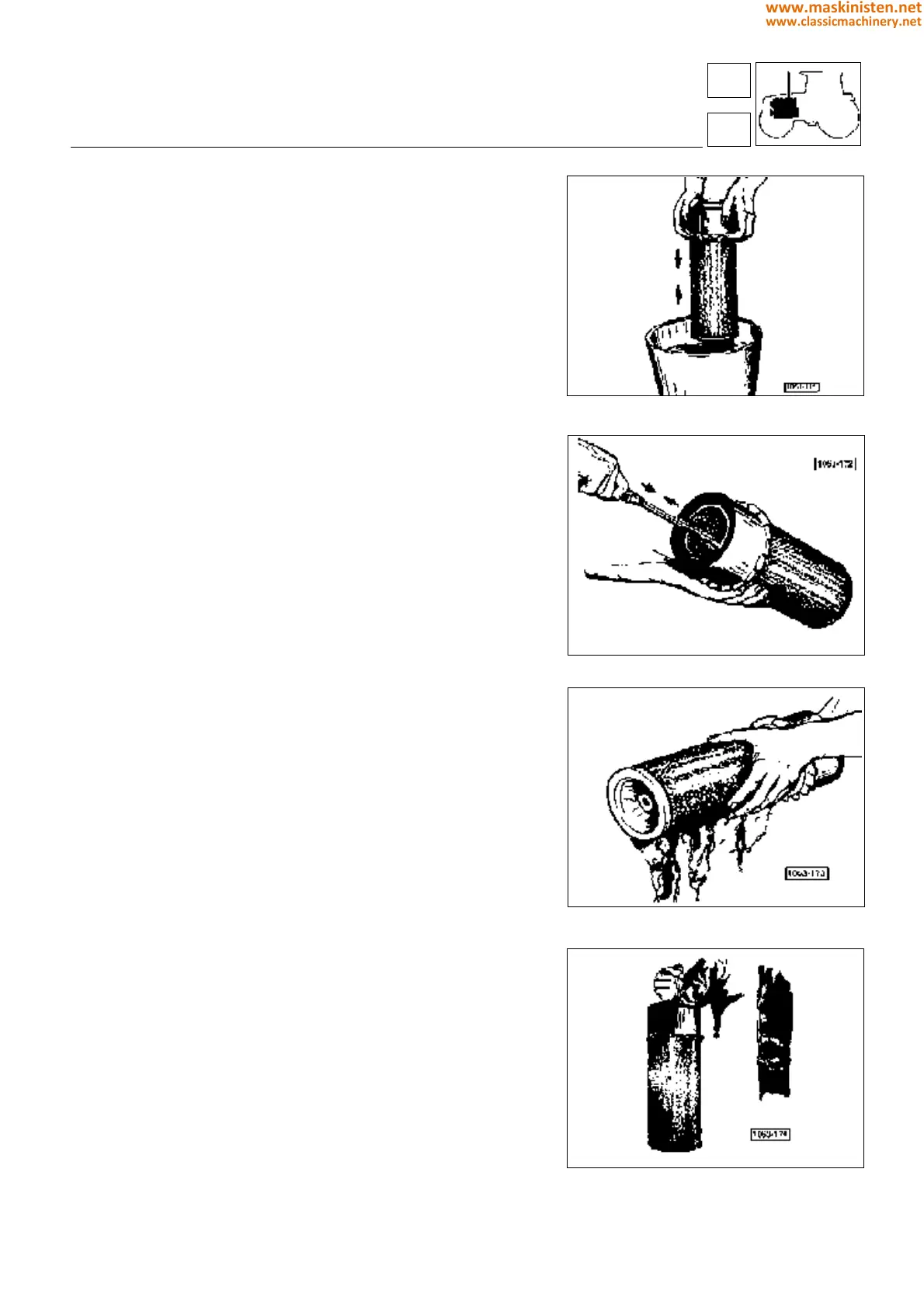

Washing with water

This method is particularly recommended when the filter cartridge

is obstructed by oily substances and consists of washing the filter

cartridge in clean water.

Rinse the cartridge with a jet of water directed from the inside

outwards at a maximum pressure of 3 bar.

Let the cartridge dry 24 hours at room temperature in a dust-free

environment.

