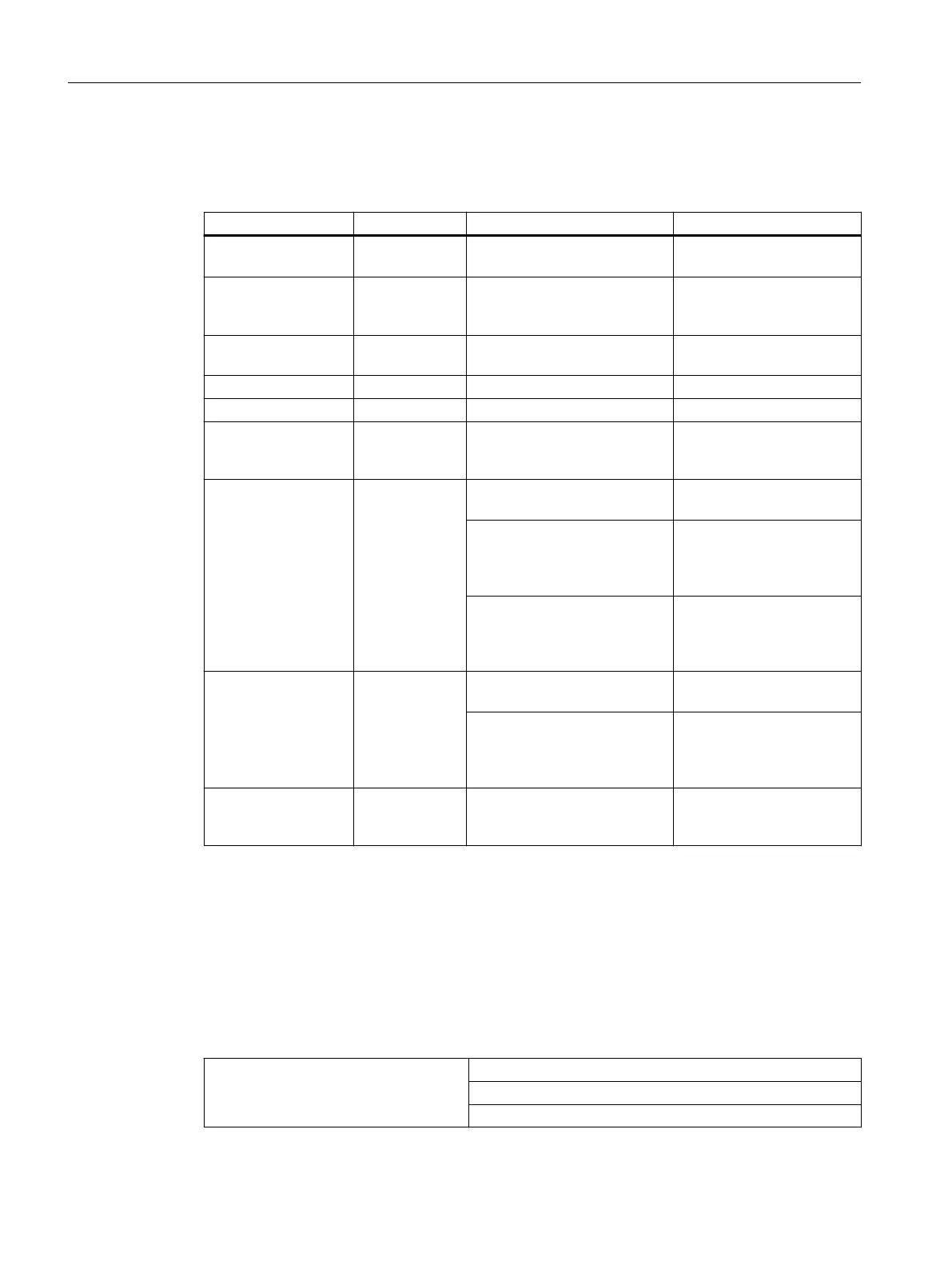

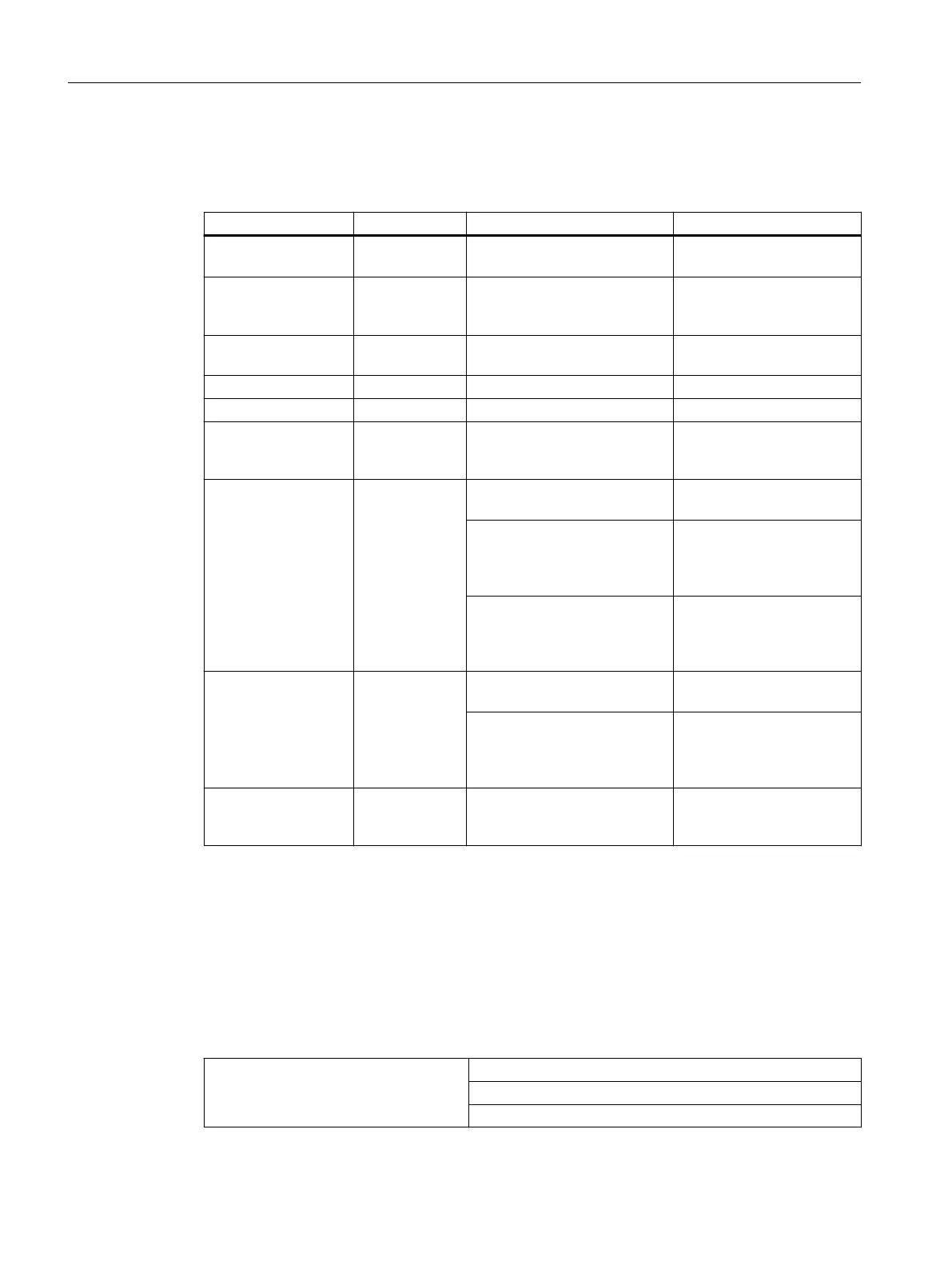

Diagnostic messages and possible corrective measures

Table 10-18 Diagnostic messages of AI 8 x TC/4 x RTD and possible remedial measures

Diagnostic message Configurable Possible cause of error Corrective measure

Module parameters

not assigned

No Startup error Reassign the module pa‐

rameters

Incorrect parameters No One parameter, or the combi‐

nation of parameters, is not

plausible

Reassign the module pa‐

rameters

Time monitoring trip‐

ped

No Intermittently high electromag‐

netic interference

Eliminate the interference

EPROM error No Module defective Replace the module

RAM error No Module defective Replace the module

Parameter assign‐

ment error

No One parameter, or the combi‐

nation of parameters, is not

plausible

Reassign the module pa‐

rameters

Wire break Yes The connection of the trans‐

ducer is interrupted

Check the wiring

Resistance of sensor protec‐

tion circuit too high

Use a different type of sen‐

sor or modify the wiring, for

example, use cables with

larger cross-section

Channel not connected (open) Disable the channel group

("Measurement type" pa‐

rameter) or connect the

channel

Low limit violation of

measuring range / un‐

derrange

Yes

(group diagnos‐

tics)

Analog value below the under‐

range

Check the measuring range

selection

In the case of measuring range

4 mA to 20 mA, sensor may be

connected with reverse polari‐

ty.

Check terminals

High limit violation of

measuring range / un‐

derrange

Yes

(group diagnos‐

tics)

Analog value above the over‐

range

Assign a different measur‐

ing range

10.5 Analog output modules

Overview of properties

The table below presents the ET 200PA SMART analog output module based on its most

important properties.

Properties Module

AO 8 x 12 Bit

6ES7 650-8BK60-xAA0

ET 200PA SMART I/O modules

10.5 Analog output modules

ET 200PA SMART

200 Operating Instructions, 06/2019, A5E34192013-AB

Loading...

Loading...