3 Functions Issue 10/06

MICROMASTER 440 Operating Instructions

68 6SE6400-5AW00-0BP0

3.1.4 Reference quantities

Parameter range: P2000 – r2004

Physical quantities are normalized or de-normalized by the frequency inverter

when data is output or is being entered. This conversion is undertaken by the

particular interface using the reference quantities. The normalization / de-

normalization is carried-out for the following interfaces:

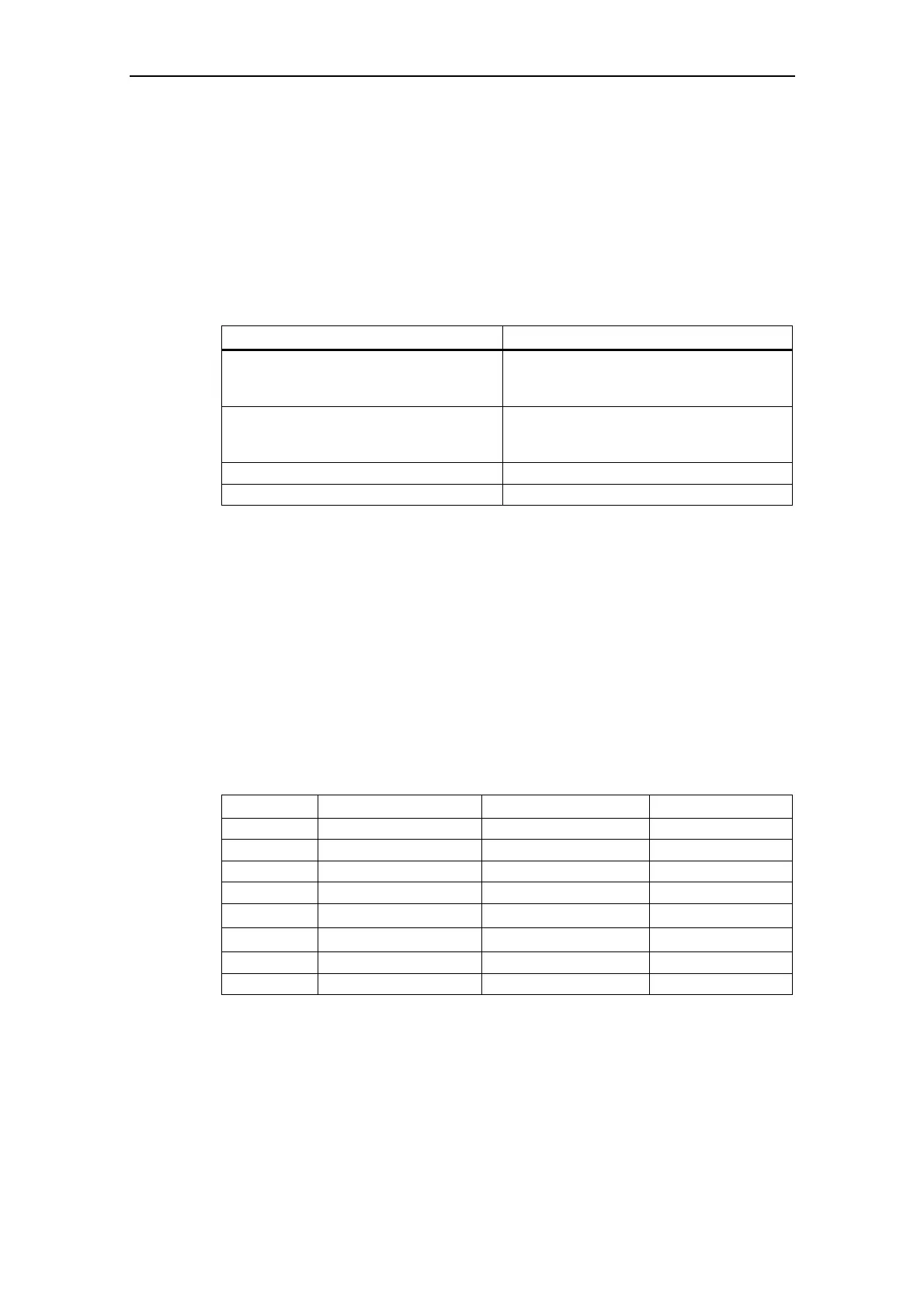

Table 3-5 Normalized interfaces

Interafce 100 %

Analog input

Current input

Voltage input

20 mA

10 V

Analog output

Current output

Voltage output

20 mA

10 V

USS 4000 h

CB 4000 h

Further, for a BICO connection, a normalization is carried-out if the connector

output (CO) represents a physical quantity and the connector input (CI) a

normalized (percentage) quantity (e.g. PID controller). De-normalization is carried-

out if the inverse situation exists. This normalization / de-normalization should be

carefully taken into consideration, especially for the free function blocks (FFBs).