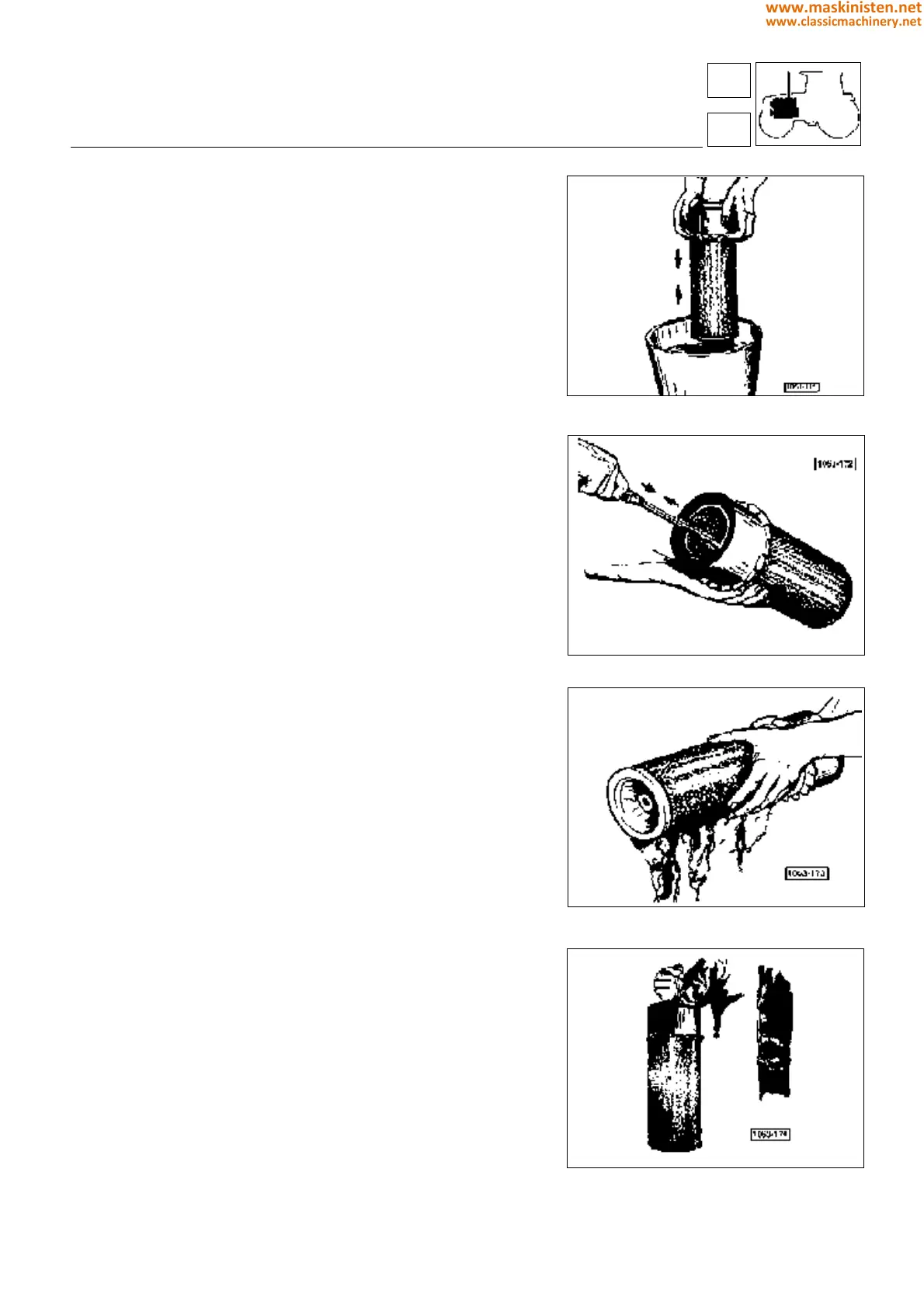

Reassembling the cartridge

Clean the inside of the filter body with a dry cloth and make sure

that the cartridge has not become deformed in any way.

Also check that the paper of the filtering cartridge is not torn by

introducing a light source into the cartridge interior and visually

inspecting its outside surface to see if any light shows through. If

no light source is available, carefully examine the external surface

of the cartridge folded paper.

Should any holes or tears be found, regardless of their size, the

filter cartridge should be replaced at once.

The inner safety cartridge should never be cleaned but only

replaced every six times the main cartridge is cleaned.

Fig. 11 - Washing the filter cartridge.

Fig. 12 - Cleaning the filter cartridge with com-

pressed air.

Fig. 13 - Using a water jet to remove any residual

left on the filter cartridge.

Fig. 14 - Using a light source to check the filter

cartridge folded paper conditions.

engine

intake and exhaust system

18

1

91

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...