Clearing Malfunctions

GMS800 · Operating Instructions · 8013025 V1.2 · © SICK MAIHAK GmbH 59

Subject to change without notice

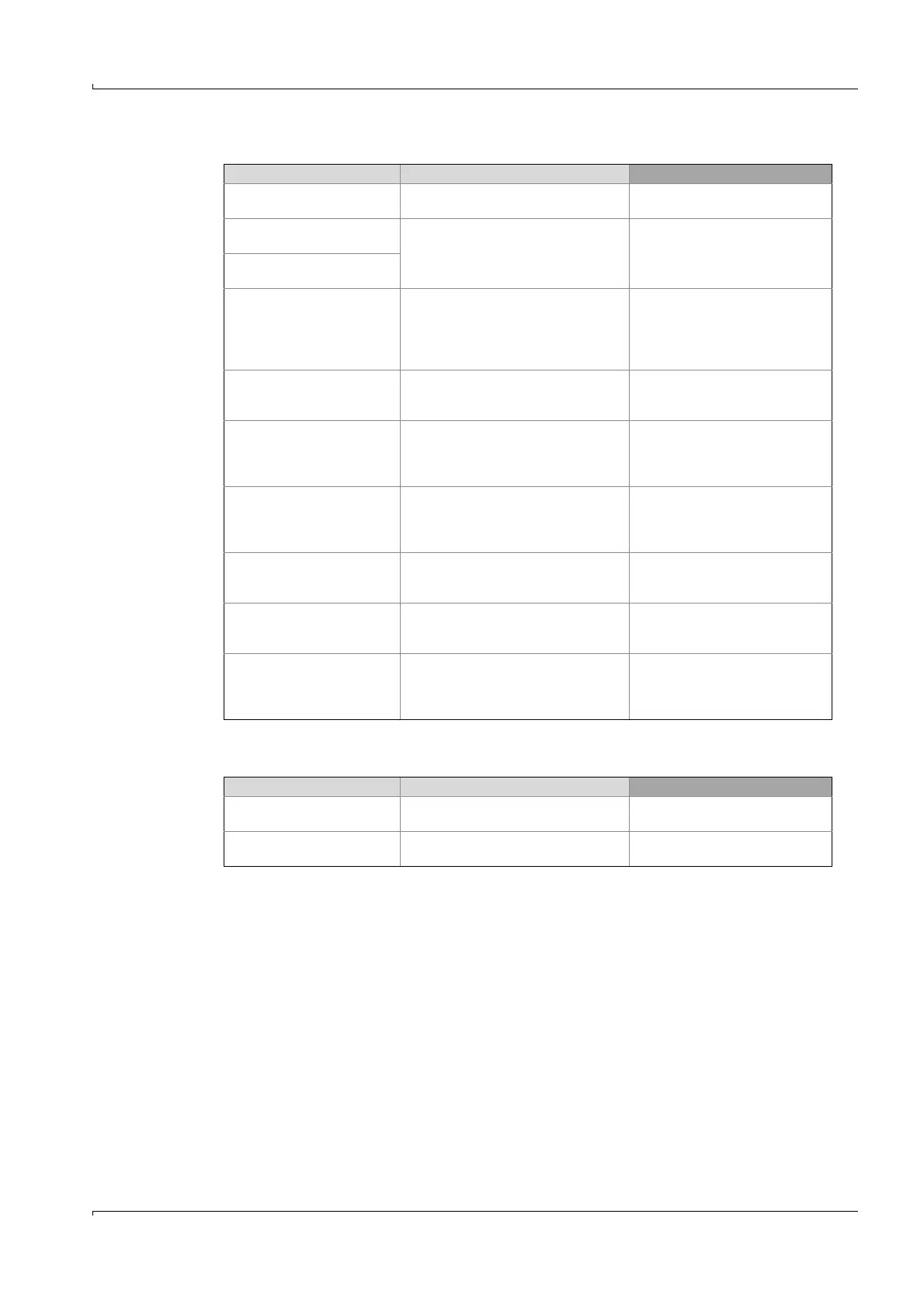

9.3 If measured values are obviously incorrect …

9.4 If measured values are unstable for no apparent reason …

Possible causes Information Notes for service

GMS800 not ready for opera-

tion.

b

Check operational readiness

(

→

p. 36, §5.3).

–

GMS800 not measuring the

sample gas.

b

Check sample gas path and all

valves (e.g. switching from test gas to

sample gas).

b

Make sure valves are function-

ing correctly, disassemble if

necessary.

Sample gas path not switched

correctly.

GMS800 not correctly

adjusted.

b

Check prerequisites for correct

adjustment:

– Correct test gases used?

– Nominal values set correctly?

b

Then run an adjustment.

b

Check test gases used critically

(nominal values, manufacturing

tolerance, state).

Measuring parameter settings

not suitable for the applica-

tion.

b

Check corresponding settings (e.g.

damping). try a different setting as

test.

–

Sample gas pressure inside

the GMS800 too high.

b

Ensure sample gas pressure in the

GMS800 is not greater than 20 kPa

(= 200 mbar) against atmospheric

pressure.