Reference quantities (normalization quantities) are intended to allow setpoint and

actual value signals to be represented in a standard fashion (normalization / de-

normalization of physical quantities such as setpoint and actual frequency). This

also applies for permanently set parameters that are entered as a "percentage". A

value of 100 % corresponds to a process data value PZD of 4000 h (USS or CB) –

or a current / voltage value of 20 mA / 10 V (analog input / output). The following

reference parameters and permanently saved reference values are available:

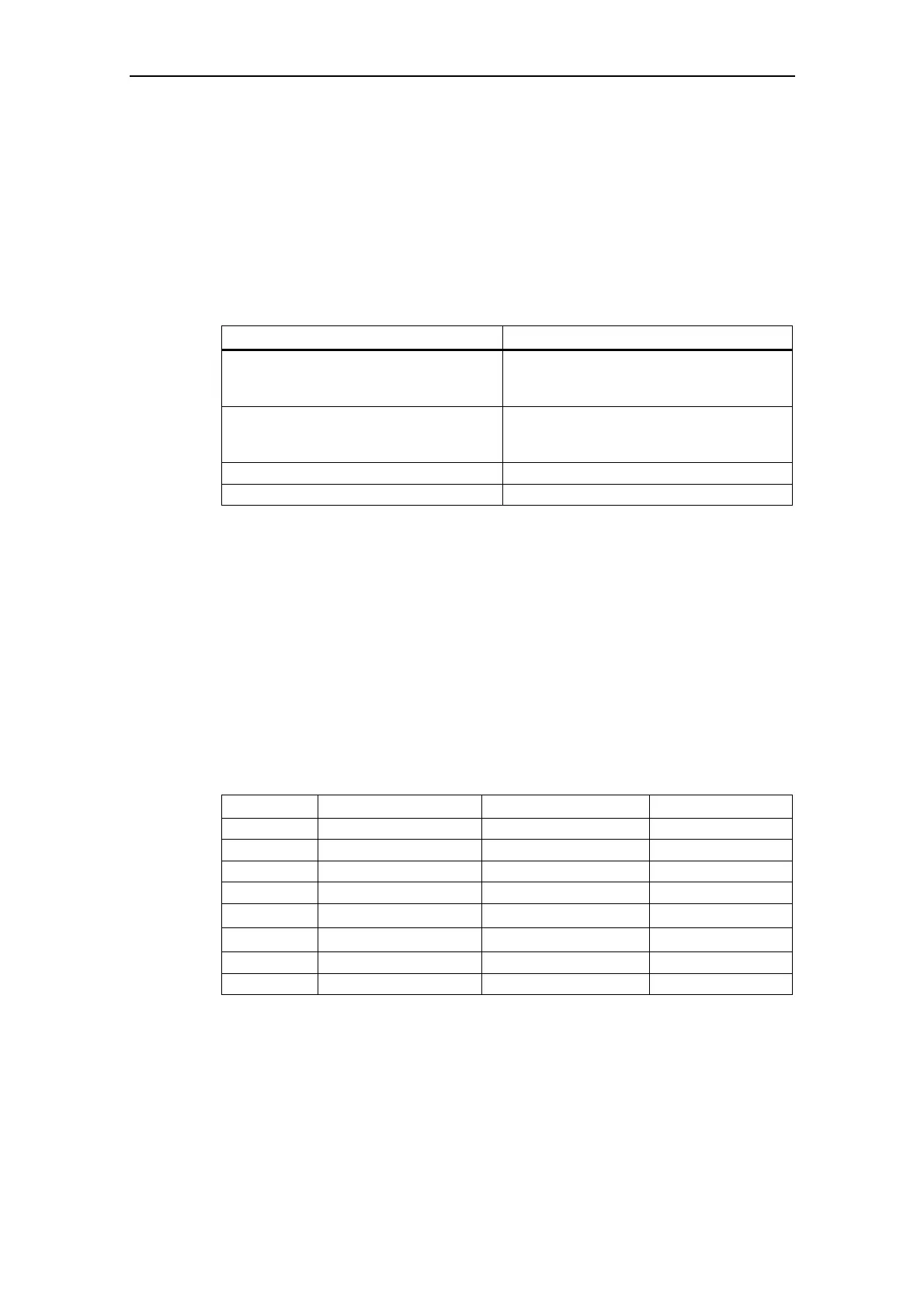

Table 3-6 Normalization functions

Parameter Designation Value (100 % / 4000 h) Units

P2000 Reference frequency P2000 Hz

P2001 Reference voltage P2001 V

P2002 Reference current P2002 A

P2003 Reference torque P2003 Nm

r2004 Reference power

π

*

P2000

*

P2003

kW

- Reference speed

P2000

*

60 / r0313

RPM

- Reference temperature 100 °C °C

- Reference energy 100 kWh kWh

Loading...

Loading...