Operating instructions Chapter 4

S100

8012238/YY30/2015-02-20 © SICK AG • Subject to change without notice 15

Due to its active scanning principle, the S100 does not require receivers or reflectors. This

has the following advantages:

Your installation effort is lower.

You can easily adapt the monitored area to the monitored area on a machine.

In comparison with contact sensors, electro-sensitive scanning is nearly wear-free.

4.3.2 Field set and switching fields

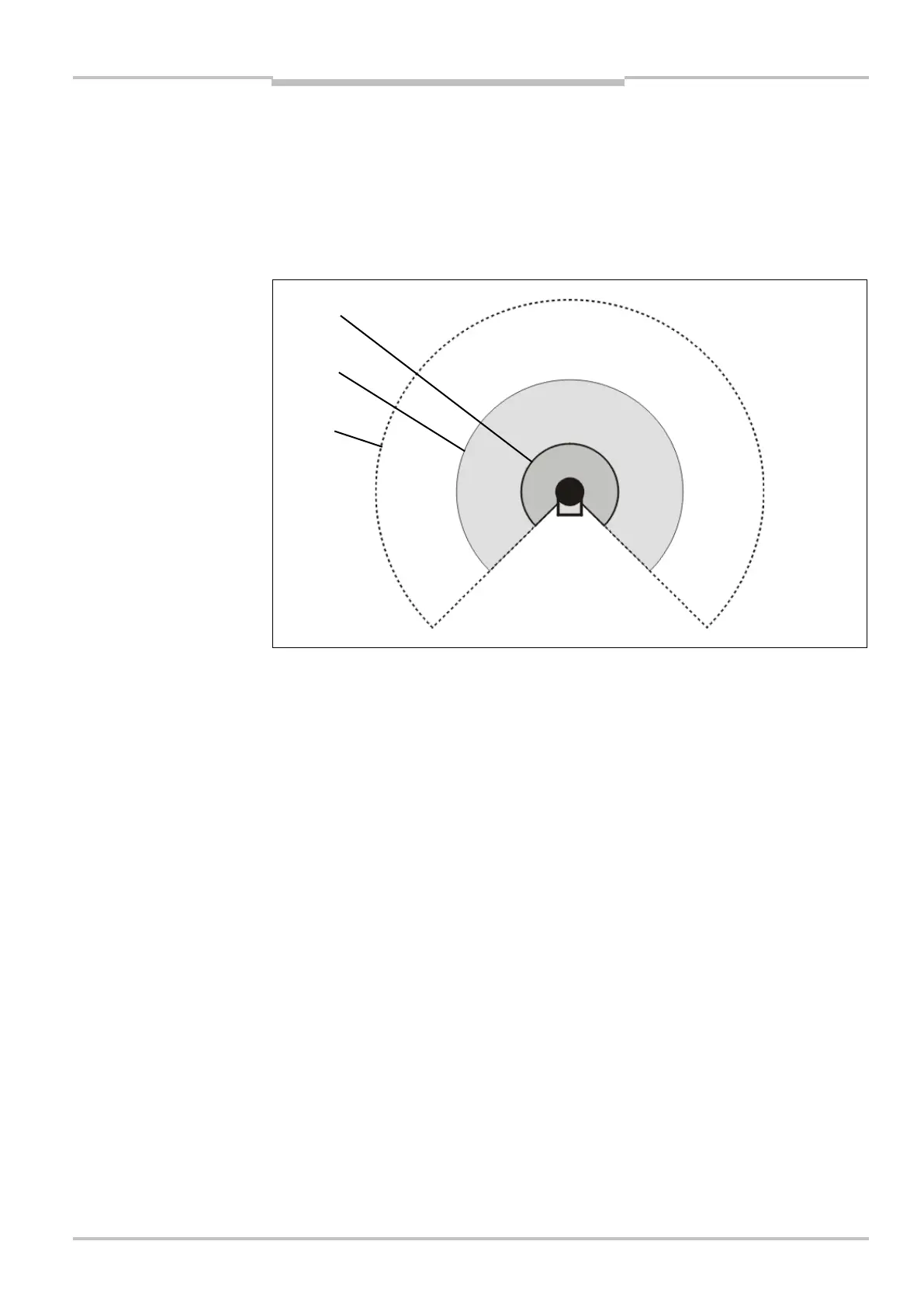

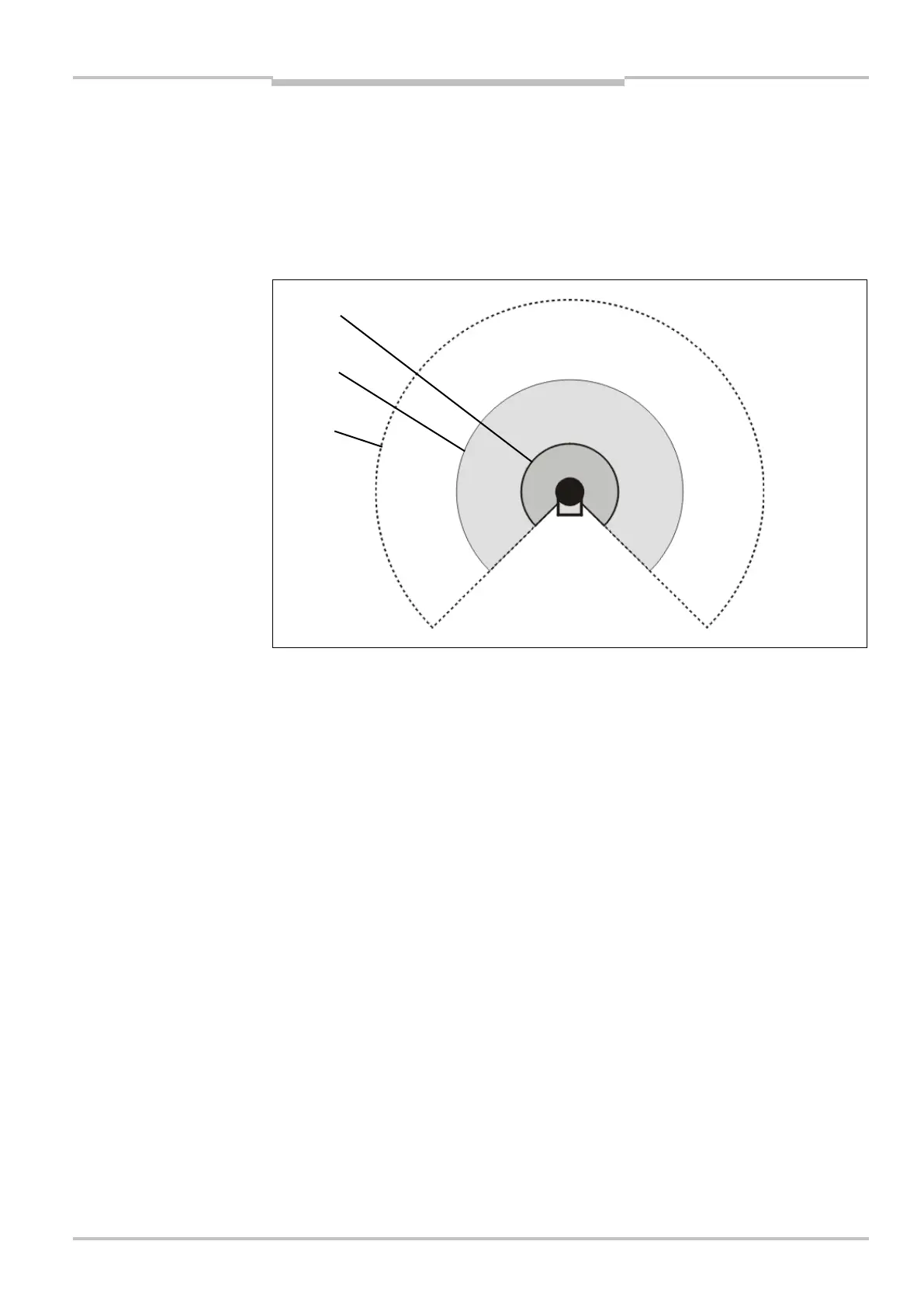

The S100 monitors areas on a machine or vehicle with its switching fields and . As

soon as the laser scanner detects an object in the switching field, it switches the allocated

output 1 or 2 to the OFF state.

You can, for example, define one of the two switching fields such that the laser scanner

detects an object before the actual monitored area is reached, e.g. for triggering a warning

signal.

The maximum distance at which the laser scanner can detect an object is defined by the

distance measuring range .

The two switching fields form a pair, the so-called field set. Depending on the variant used

(see section 4.2 under “S100 variants” on page 13), you can define up to 16 field sets

and save these in the laser scanner. In this way you can switch the S100 Professional

laser scanner to a different field set in case of a change in the monitoring situation (see

section 4.3.3 “Monitoring cases” on page 16).

You can configure and transfer these field sets to the S100 with the aid of the CDS-S100.

If the area to be monitored changes, then you can re-configure the S100 in software

without additional mounting effort.

Fig. 4: Switching field 1

and 2 as well as distance

Loading...

Loading...