Programming and Operating Manual (Milling)

6FC5398-4DP10-0BA6, 09/2017

233

The value of the parameter FFR is specified as the current feedrate value for thread milling. It is effective when thread

milling on a helical path.

This value will be reduced in the cycle for the travel-in/travel-out movements. The retraction is performed outside the helix

path using G0.

CDIR (direction of rotation)

This parameter is used to specify the value for the machining direction of the thread.

If the parameter has an illegal value, the following message will appear:

"Wrong milling direction; G3 is generated".

In this case, the cycle is continued and G3 is automatically generated.

The parameter TYPTH is used to define whether you want to machine an external or an internal thread.

CPA and CPO (center point)

These parameters are used to define the center point of the drill hole or of the spigot on which the thread will be produced.

The cutter radius is calculated internally in the cycle. Therefore, a tool

compensation must be programmed before calling the

cycle. Otherwise, the alarm 61000 "No tool compensation active" appears and the cycle is aborted.

If the tool radius=0 or negative, the cycle is also aborted and this alarm is issued.

With internal threads, the tool radius is monitored and alarm 61105 "Cutter radius too large" is output, and the cycle is

aborted.

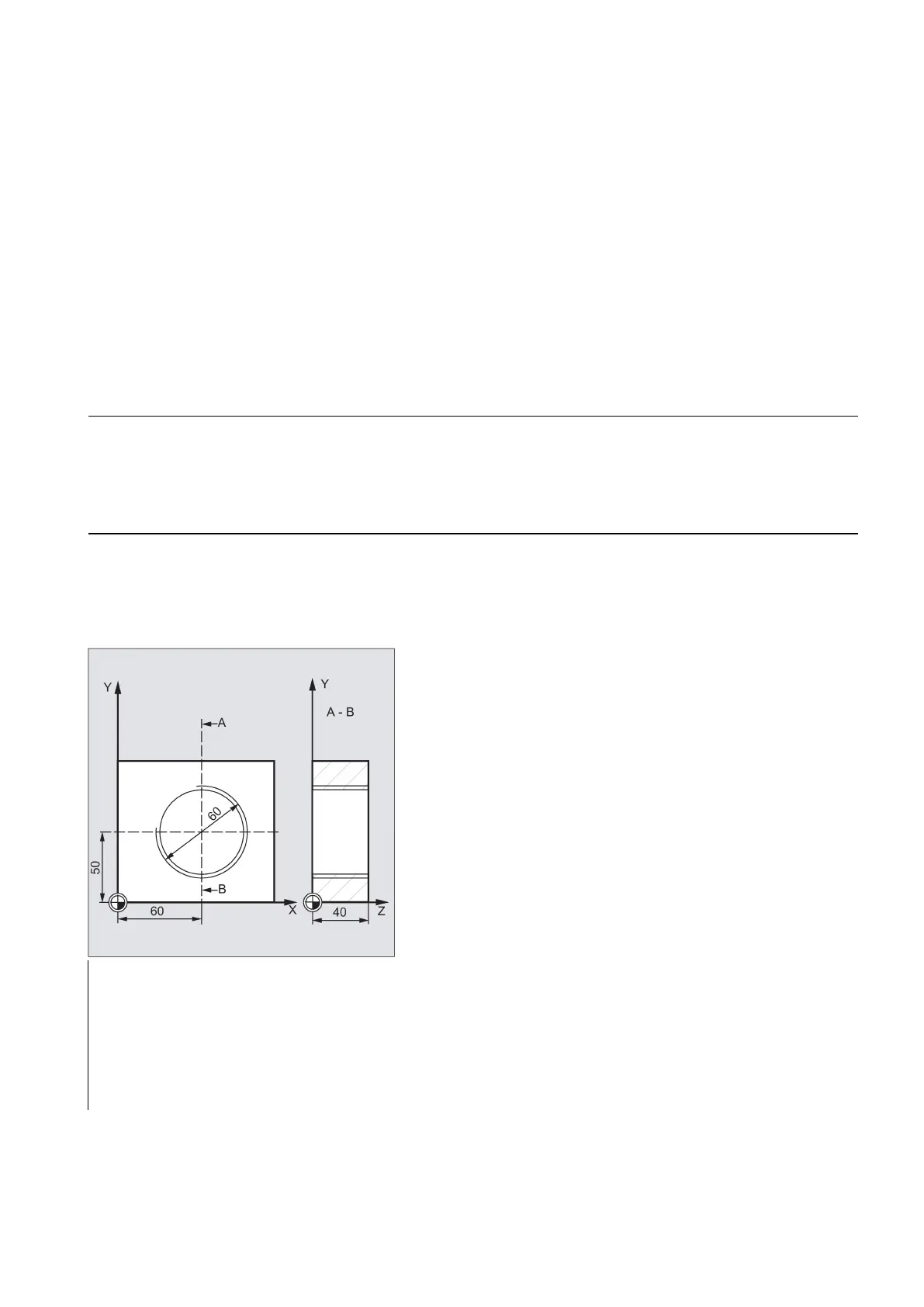

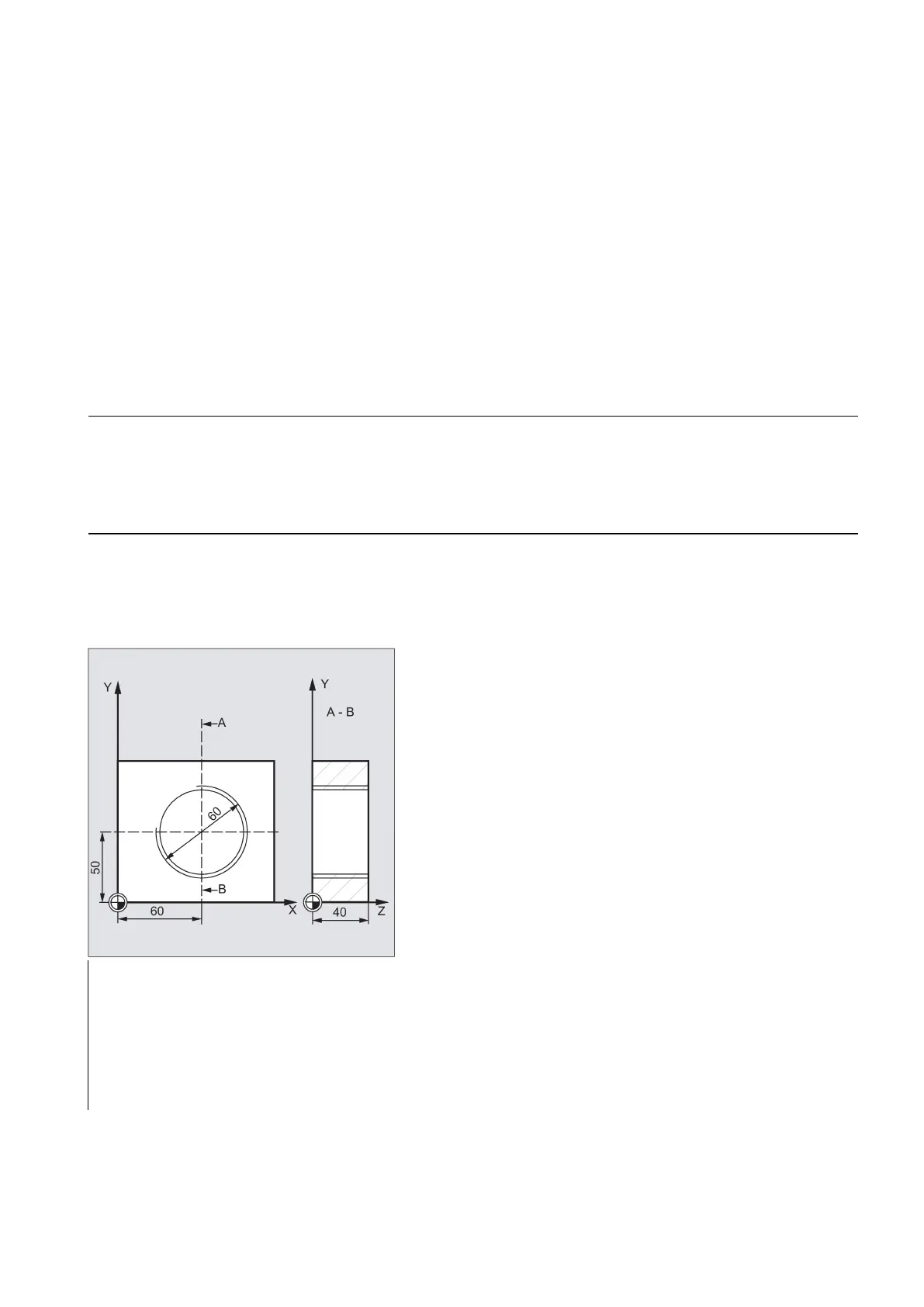

Programming example: Internal thread

By using this program, you can mill an internal thread at point X60 Y50 of the G17 plane.

See the following programming example for internal thread:

DEF REAL RTP=48, R FP=40, SDIS=5, DP=0, DPR=40, DIATH=60,

KDIAM=50

DEF REAL PIT=2, FFR=500, CPA=60,CPO=50

; Definition of the variable with valu e

assignments

N10 G90 G0 G1 7 X0 Y0 Z80 S200 M3

; Approach starting position

; Specification of technology values

N30 CYCL E90 (RTP, RFP , SDIS, DP, DP R, DI ATH, KDIAM, PIT,

FFR, CDI R, TYPTH, CPA, CPO)

; Approach position after cycle

Loading...

Loading...