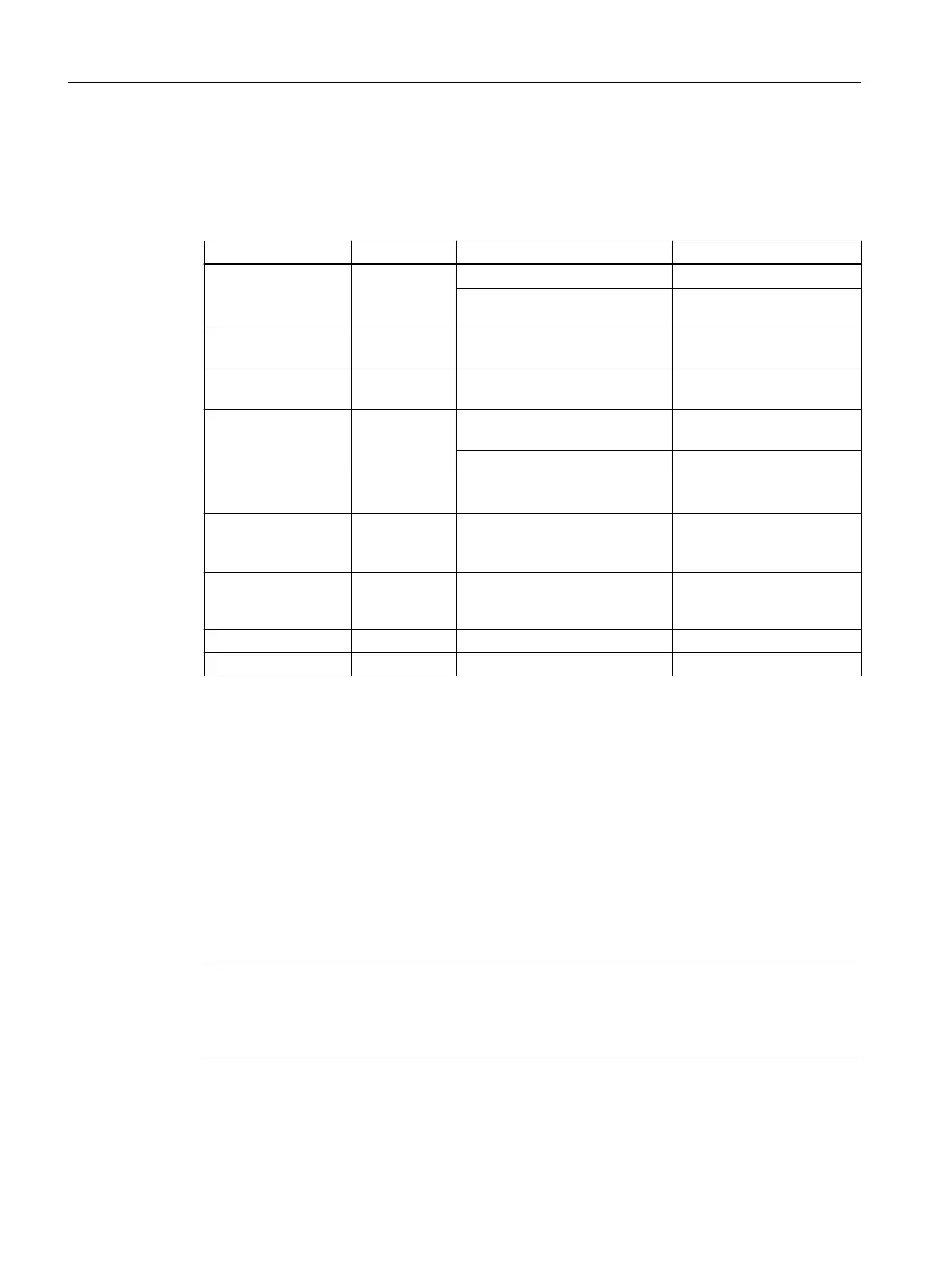

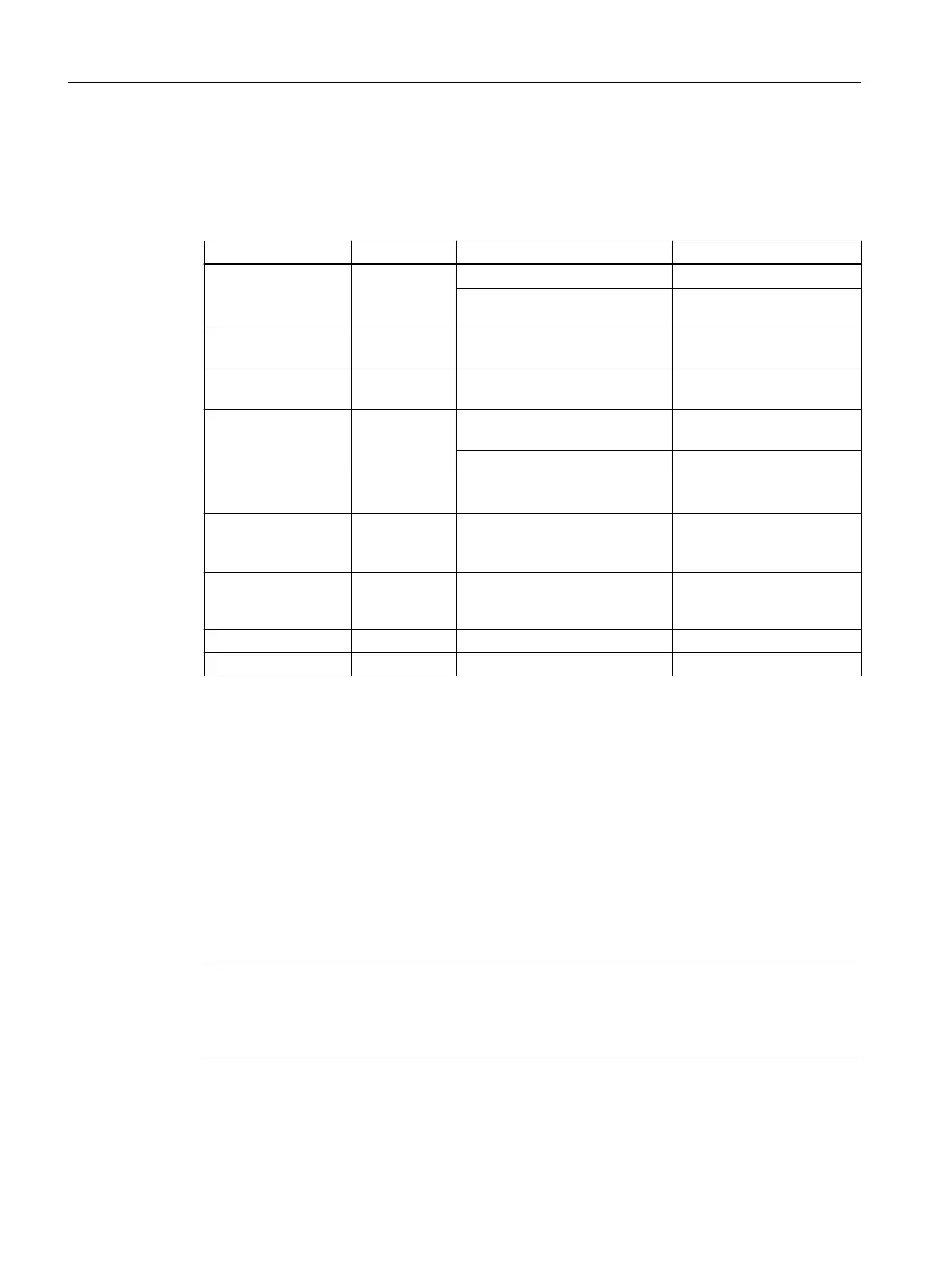

Diagnostic messages and possible corrective measures

The table below provides an overview of the diagnostic messages of the DI 16 x DC 24 V.

Table 10-4 Diagnostic messages of the DI 16 x DC 24 V and possible corrective measures

Diagnostic message Configurable Possible cause of error Corrective measure

No sensor or load

voltage

Yes Overload of sensor supply Eliminate the overload

Short-circuit of sensor supply to

M

Eliminate the short-circuit

Wire break Yes Interruption of the actuator con‐

nection

Check the wiring

No external auxiliary

voltage

No Supply voltage L+ of module

missing

Feed supply L+

Module-internal sup‐

ply voltage

failed

No Supply voltage L+ of module

missing

Feed supply L+

Module-internal fuse defective Replace the module

Module parameters

not assigned

No Startup error Reassign the module pa‐

rameters

Incorrect parameters No One parameter, or the combina‐

tion of parameters, is not plausi‐

ble

Reassign the module pa‐

rameters

Time monitoring trip‐

ped

No Intermittently high electromag‐

netic interference

Eliminate the interference

and switch the ET 200PA

SMART station off and on.

EPROM error No Module defective Replace the module

RAM error No Module defective Replace the module

No sensor or load voltage

When “No sensor supply" diagnostics is activated, failure of the sensor supply is always

signaled for all affected channels.

Reaction to failure of the supply voltage

The input value is initially held for the duration of 20 ms to 40 ms before the "0" signal is

transferred to the CPU. Supply voltage dips < 20 ms do not change the process value.

Failure of the supply voltage with redundant sensor supply infeed

Note

When an external redundant supply is applied to the sensor supply (Vs) and the L+ supply

voltage fails, failure of the sensor supply is not signaled. Instead, a failure of the internal and/or

external auxiliary voltage and/or a blown fuse is signaled.

ET 200PA SMART I/O modules

10.2 Digital input modules

ET 200PA SMART

136 Operating Instructions, 06/2019, A5E34192013-AB

Loading...

Loading...