Section 15 SUSPENSION

Subsection 02 (DIRECT ACTION SUSPENSION)

SMR2003-045_15_02A.FM 15-02-3

Tilt seat upward.

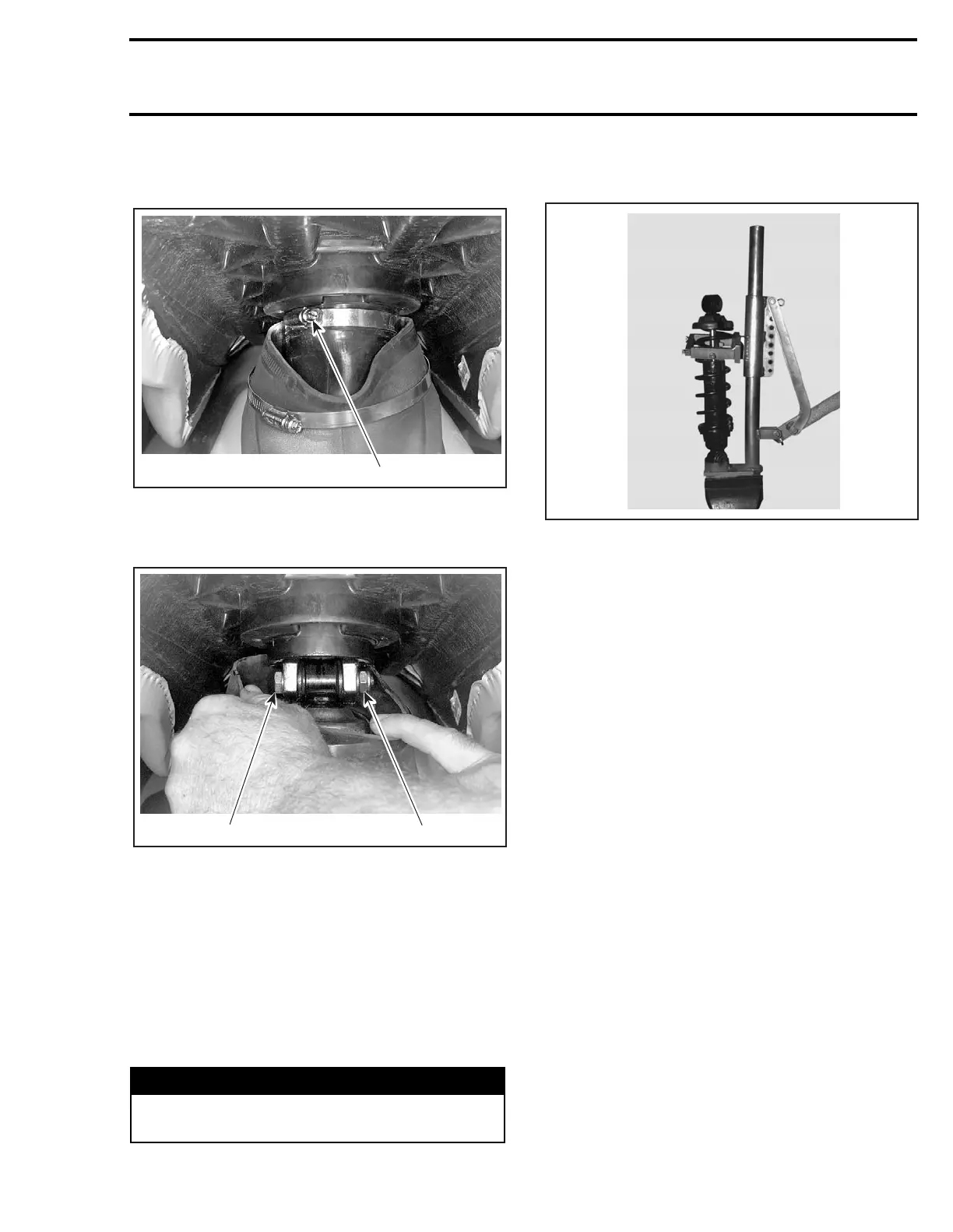

Loosen upper gear clamp no. 9 of inner boot no. 5.

1. Loosen gear clamp

Remove bolt no. 10 and lock nut no. 11 from shock

absorber upper support.

1. Bolt

2. Lock nut

Remove shock absorber/coil spring assembly.

Outer Boot

Pull outer boot to remove it from body.

