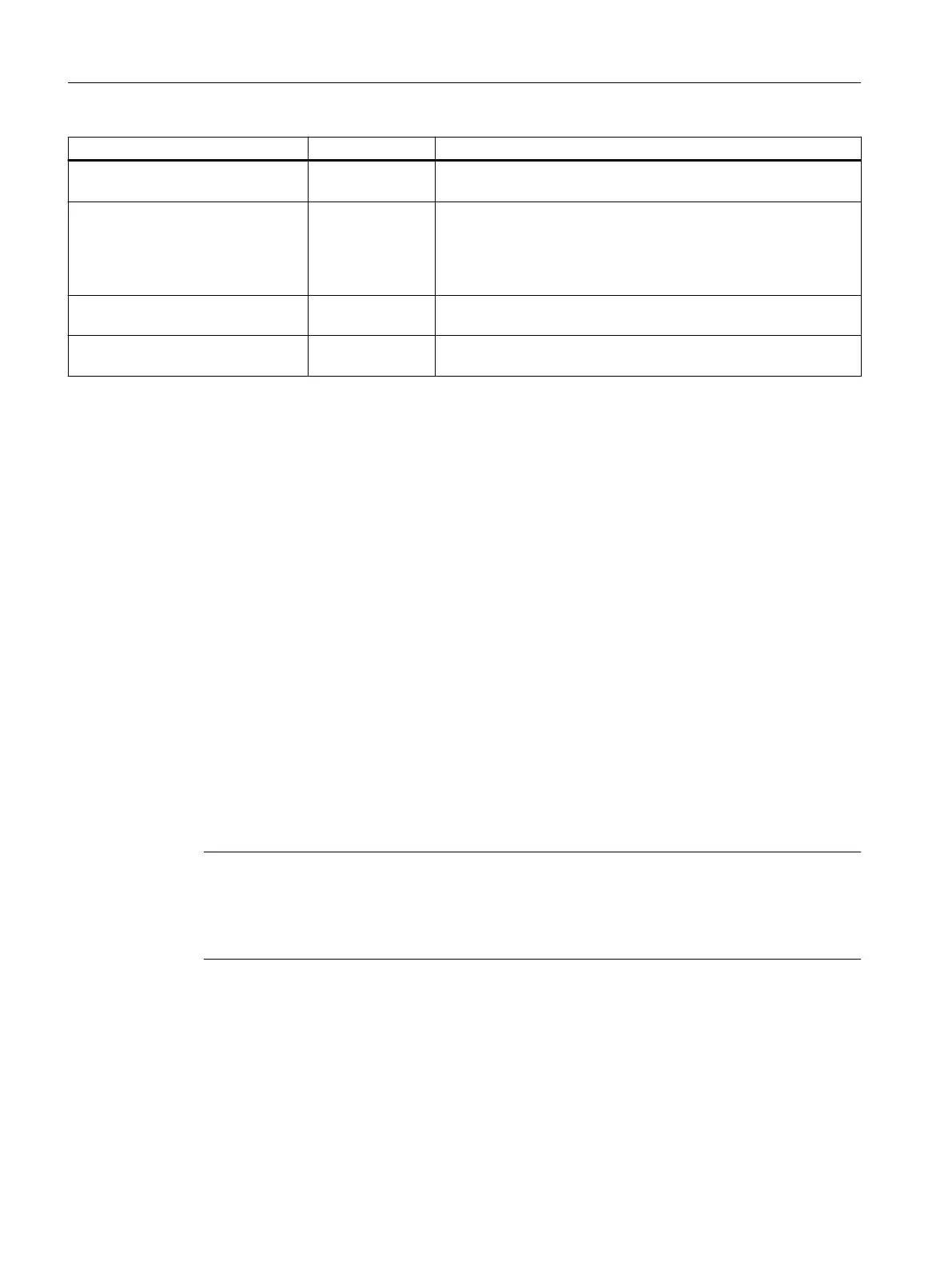

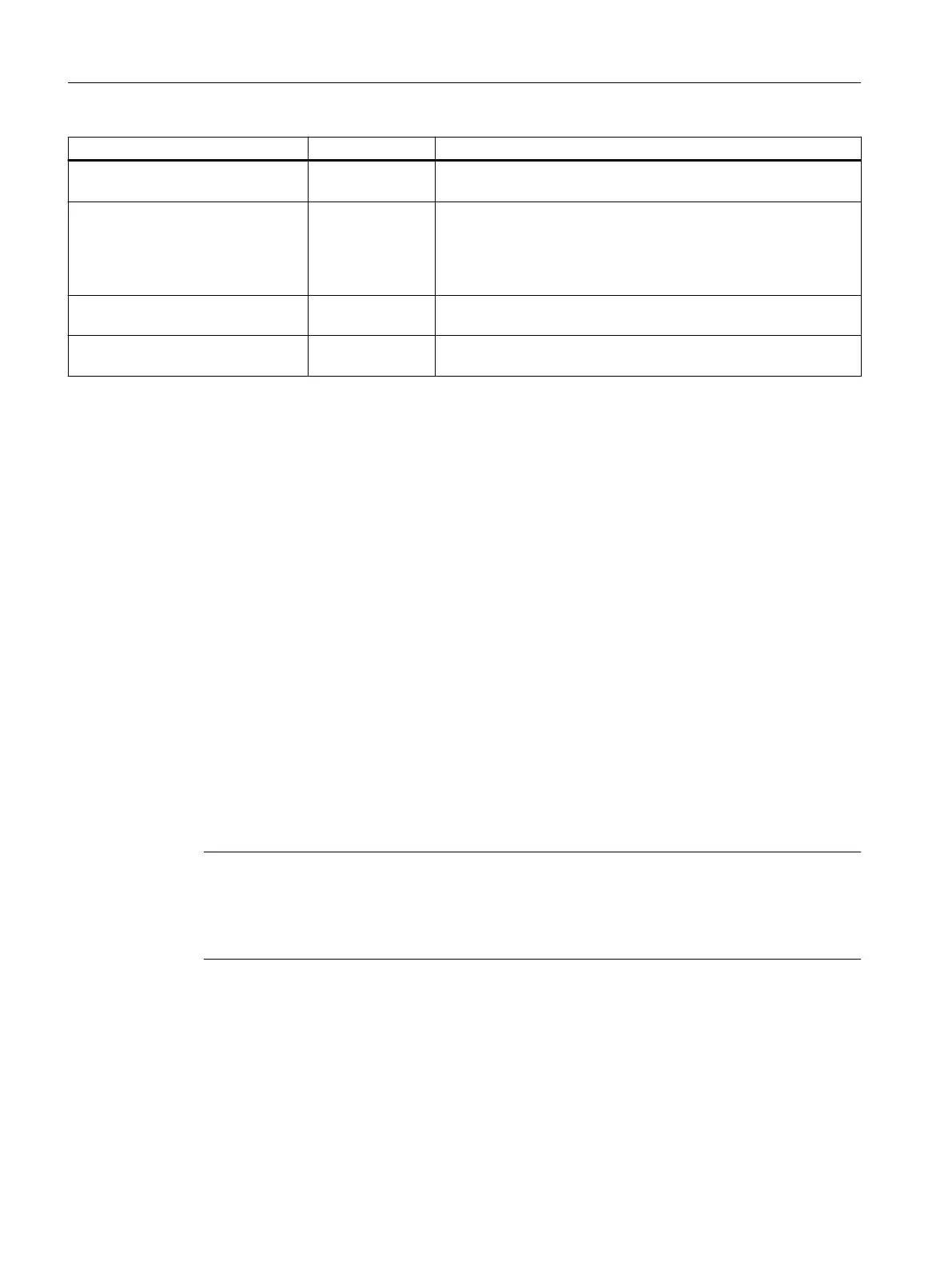

Material Used as Description

PVC Pipes, valves, t‐

tings and hoses

Use is not permitted.

Hoses Reduce the use of hoses to a minimum (device connection). Must

not be used as the main pipe for the whole system. Recommenda‐

tion: EPDM hoses with an electrical resistance>10

9

Ω (e.g. Sem‐

perex FKD supplied from Semperit or DEMITTEL; from PE/EPD,

supplied from Telle).

Gaskets Pipes, valves and

ttings

Use of Viton, AFM34, EPDM is recommended.

Hose connections Transition

Hose-pipe

Secure with clips conforming to DIN 2817, available e.g. from the

Telle company.

The following recommendation applies in order to achieve an optimum motor heatsink

(enclosure) lifetime:

• Engineer a closed cooling circuit with cooling unit manufactured out of stainless steel that

dissipates the heat through a water-water heat exchanger.

• All other components such as cooling circuit cables and ttings manufactured out of ABS,

stainless steel or general construction steel.

Cooling system manufacturers

ait-deutschland GmbH www.kkt-chillers.com

BKW Kälte-Wärme-Versorgungstechnik GmbH www.bkw-kuema.de

DELTATHERM Hirmer GmbH www.deltatherm.de

Glen Dimplex Deutschland GmbH www.riedel-cooling.com

Helmut Schimpke und Team Industriekühlanlagen

GmbH + Co. KG

www.schimpke.org

Hydac System GmbH www.hydac.com

Hyfra Industriekühlanlagen GmbH www.hyfra.de

Pfannenberg GmbH www.pfannenberg.com

Note

Other manufacturers

You can also use equivalent products from other manufacturers.

Responsibility for the properties of third-party products resides with the plant manufacturer.

Consider the following pressure conditions when designing the cooling circuit.

Permissible pressure

• Dene the working pressure based on the ow conditions in the supply and return pipes of

the cooling circuit.

Mechanical properties

4.1Cooling

1PH8 SIMOTICS M main motors

74 Conguration Manual, 12/2022, A5E51895839A

Loading...

Loading...