3 Functions Issue 10/06

MICROMASTER 440 Operating Instructions

248 6SE6400-5AW00-0BP0

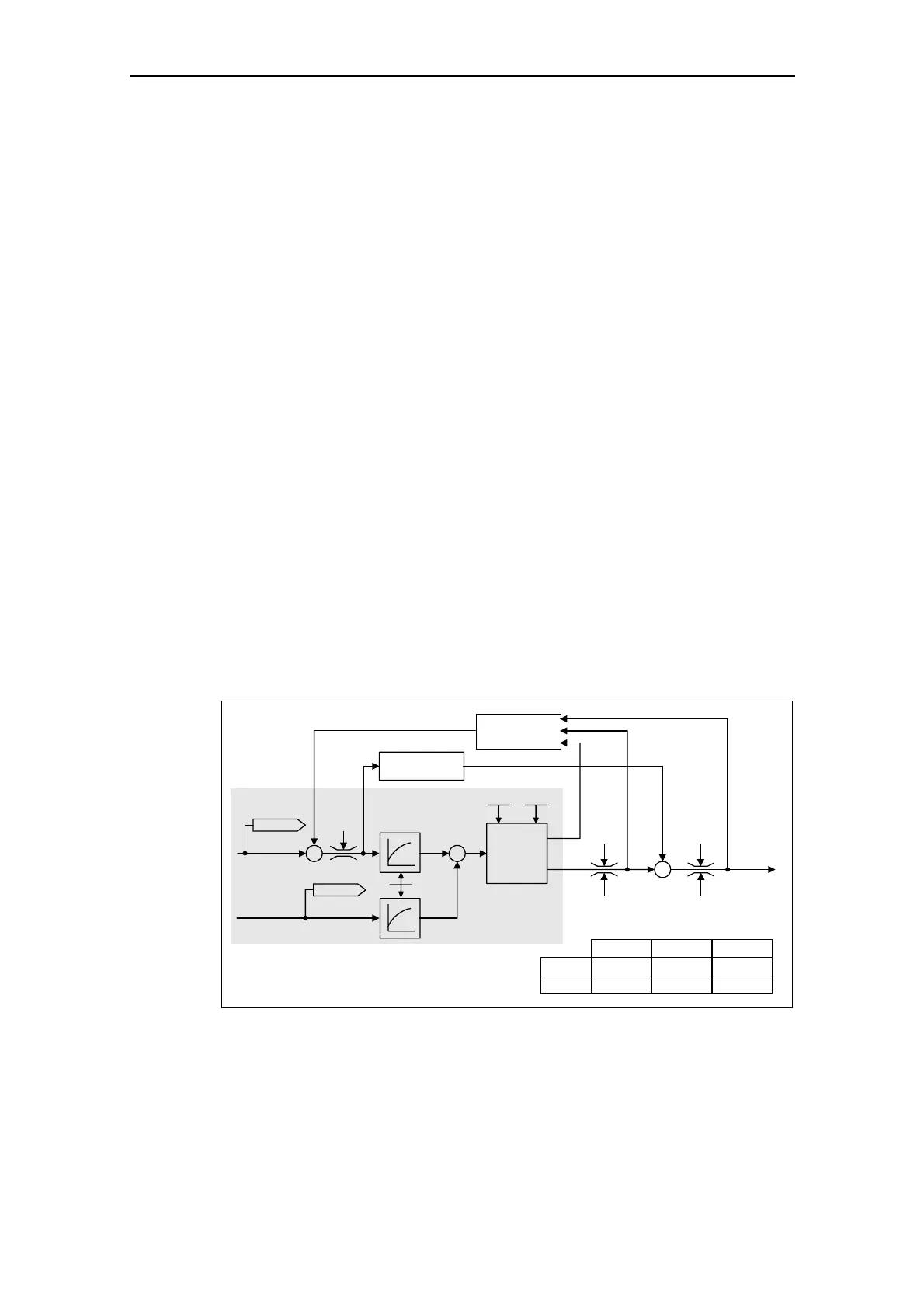

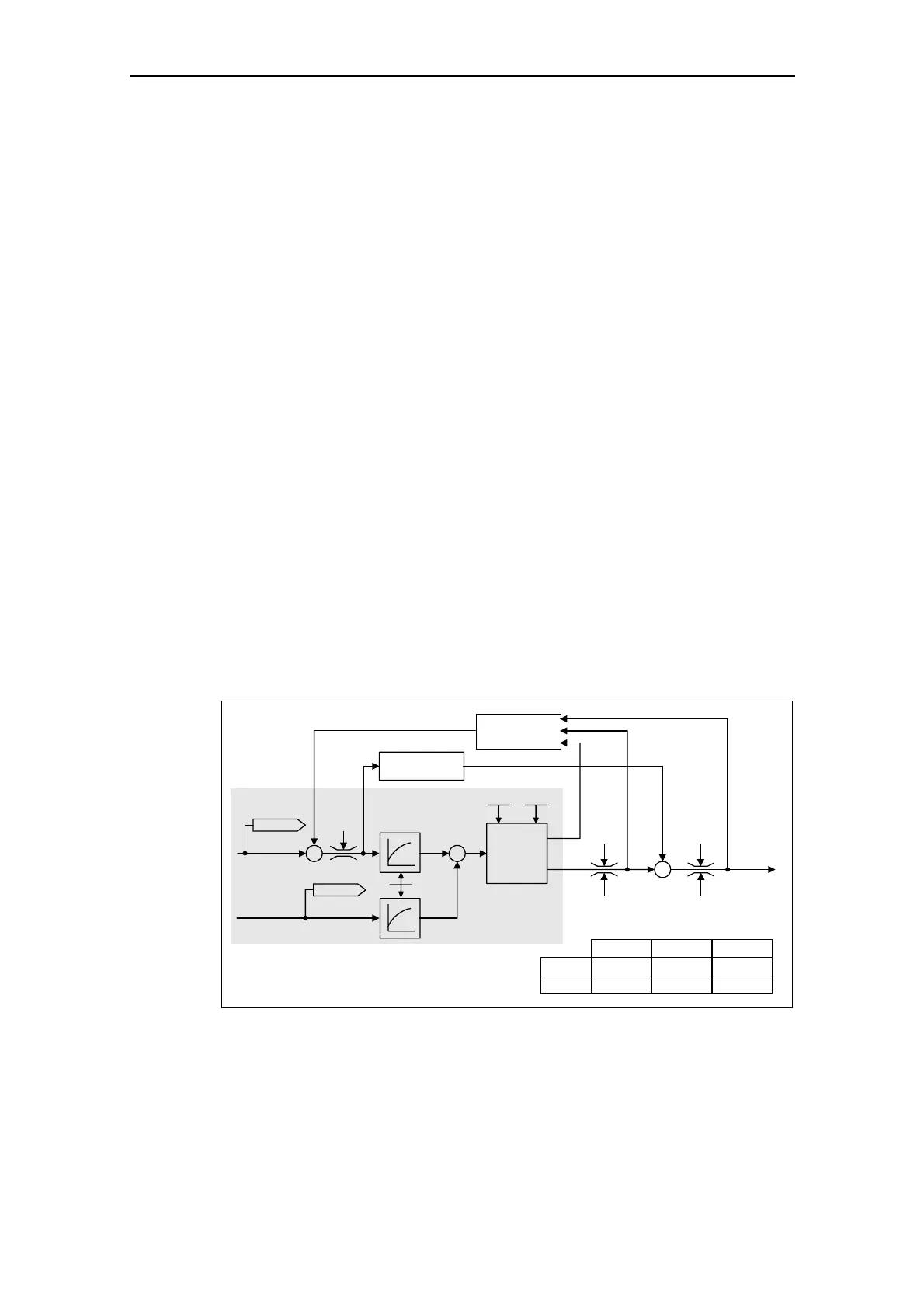

3.23.2.3 Speed controller

Parameter range: P1300, P1400 – P1780

SLVC: P1470, P1472, P1452

VC: P1460, P1462, P1442

Warnings -

Faults -

Function chart number: FP7500, FP7510

Both of the control techniques (SLVC, VC) have the same speed controller

structure which includes the following components as kernel:

¾ PI controller

¾ Speed controller pre-control

¾ Droop

The sum of the output quantities forms the speed setpoint, which is reduced to the

permissible level using the torque setpoint limiting function (refer to Section

3.23.2.4).

Speed controller (SLVC: P1470, P1472, P1452 VC: P1460, P1462, P1442)

The speed controller (refer to Fig. 3-105) receives its setpoint r0062 from the

setpoint channel (refer to Section 3.12), the actual value r0063 either directly from

the speed actual value encoder or, for VC, also directly through the motor model

for SLVC. The system error is amplified by the PI controller and, together with the

pre-control, forms the torque setpoint.

For increasing load torques, when the droop function is active, the speed setpoint

is proportionally reduced so that the load on an individual drive within a group

(where two or several motors are mechanically coupled) is reduced when

excessively high torques occur.

–

Torque

setpoint

Droop

Act. frequency

–

r1538 r1538

r1539 r1539

Pre-

control

Freq. setpoint

PI

Speed

controller

SLVC:

VC:

P1452

P1442

P1470

P1460

P1472

P1462

T

i

K

p

T

n

T

i

K

p

T

n

r1084

r0063

r0062

Speed control

*)

*) only active if pre-control is activated

(P1496 > 0)

Fig. 3-105 Speed controller

Loading...

Loading...