3 Functions Issue 10/06

MICROMASTER 440 Operating Instructions

132 6SE6400-5AW00-0BP0

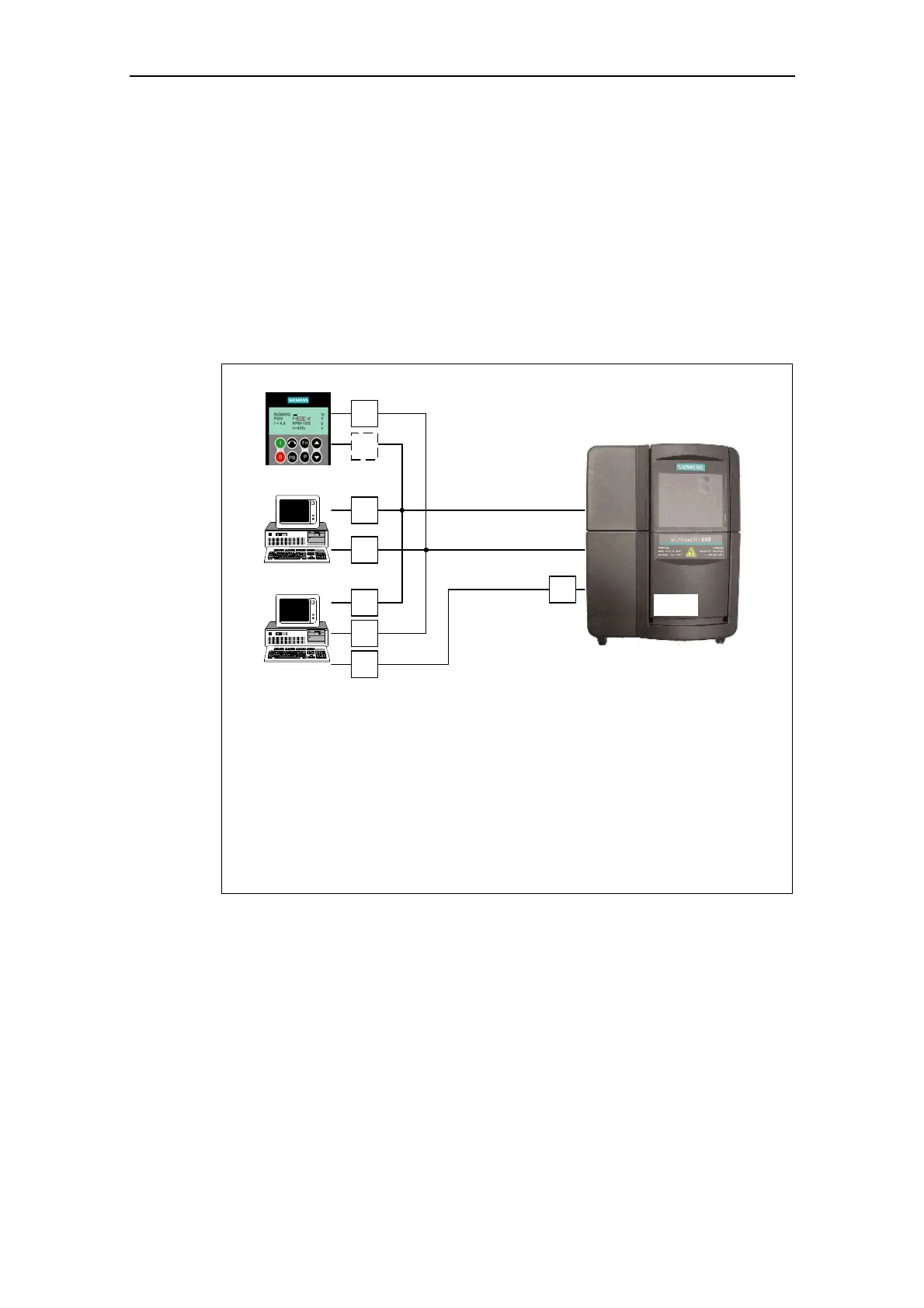

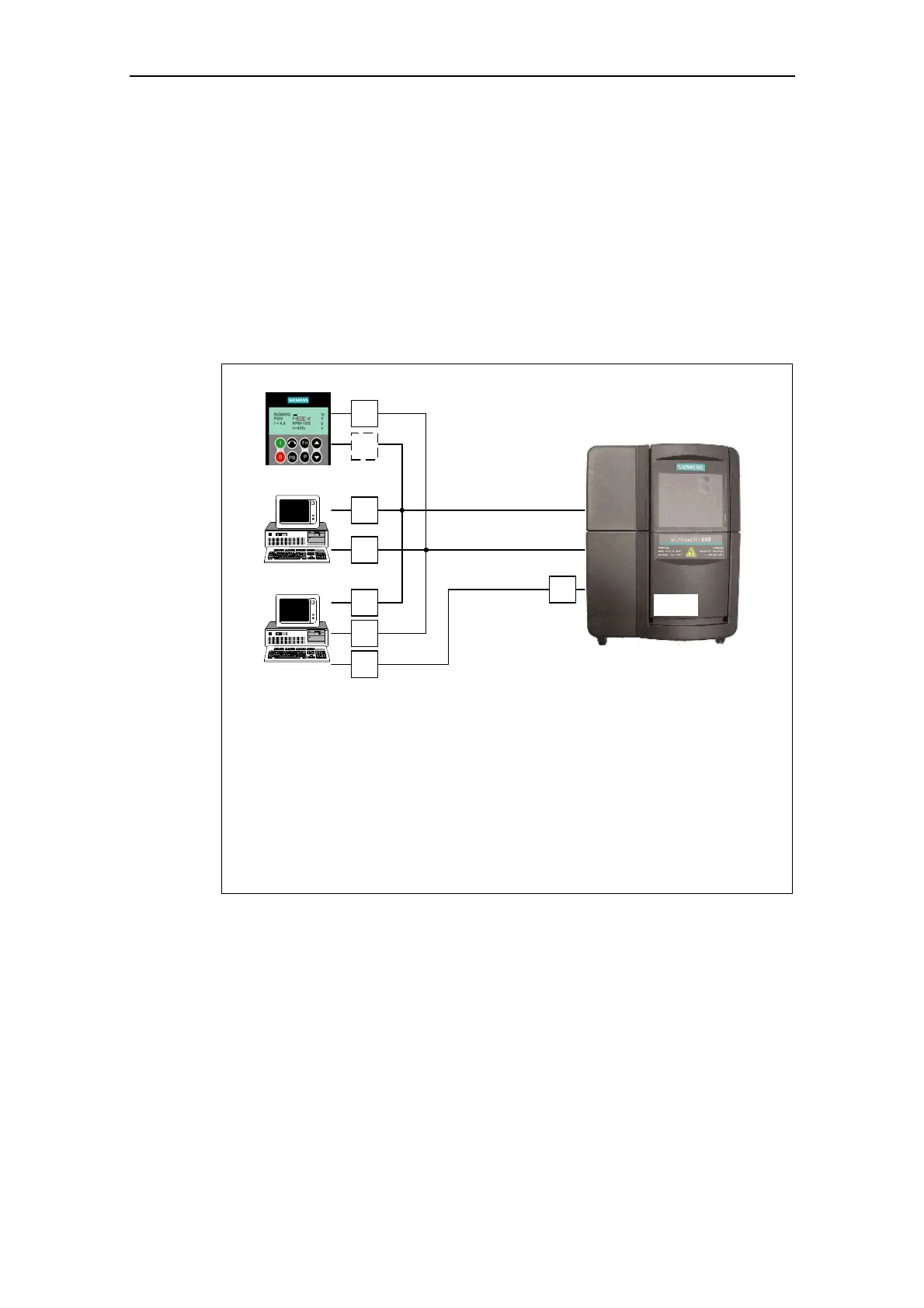

3.5.8 Series commissioning

The parameter set can be read-out (upread) from the drive converter via the serial

interface and saved on the hard disk / floppy disk or in a non-volatile memory (e.g.

EEPROM) using the following

¾ PC Tools (e.g. STARTER, DriveMonitor) or the

¾ Operator panel AOP

(please refer to Fig. 3-28).

The interfaces of the drive inverter with USS protocol and the fieldbus interfaces

(e.g. PROFIBUS) which can be used to transfer parameters, can be used as serial

interface.

DriveMonitor

AOP

STARTER

CB on COM link

USS on COM link

USS on BOP link

(PROFIBUS)

(RS485)

(RS232)

Parameter transmission from different

sources via download

MM4

* Option is absolutely required for the

connection

1)

1) Option: Operator panel door mounting kit

for single inverter control

5)*

2) Option: PC to inverter connection kit

3) Option: AOP door mounting kit

for multiple inverter control (USS)

4) Option: RS232-RS485 Converter

3)*

2)*

2)*

4)*

4)*

CB

5) With PROFIBUS:

SIMATIC NET

With CANopen or DeviceNet:

see user organisation

Fig. 3-28 Upread / download using AOP and PC Tools

If there is already an appropriate parameter set for the drive, which, for example,

was created by either upreading or by programming offline, then this can be

downloaded into the drive inverter. This means that it is possible to transfer the

parameter set from drive inverter A to drive inverter B which, for identical

applications (e.g. series machines, group drives) allows data to be copied and

therefore in turn fast commissioning.

Loading...

Loading...