Coil Spring

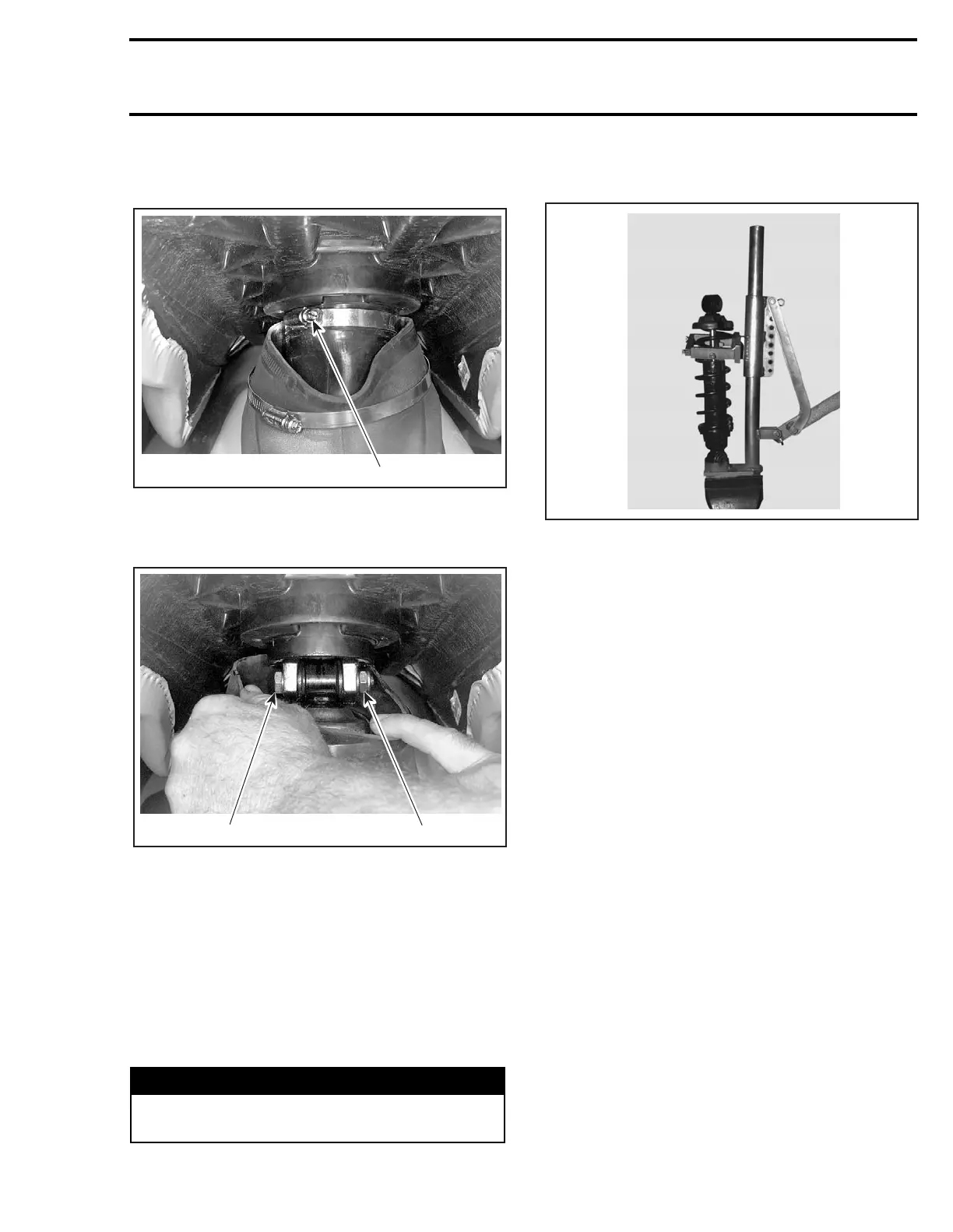

Install spring compressor tool (P/N 529 027 100)

in a vise.

Install shock absorber/coil spring assembly in

spring compressor tool.

Compress spring and remove cup no. 13.

Unload tool and remove spring from shock absorber.

INSPECTION

Boot

Inspect condition of boots. If there are any signs

of tear, renew boot(s).

Shock Absorber

Inspect shock absorber for wear. Extend and com-

press the piston several times over its entire

stroke; it should move smoothly and with uniform

resistance.

Pay attention to the following conditions that will

denote a defective shock absorber:

– A skip or a hang back when reversing stroke at

mid travel.

– Seizing or binding condition except at extreme

end of either stroke.

– Oil leakage.

– A gurgling noise, after completing one full com-

pression and extension stroke.

Renew if any defects are present.

ASSEMBLY

Assembly is essentially the reverse of disassem-

bly procedure. Refer to the main illustration at the

beginning of this subsection for torque specifica-

tions and service products to be used.

WARNING

Do not attempt to dismantle a spring without

using the proper tool.

F08L13A

1

F08Q04A

2

1

F05L0NA

Loading...

Loading...