Programming and Operating Manual (Milling)

6FC5398-4DP10-0BA6, 09/2017

193

_LP1 REAL Length of the approach travel (with straight-line) or radius of the approach arc (with circle)

The following parameters can be selected as options:

_FF3 REAL Retraction feedrate and feedrate for intermediate positions in the plane (in the open)

_AS2 INT Specification of the retraction direction/path: (enter without sign)

UNITS DIGIT:

Values:

1: Straight tangential line

2: Quadrant

3: Semi-circle

TENS DIGIT:

Values:

0: Retraction from the contour in the plane

1: Retraction from the contour in a spatial path

_LP2 REAL Length of the retraction travel (with straight-line) or radius of the retraction arc (with circle)

(enter without sign)

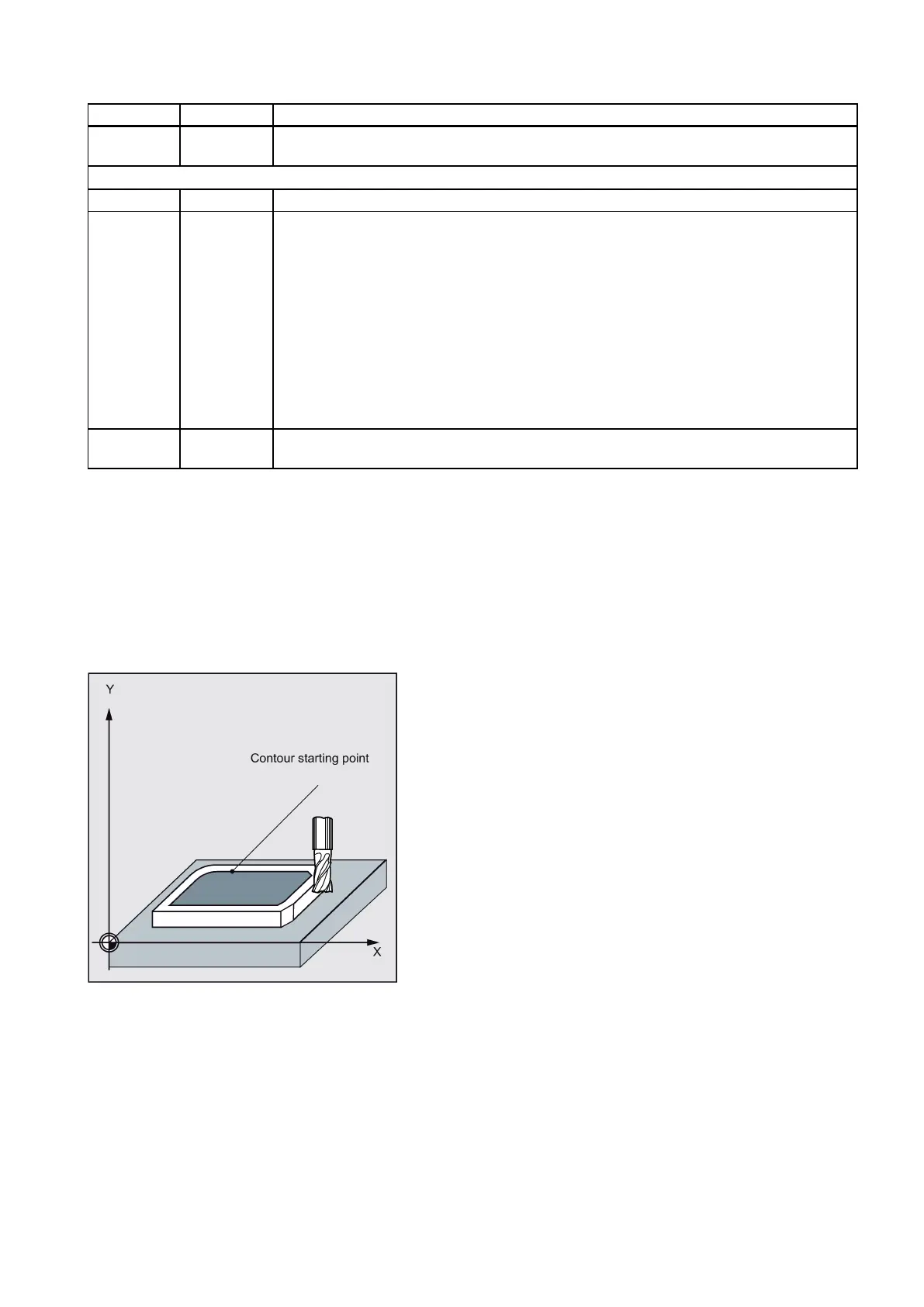

Use CYCLE72 to mill along any contour defined in a subroutine. The cycle operates with or without cutter radius

compensation.

It is not imperative that the contour is closed. Internal or external machining is defined via the position of the cutter radius

compensation (centrally, left or right to the contour).

The contour must be programmed in the direction as it is to be milled and must consist of a minimum of two contour blocks

(start and end point), since the contour subroutine is called directly internally in the cycle.

See the following illustration for path milling 1:

Loading...

Loading...