The gas pressure can influence

measured values in most of the

measuring principles used.

Sample gas path not gas-

tight.

b

Visually inspect the installation.

b

When a defect is suspected: Inform

the manufacturer's Customer Ser-

vice or trained skilled persons.

Carry out a leak tightness check.

When only observed on one

measured value output: the

load is too high.

b

Make sure that the total internal

resistance of the connected devices

is not larger than 500 Ω .

b

Measure including feed line.

Analyzer module is contami-

nated.

b

Contact manufacturer’s Customer

Service or trained skilled persons.

b

Inspect the measuring cell/

cuvette.

b

Clean or replace if necessary.

With computation of an ana-

log input (option): External

analog signal is erroneous or

has failed.

b

Check external equipment that deliv-

ers the analog signal for cross-sensi-

tivity compensation.

– Connection interrupted?

– Problem with external measure-

ment?

– External analyzer not adjusted?

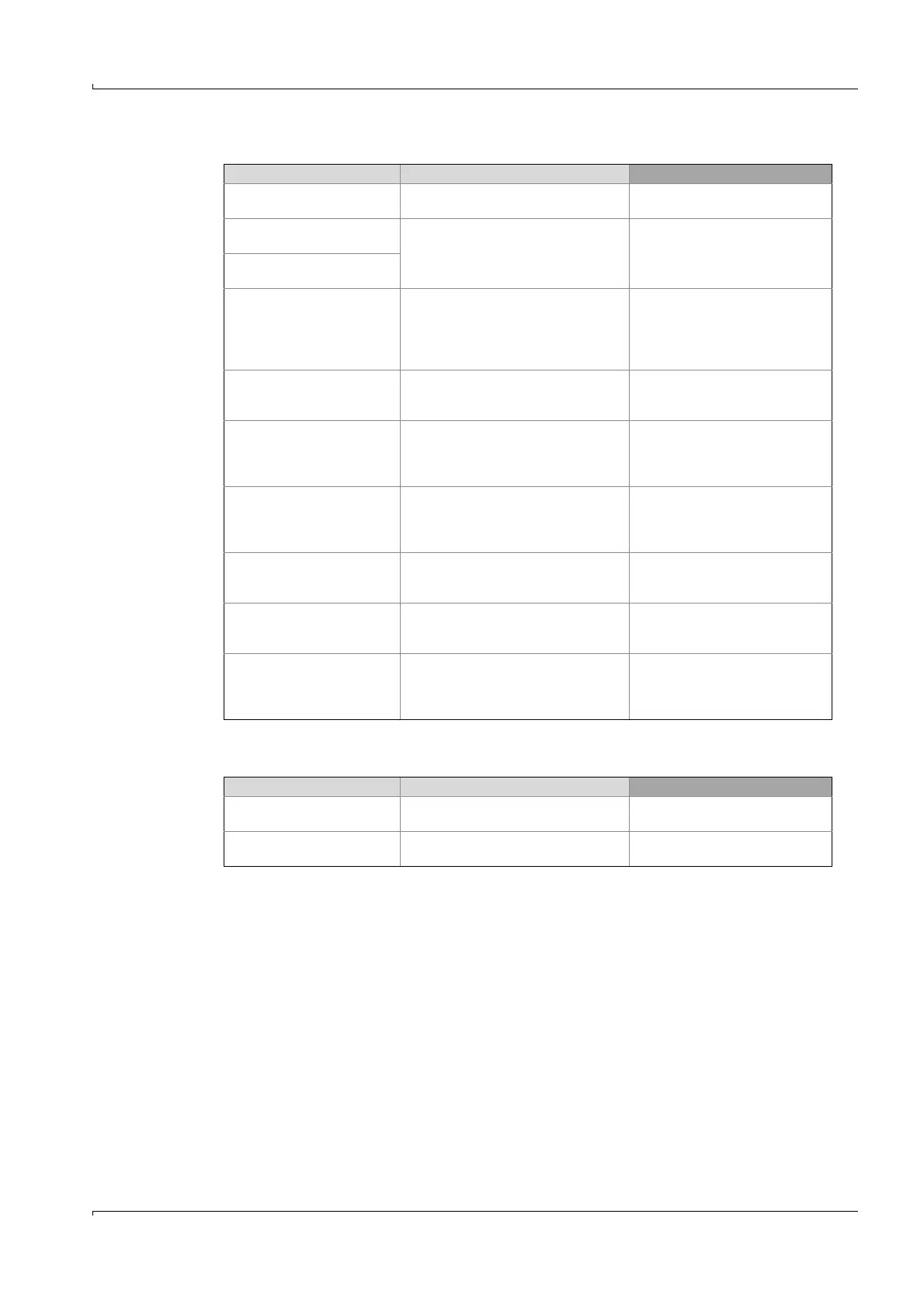

Possible causes Information Notes for service

Strong pressure fluctuations

at the sample gas outlet.

b

Install separate exhaust gas line for

the GMS800 .

–

Strong mechanical vibrations.

b

Check ambient conditions where the

GMS800 is installed.

–

Loading...

Loading...