Programming and Operating Manual (Milling)

232 6FC5398-4DP10-0BA6, 09/2017

Programming example (thread from bottom to top)

A thread with a pitch of 3 mm is to start from -20 and to be milled to 0. The retraction plane is at 8.

N10 G17 X100 Y100 S300 M3 T1 D1 F1000

N30 CYCLE90 (8, -20, 0, -60, 0, 46, 40, 3, 800, 3, 0, 50,

50)

The hole must have a depth of at least -21.5 (half pitch in excess).

Overshooting in the direction of the thread length

For thread milling, the travel-in and travel-out movements occur along all three axes concerned. This means that the travel-

out movement includes a further step in the vertical axis, beyond the programmed thread depth.

The overshoot is calculated as follows:

∆z: Overshoot, internal

p: Pitch

WR: Tool radius

DIATH: External diameter of the thread

RDIFF: Radius difference for travel-out circle

For internal threads, RDIFF = DIATH/2 - WR; for external threads, RDIFF = DIATH/2 + WR.

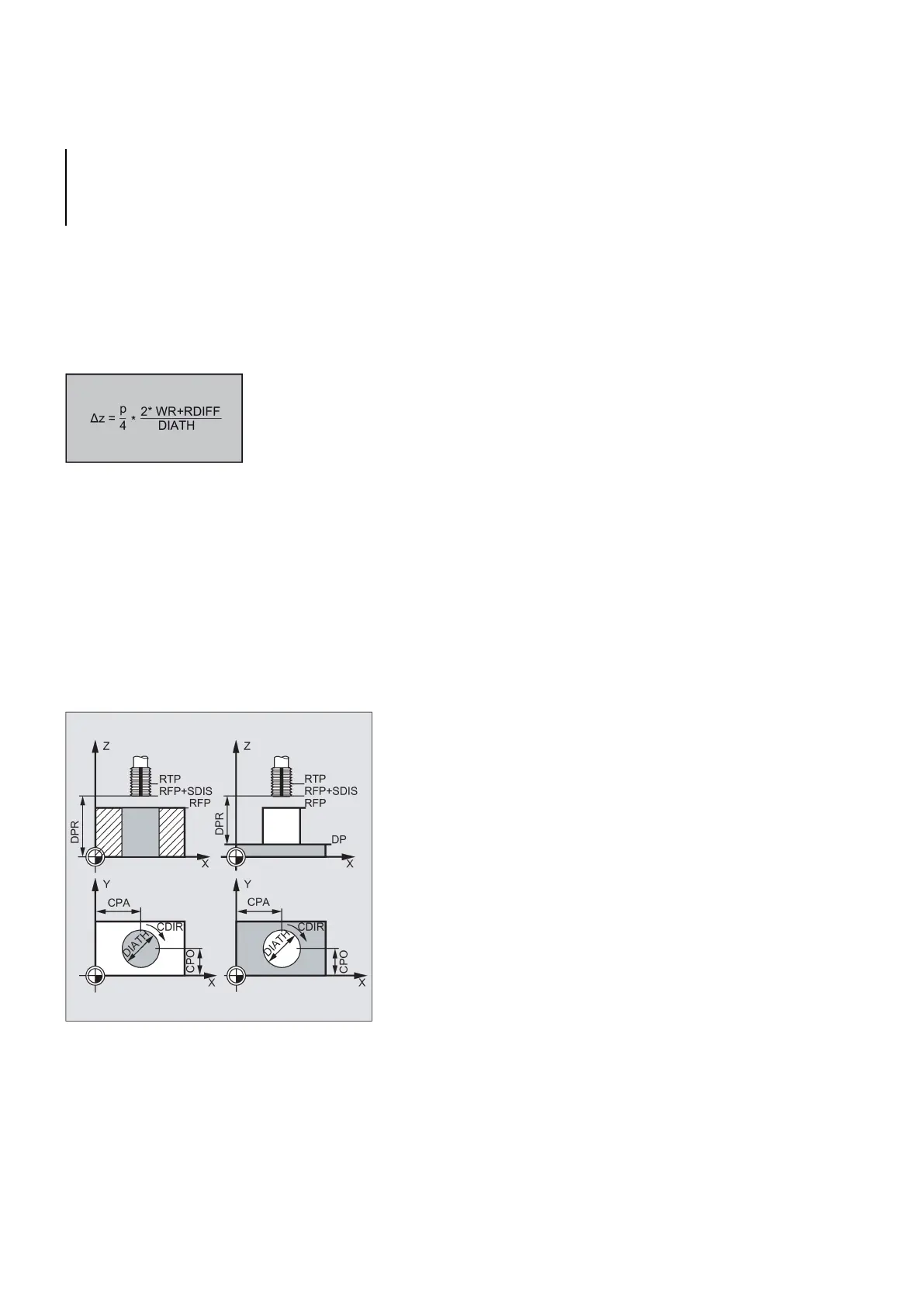

Explanation of the parameters

For an explanation of the parameters RTP, RFP, SDIS, DP, and DPR, see Section "Drilling, centering - CYCLE81

(Page 157) ".

DIATH, KDIAM, and PIT (nominal diameter, core diameter, and thread pitch)

These parameters are used to determine the thread data nominal diameter, core diameter, and pitch. The parameter DIATH

is the external, and KDIAM is the internal diameter of the thread. The travel-in/travel-out movements are created internally in

the cycle, based on these parameters.

Loading...

Loading...