Issue 10/06 3 Functions

MICROMASTER 440 Operating Instructions

6SE6400-5AW00-0BP0

155

NOTE

If a higher baud rate or higher number of nodes is required, then the CB option

boards (e.g. PROFIBUS, CAN) should be used to ensure disturbance-free

operation.

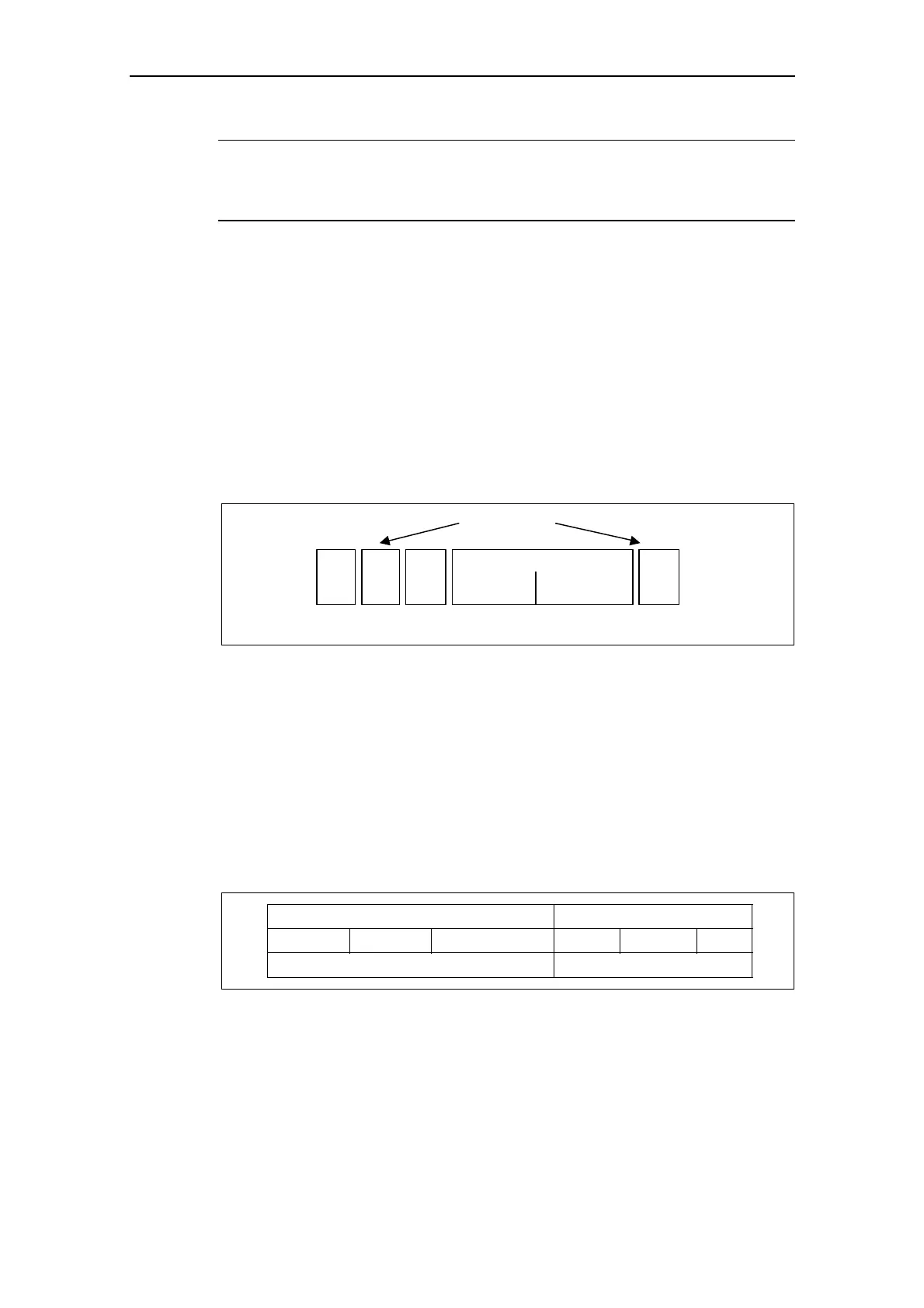

3.7.1.2 The structure of net data

Information which, for example, a SIMATIC S7 control unit (= master) sends to a

drive (= slave) or the drive sends to the control unit is placed in the net-data area of

each telegram.

General structure of the net-data block

The net-data block is divided into two areas:

¾ the PKW (parameter ID value) range

¾ the PZD (process data) range

The structure of the net data in the USS-protocol telegram is shown below.

