Issue 10/06 3 Functions

MICROMASTER 440 Operating Instructions

6SE6400-5AW00-0BP0

223

3.20.2 Load torque monitoring

Parameter range: P2181

P2182 – P2192

r2198

Warnings A0952

Faults F0452

Function chart number: -

This function allows the mechanical

force transmission between the motor

and driven load to be monitored.

Typical applications include, for

example, pulley belts, flat belts or

chains, or pulleys for toothed wheels

of drive-in and drive-out shafts which

then transmit circumferential

velocities and circumferential forces

(refer to Fig. 3-87). The load torque

monitoring function can then detect

whether the driven load is locked or the force transmission has been interrupted.

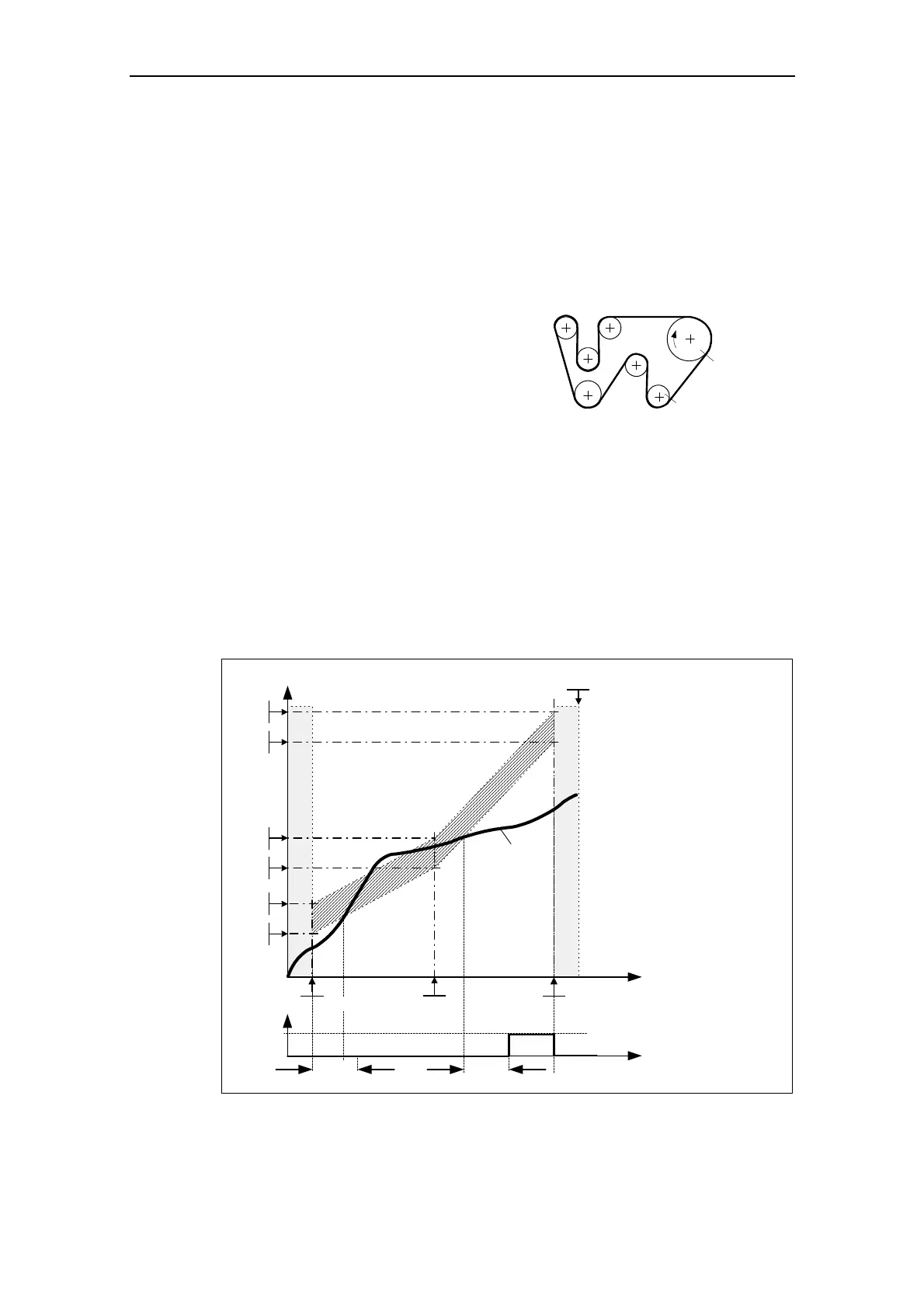

For the load torque monitoring function, the actual frequency/torque characteristic

is compared with the programmed frequency/torque characteristic (refer to P2182 –

P2190). If the actual value lies outside the programmed tolerance bandwidth, then,

depending on parameter P2181, either warning A0952 or fault F0452 is generated.

Parameter P2192 can be used to delay the output of the warning or fault message.

This avoids erroneous alarms which could be caused by brief transient states (refer

to Fig. 3-88).

P2186

P2185

P2188

P2187

P2190

P2189

P2183

P2184

Torque [Nm]

Frequency

[Hz]

P1082

0

1

r2198

Bit 11

t

P2192 P2192

A0952

Actual

torque

P2182

Fig. 3-88 Load torque monitoring (P2181 = 1)

Drive

shaft

Deflection

roll

Fig. 3-87 Shaft drive with flat belts

Loading...

Loading...