Issue 10/06 3 Functions

MICROMASTER 440 Operating Instructions

6SE6400-5AW00-0BP0

179

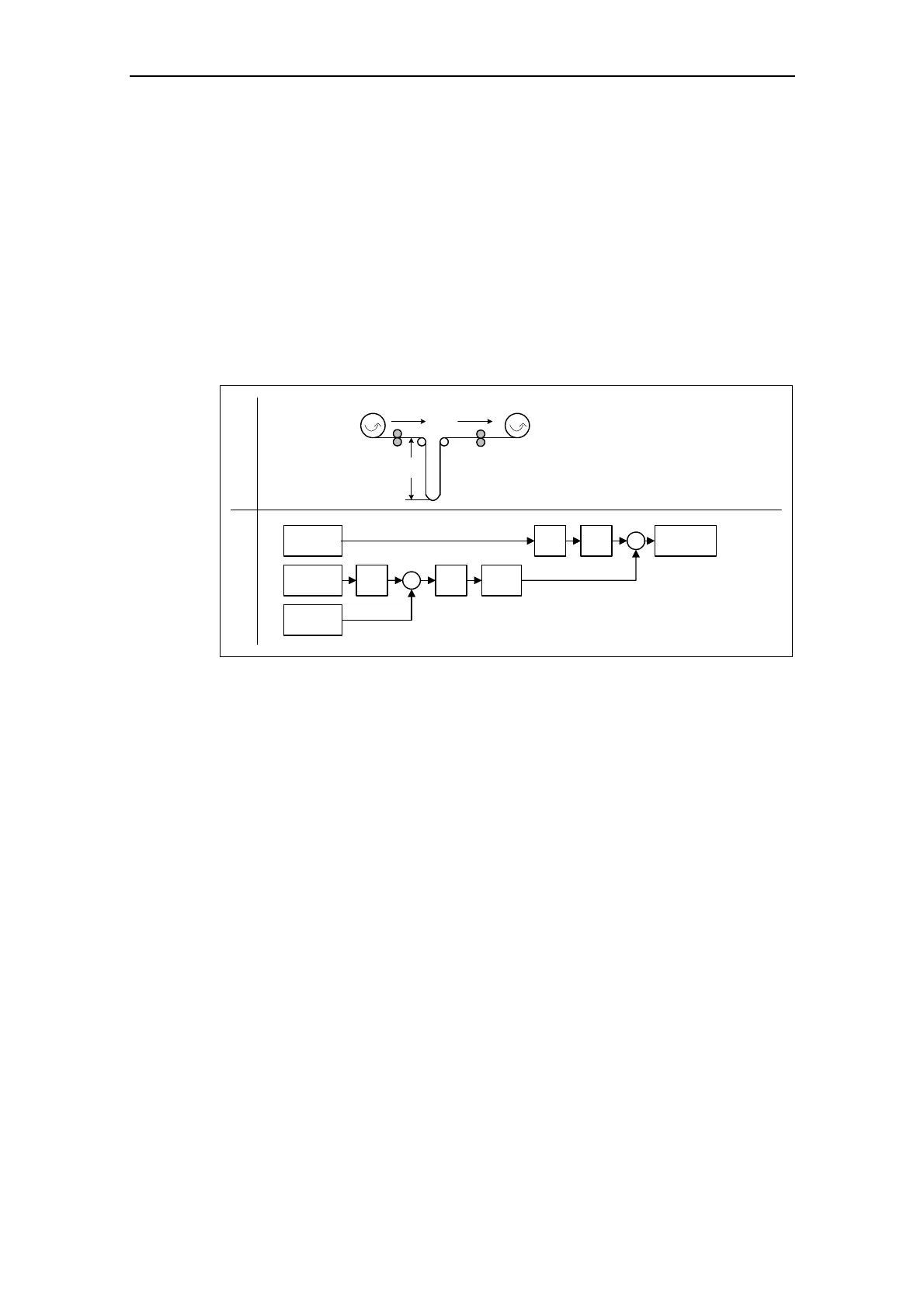

3.11.1.3 PID dancer roll control

For various continuous production processes, e.g. in the paper and pulp industry,

or in the manufacture of cables, it is necessary to control (closed-loop) the velocity

of stations along the production process so that the continuous material web is not

subject to any inadmissible tension levels. It is also important that no folds or

creases are formed. For applications such as these, it is practical to provide a type

of material buffer in the form of a loop with a defined tension. This provides a de-

coupling between the individual drive locations. This loop represents the difference

between the material fed-in and that fed-out and therefore indicates the process

quality.

