Steering wheel shaft

Verify the integrity of the steering column, and in particular, make

certain that the surfaces of the bearings are not scored, also that

the splines are neither damaged nor showing signs of excessive

wear.

Do not grease or oil the bearing inside the sleeve.

Check that the steering column rotates freely, without sticking, but

also without excessive play.

Before refitting the rubber boot A (Fig 4), smear the steering column

B with the specified grease at the position indicated in fig 4.

Having tightened all components, check that the steering wheel

continues to operate correctly even when at its two height adjust-

ment limit positions (fully raised and fully lowered).

Steering cylinders

Clamp the cylinder in a vice and withdraw the piston E (fig. 7);

If necessary, remove the circlip F (fig. 8) from its groove with the

aid of a suitable tool to allow withdrawal of the ball end G (fig. 8).

If necessary, remove the seal (C - fig. 7) from the cyilinder with

the aid of a screwdriver.

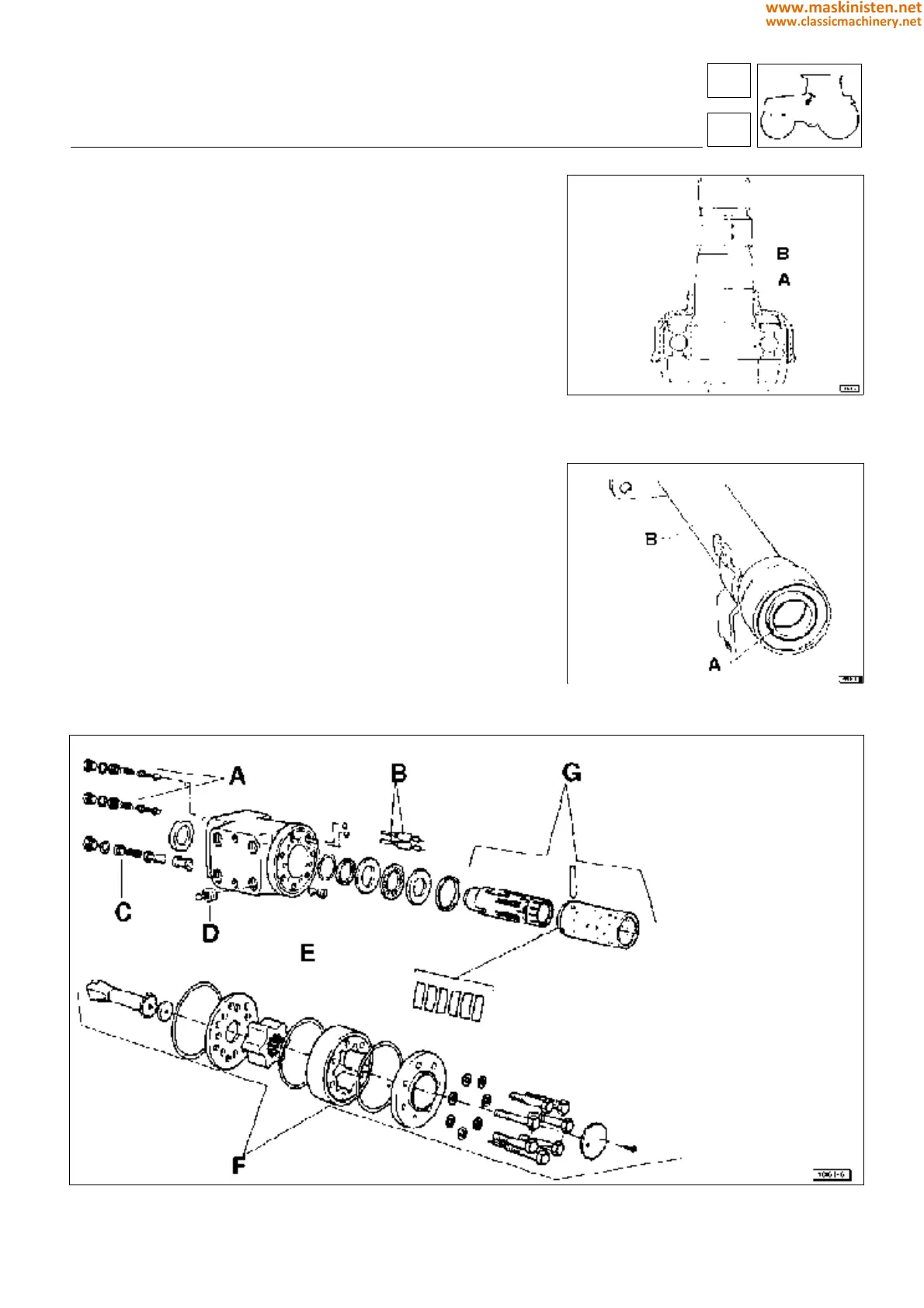

Fig. 6 - Components of directional control valve.

Fig. 4 - Section through steering wheel shaft

A Rubber boot

B Steering column

Fig. 5 - Steering column.

A Bearing

B Sleeve

controls

hydrostatic steering

A - Shock valves for reversible

driving position

B - Anticavitation valves

C - Pressure relief valve

(150 bar)

D - Emergency steering check

valve

E - By-pass valve (redirects

return flow to inlet)

F - Orbital pump unit

G - Directional control valve

63

6

295

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...