Issue 10/06 3 Functions

MICROMASTER 440 Operating Instructions

6SE6400-5AW00-0BP0

247

3.23.2.2 Vector control with speed encoder (VC)

Parameter range: P1400 – P1740

P0400 – P0494

Warnings -

Faults -

Function chart number: FP7000

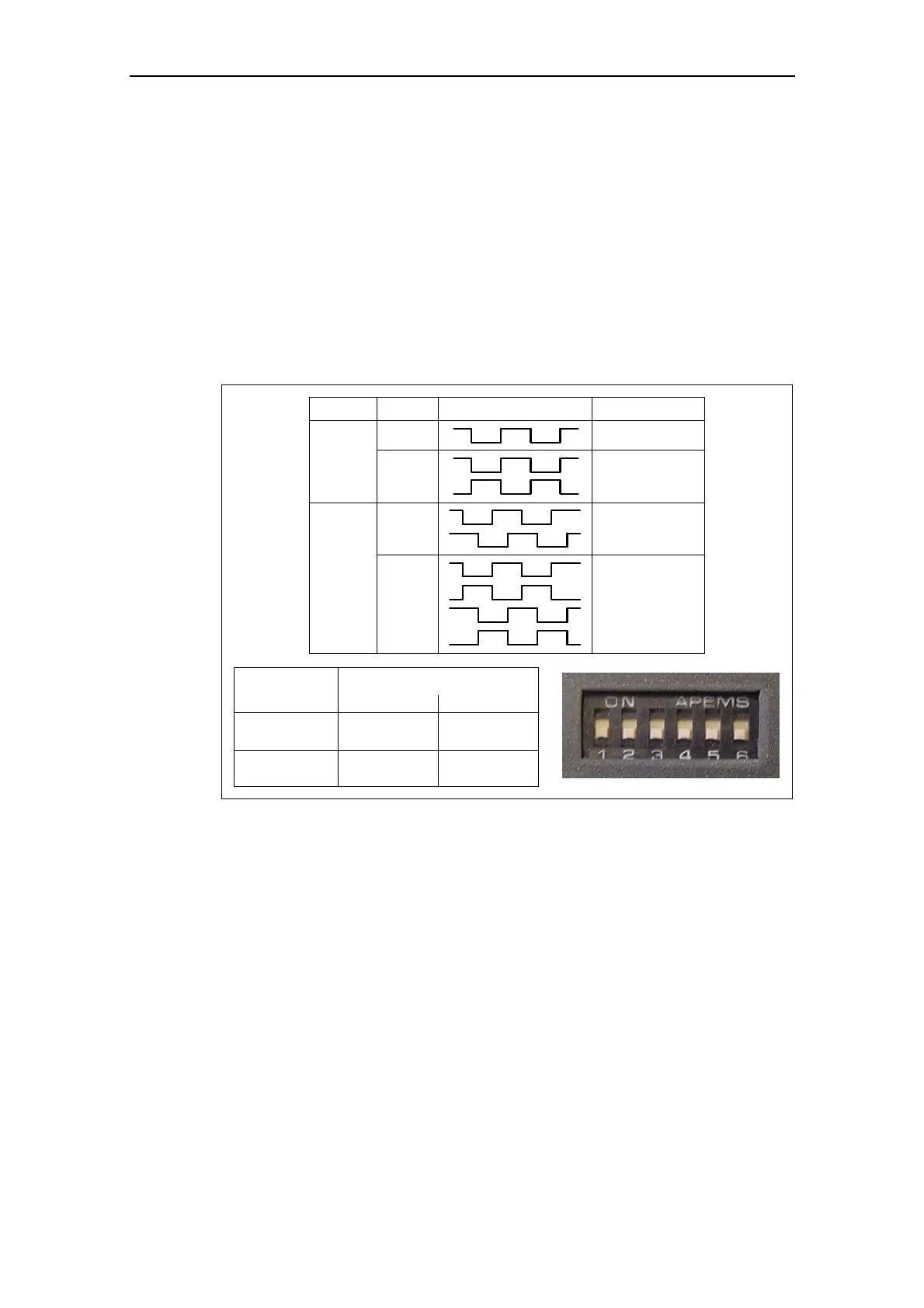

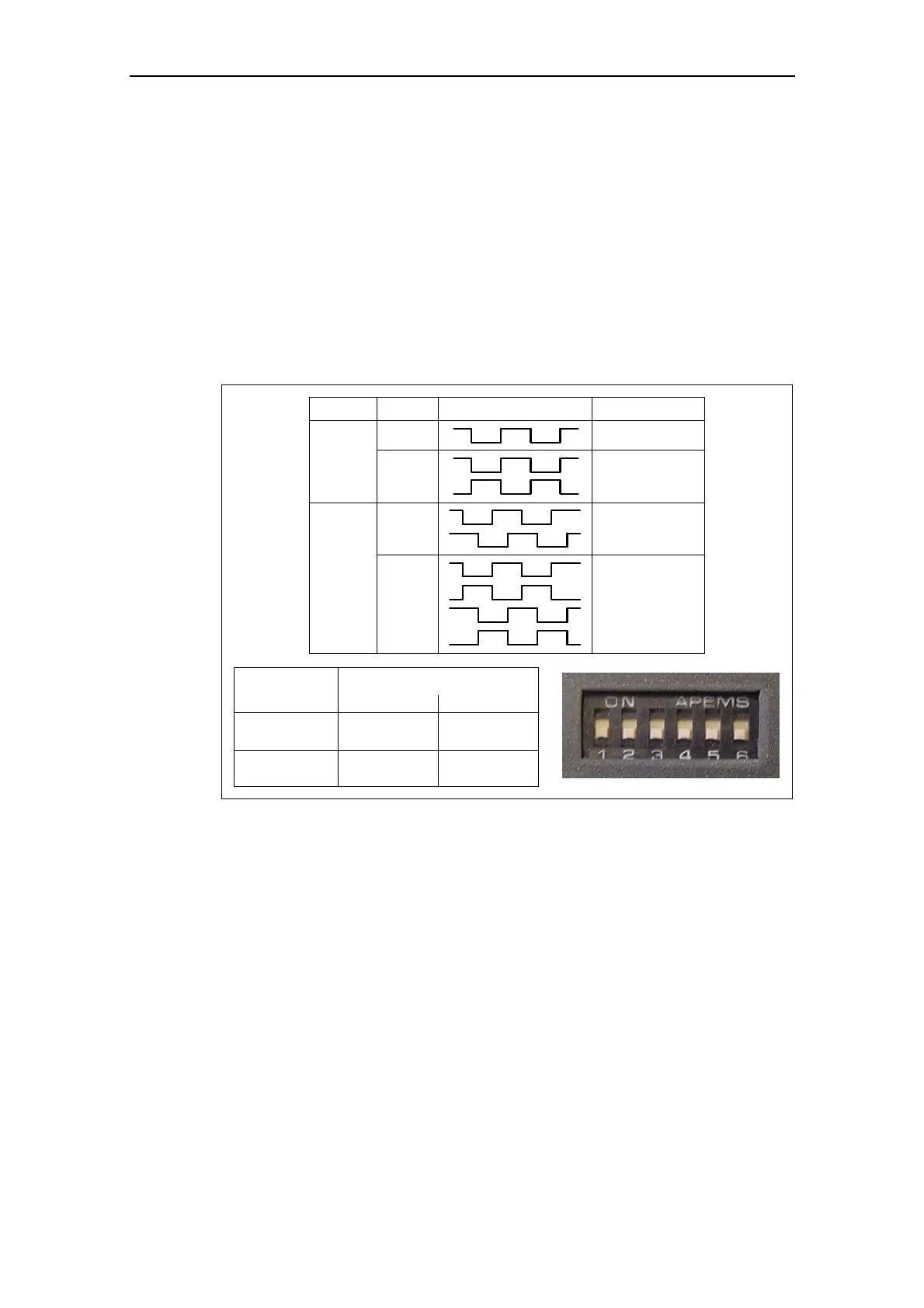

For Vector control with speed encoder (refer to Table 3-40), a pulse encoder

evaluation (option module) as well as a pulse encoder, e.g. encoder with 1024

pulses/revolution are required. In addition to the correct wiring, the pulse encoder

module must be activated, corresponding to the encoder type, using the parameter

range P0400 – P0494 or using the DIP switch on the module (refer to Fig. 3-104).

Parameter

Terminal Track Encoder output

single ended

P0400 = 1 A

differential

A

AN

A

B

A

AN

B

BN

differential

P0400 = 2

single ended

Output

Type

differential

TTL

(e.g. 1XP8001-2)

HTL

111111 010101

(e.g. 1XP8001-1)

101010 000000

single ended

Fig. 3-104 P0400 and DIP switch on the pulse encoder module

Advantages of Vector control with encoder:

¾ The speed can be closed-loop controlled down to 0 Hz (i.e. at standstill)

¾ Stable control behavior over the complete speed range

¾ Constant torque in the rated speed range

¾ When compared to closed-loop speed control without encoder, the dynamic

response for drives with encoder is significantly higher as the speed is directly

measured and is incorporated in generating the model of current components i

d

,

i

q

.

Loading...

Loading...