Using the PID dancer roll control, with MICROMASTER 440 it is possible to ensure

that continuous material webs have a constant tension.

SUM

setpoint

PID

RFG

PID

AFM RFG

x

2

v

2

v

1

v

2

*

x

2

*

x

2

−

PID

setpoint

PID

feedback

PID

limit

Motor

control

Structure Application

Fig. 3-57 PID dancer roll control

The velocity v

1

is assumed to be an independent disturbance; the input velocity v

2

should be controlled using drive rolls A

2

so that the length x

2

of the loop

corresponds, as far as possible, to the setpoint.

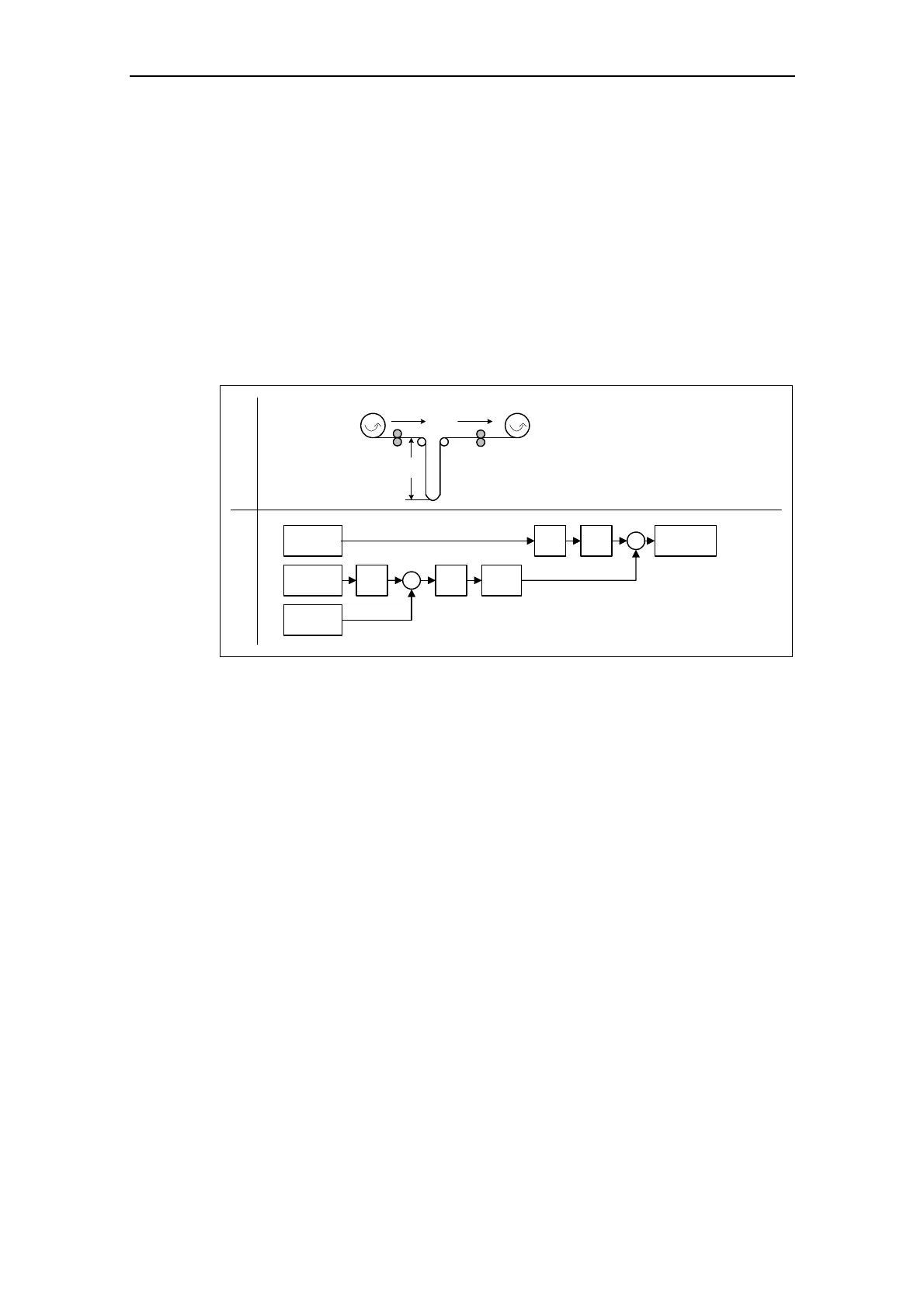

The structure and important parameters for the PID dancer roll control are listed in

Fig. 3-58 and Table 3-27.

Loading...

Loading...