6

Electrical installation

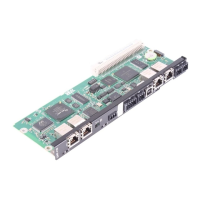

Terminal assignment and DIP switches

Manual – DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

35

Assignment: CAN1 system bus interface

No. Name Function

X33 1 DGND Reference potential for system bus CAN1

2 CAN1H System bus CAN1 high

3 CAN1L System bus CAN 1low

Connecting the system bus

INFORMATION

• The CAN 2 system bus is electrically isolated. We therefore recommend to use

the CAN 2 ( X32) system bus interface for connecting field devices (e.g. CANopen

inputs and outputs).

• The CAN 1 system bus is not electrically isolated. We therefore recommend to

use the CAN 1(X33) system bus interface to connect inverters via the system bus

in the control cabinet.

• A CAN system bus interface is required for communication between

MOVIDRIVE

®

MDX61B and the integrated controller.

The CAN system bus supports transmission systems compliant with ISO11898. The

"Serial Communication" manual contains detailed information about the CAN system

bus. This manual can be ordered from SEW‑EURODRIVE.

Cable specification

• Use a 2 × 2-core twisted and shielded copper cable (data transmission cable with

braided copper shield). IEC 60999 does allow clamping without conductor end

sleeves. The cable must meet the following specifications:

– Cable cross section 0.2 mm

2

– 1.0 mm

2

(AWG24–AWG18)

– Cable resistance 120Ω at 1 MHz

– Capacitance per unit length ≤40pF/m at 1kHz

Suitable cables include CAN bus or DeviceNet cables.

6.2.8 X34: COM1/COM2 (RS485) engineering interface

Function

You can connect one of the following devices to the COM1/COM2 (RS485) engin-

eering interface:

• Gearmotor with integrated frequency inverter MOVIMOT

®

• DOP11B operator panel

NOTICE

• There must not be any potential shift between the devices connected via the

RS485. Take suitable measures to avoid potential shift such as connecting the

device ground connectors using a separate cable.

• Dynamic terminating resistors are installed. Do not connect any external ter-

minating resistors.

22900055/EN – 08/2016

Loading...

Loading...