Planning the MOBY D system

4.5 EMC Guidelines

MOBY D

System Manual, 01/2010, J31069-D0147-A6-7618

79

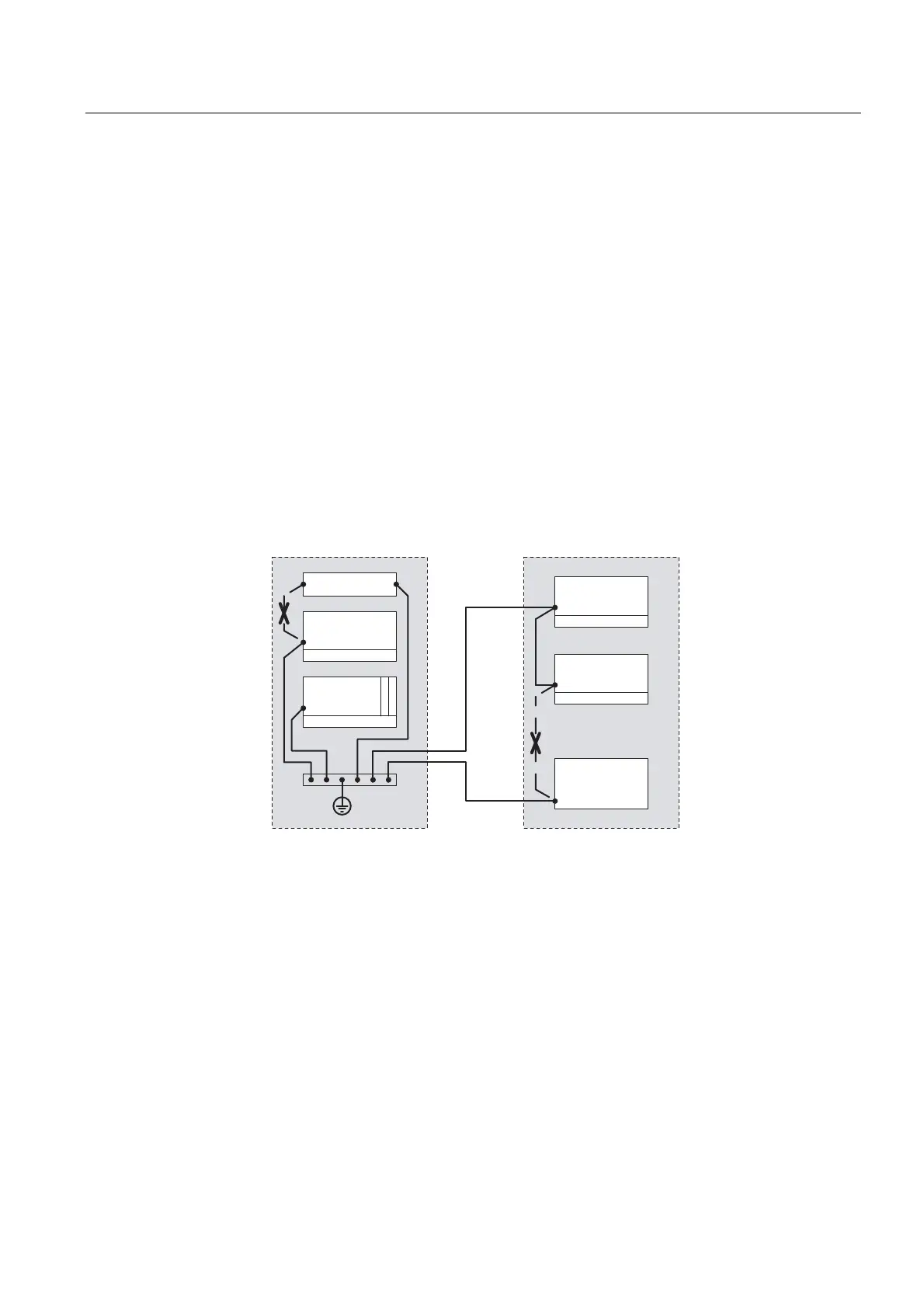

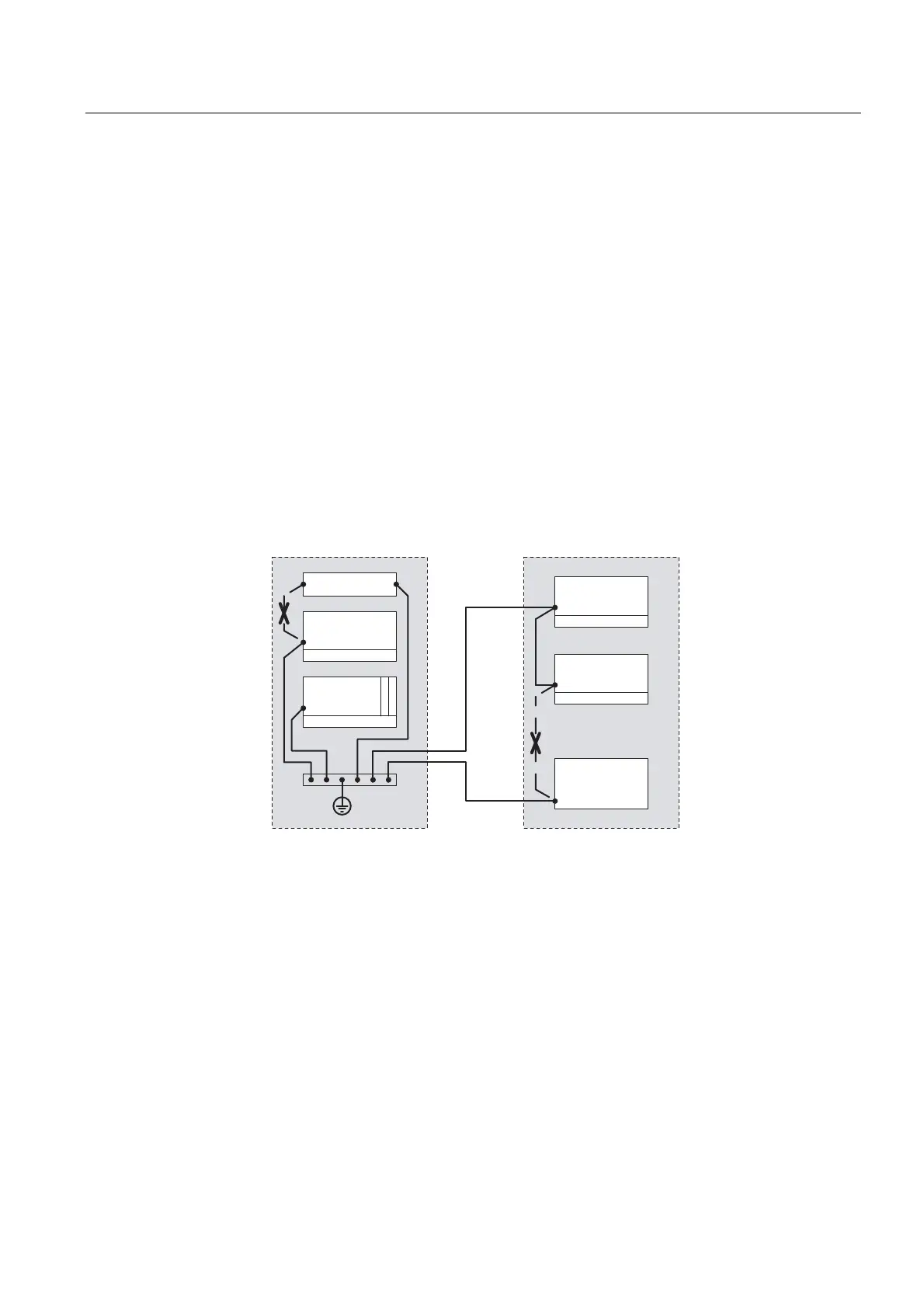

4.5.7 Equipotential bonding

Potential differences between different parts of a plant can arise due to the different design

of the plant components and different voltage levels. If the plant components are connected

across signal cables, transient currents flow across the signal cables. These transient

currents can corrupt the signals.

Proper equipotential bonding is thus essential.

● The equipotential bonding conductor must have a sufficiently large cross section (at least

10 mm

2

).

● The distance between the signal cable and the associated equipotential bonding

conductor must be as small as possible (antenna effect).

● A fine-strand conductor must be used (better high-frequency conductivity).

● When connecting the equipotential bonding conductors to the centralized equipotential

bonding strip (EBS), the power components and non-power components must be

combined.

● The equipotential bonding conductors of the separate modules must lead directly to the

equipotential bonding strip.

&DELQHW &DELQHW

,QFRUUHFW

3RZHUVXSSO\

'ULYH

'HYLFH

3/&

(%6

'HYLFH

'HYLFH

,QFRUUHFW

Figure 4-28 Equipotential bonding (EBS = Equipotential bonding strip)

The better the equipotential bonding in a plant, the smaller the chance of interference due to

fluctuations in potential.

Equipotential bonding should not be confused with protective earthing of a plant. Protective

earthing prevents the occurrence of excessive shock voltages in the event of equipment

faults whereas equipotential bonding prevents the occurrence of differences in potential.

Loading...

Loading...