GM35 Operating Instructions

Probe Model

Commissioning

50 © SICK MAIHAK GmbH • Germany · All rights reserved 8009389/07-2006

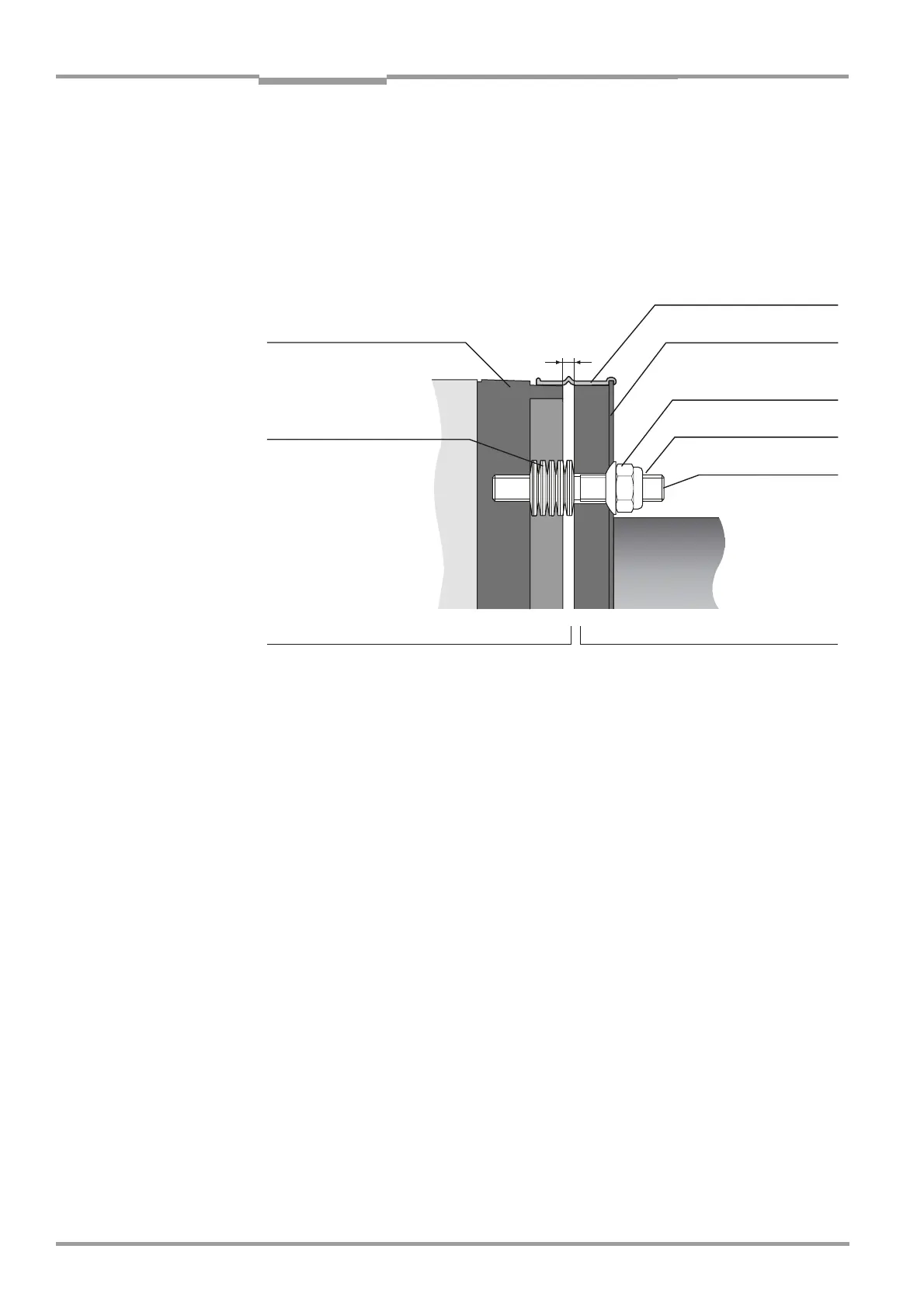

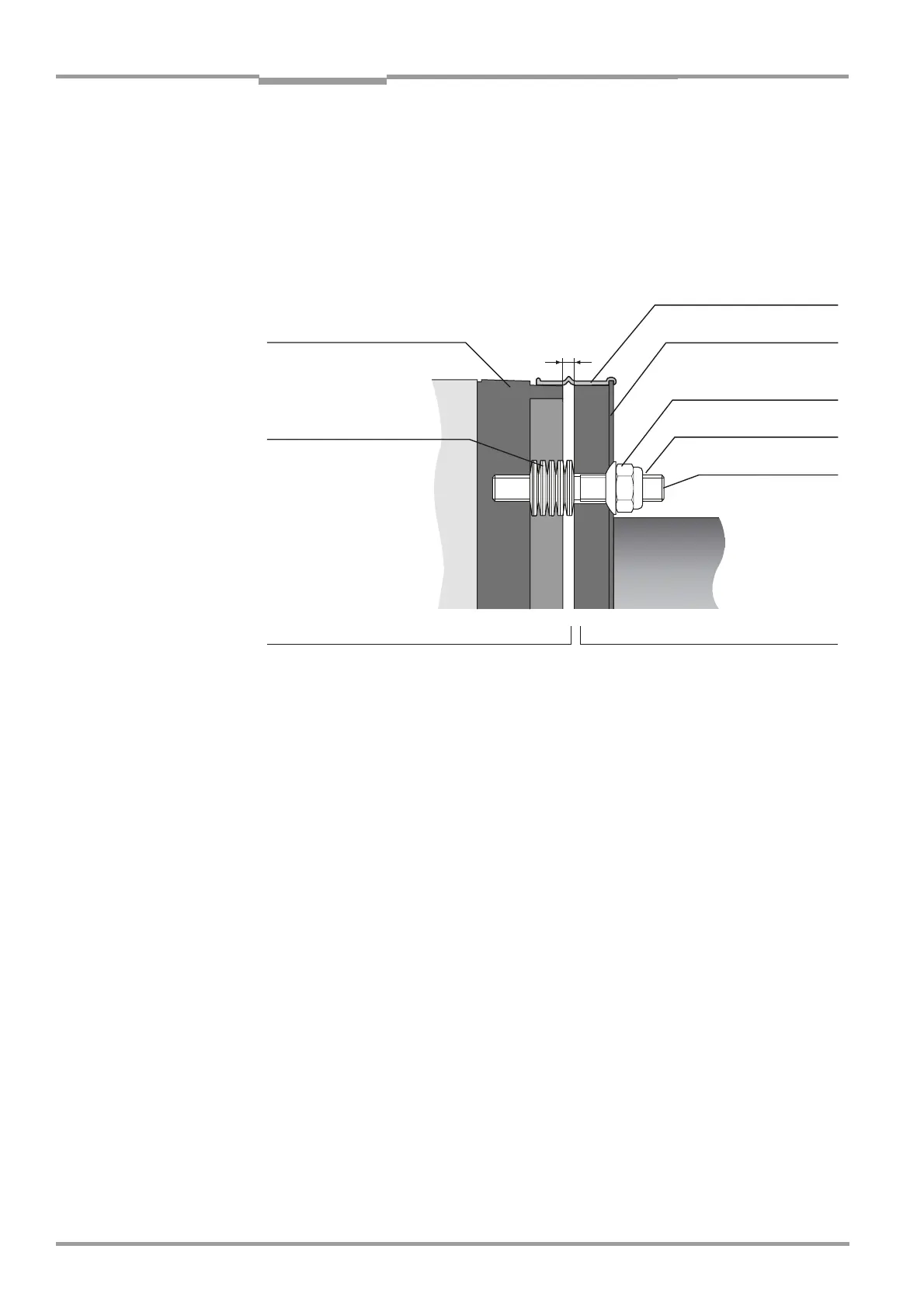

‡ Fit the centering washers and tighten the nuts using a 19 mm wrench so that the disk

springs are pressed together slightly.

A constant gap of approx. 3–4 mm should remain between the flange attachment of the

SR unit and the device flange of the measuring probe to allow adjustment of the optical

alignment (see Fig. 27).

‡ Close the gap with the sealing ring so that the ring rests on the smooth surfaces of the

flange attachment and device flange, as shown in Fig. 27.

Fig. 27 Cross-Chapter of the mounted connection between the SR unit and measuring probe

‡ If the flange attachment was removed from the SR unit, attach it again. Insert the hinge

bolt again and close the quick-release locks.

‡ Set the lever, at the probe flange, on the position “open” to unbar the closing device of

the probe for the measuring gas. See Fig. 3 "GMP measuring probe (with open slot)",

page 13 and Fig. 26 "Fixing the measuring probe on the SR unit (Fig.: GMP measuring

probe)", page 49.

6.4 Adjustments

6.4.1 Prerequisites and considerations

Choose the location for carrying out the adjustments

The GM35 must always be adjusted in an atmosphere that is free of the measurement gas

and dust. This means that it must be adjusted before it is installed. The only exception to

this are newly assembled installation environments that have not been put into operation

yet, whereby it can be ensured that the measurement gas duct remains flooded with

ambient air that is free of the measurement gas and dust while the work described below

is being carried out. In this case, a flange with pipe already mounted on the gas duct (which

has not been used yet) can act as a bracket while the adjustments are being made, whereby

the prerequisites for adjustments at the measuring point apply.

Note Adjustments or calibrations with test gases using a GPP-measuring probe represent a

special case; see Chapter page 81.

Flange attachment of the

SR unit

Disk springs:

10 per attachment, facing

each other (= 5 pairs)

Centering washer

Sealing ring

Device flange of the

measuring probe

Lock nut

Threaded pin of flange

attachment (fixed)

Measuring probeSR unit/flange attachment

3.5 ±0.5

Loading...

Loading...