Protocol frame

Parameter ID value

(parameter area)

STX LGE ADR

(PKW) (PZD)

BCC

PKW: PZD:

Process data

(process-data area)

Process dataParameter

Net data

Fig. 3-45 Telegram structure

¾ The PKW area relates to the handling of the parameter ID value (PKW)

interface. The PKW interface is not a physical interface but a mechanism which

handles parameter transfer between two communication partners (e.g. control

unit and drive). This involves, for example, reading and writing parameter

values and reading parameter descriptions and associated texts.

All tasks which are performed via the PKW interface essentially involve operator

control and visualization, service and diagnosis.

¾ The PZD area contains the signals required for the automation system:

♦ Control word(s) and setpoint(s) from the master to the slave

♦ Status word(s) and actual value(s) from the slave to the master.

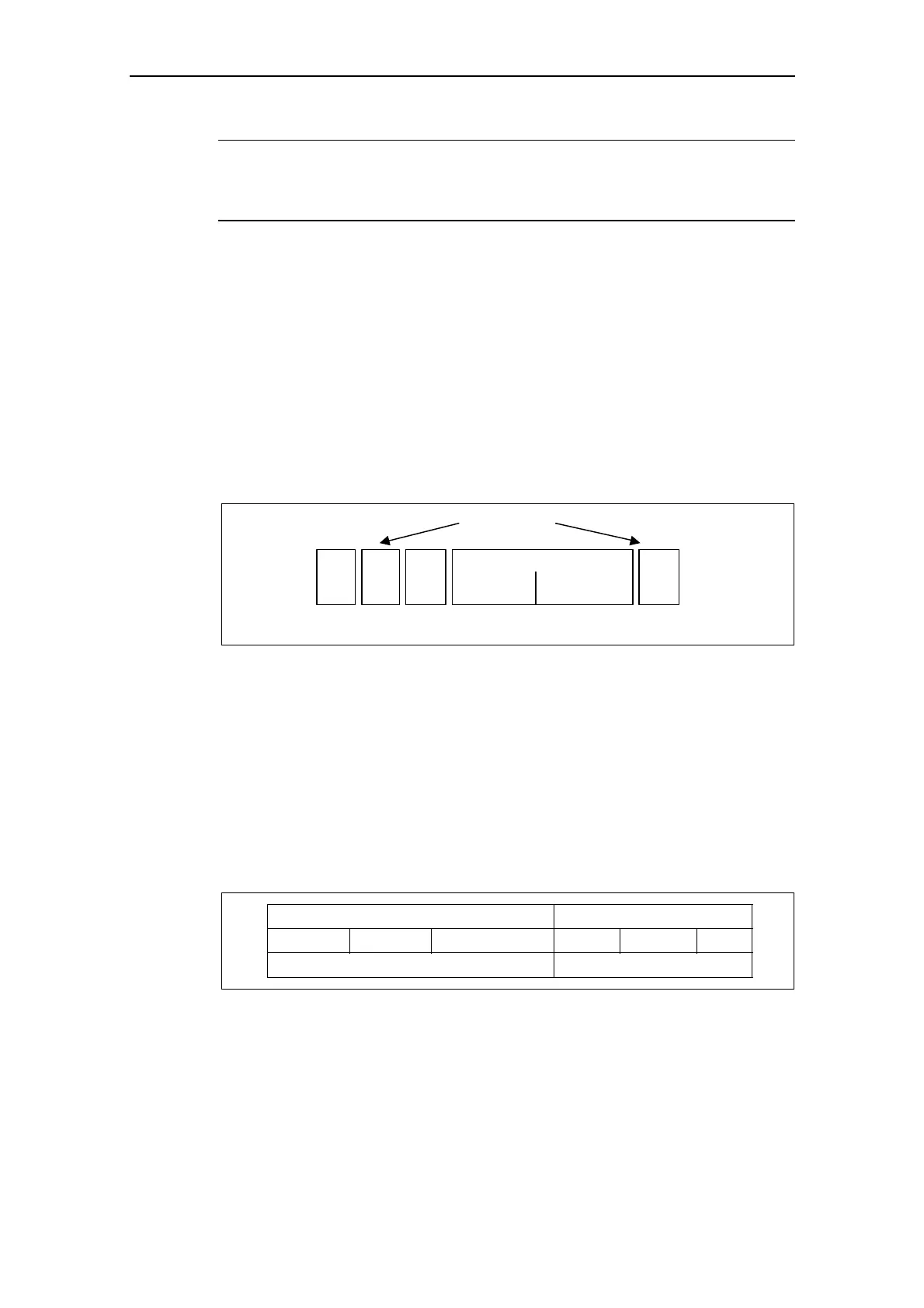

PKW area

PKE IND PZD1 • • • PZD16

PZD area

PKW elements

variable length variable length

Fig. 3-46 Structure of the PKW and PZD areas

The two areas together make up the net data block. This structure applies to

telegrams from the master to the slave and vice versa.

Loading...

Loading...