Programming and Operating Manual (Milling)

6FC5398-4DP10-0BA6, 09/2017

335

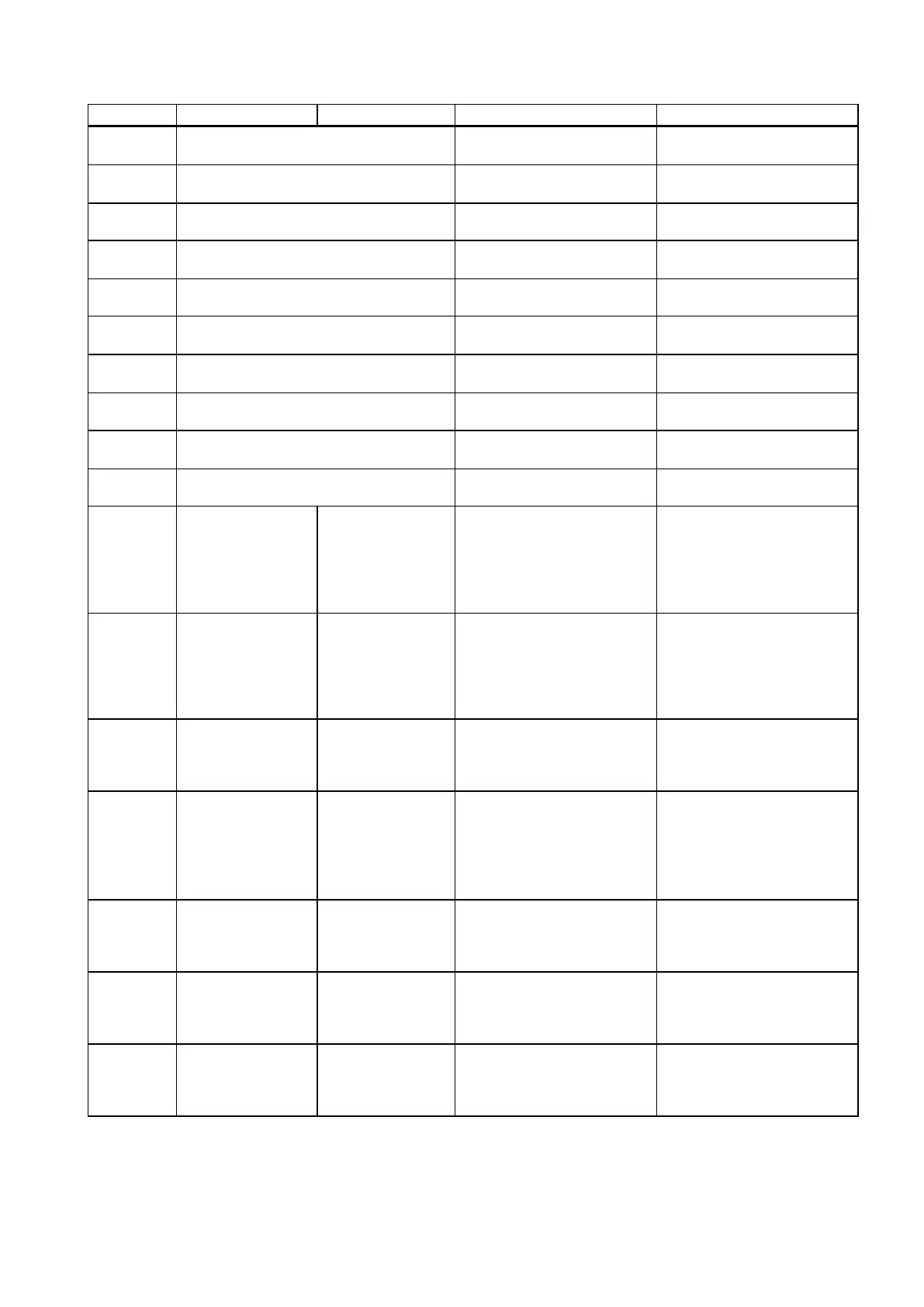

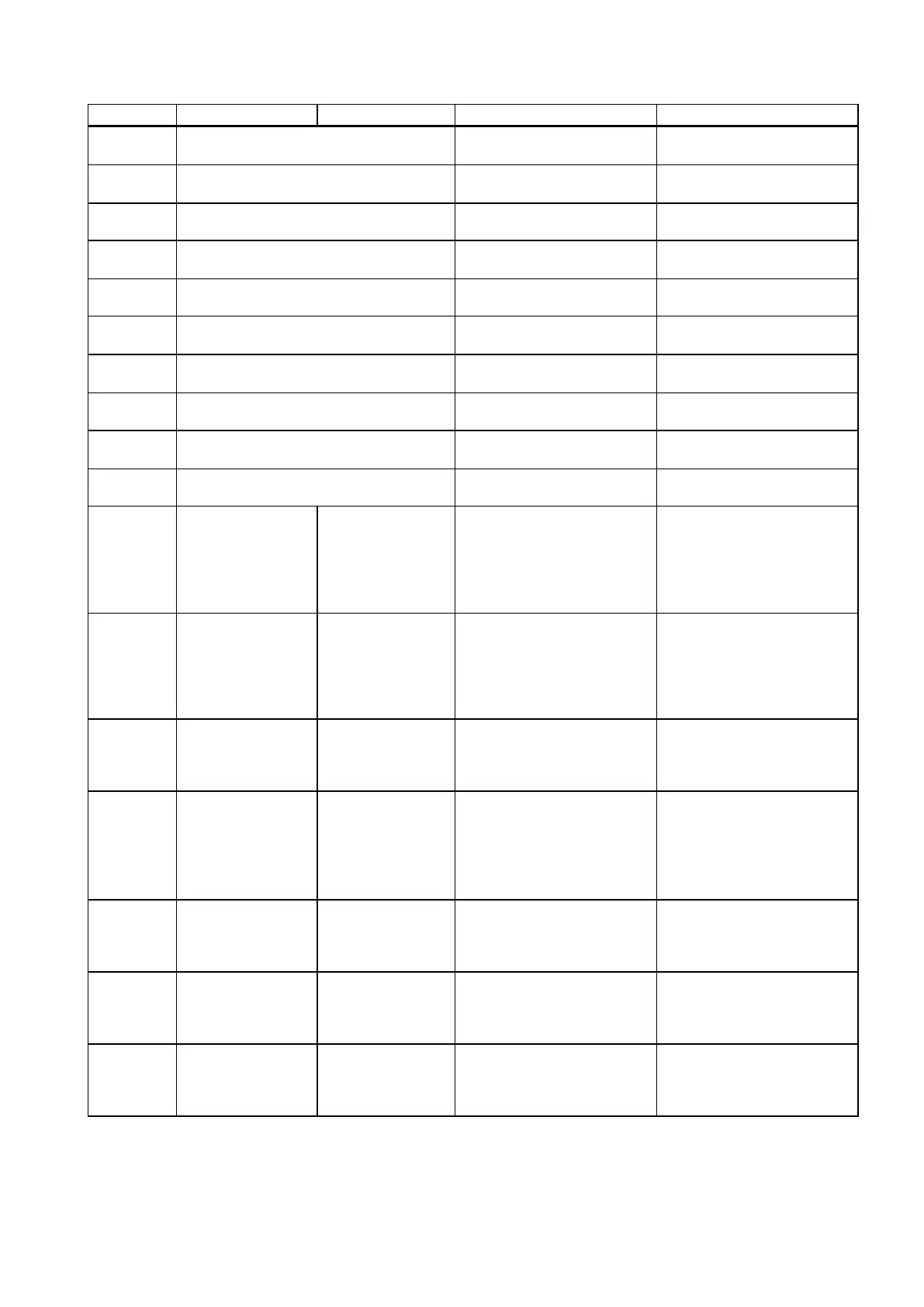

Mill a circumferential slot

N10 SLOT2(...); separate

block

N10 POCKET3(...); separate

block

N10 POCKET4(...); separate

block

N10 CYCLE71(...); separate

block

N10 CYCLE72(...); separate

block

Milling the rectangular spigot

N10 CYCLE76(...) ; separate

block

N10 CYCLE77(...) ; separate

block

N10 CYCLE90(...); separate

block

N10 LONGHOLE(...); separate

block

N10 CYCLE832(...); separate

block

Absolute coordinate;

approach position

directly (for rotary

axis, spindle)

It is also possible to specify

the dimensions for the end

point of a rotary axis with

DC(...) irrespective of

G90/G91; also applies to

spindle positioning

N10 A=DC(45.3); Approach

absolute position of the A axis

directly

N20 SPOS=DC(33.1); Position

spindle

Defining a user variable of the

BOOL, CHAR, INT, REAL,

STRING[n] type; define direct-

ly at the beginning of the pro-

gram

DEF INT VARI1=24, VARI2;

two variables of the INT type;

name defined by the user

DEF STRING[12]

VARS3="HELLO" ; max. 12

characters

Approach/retraction

distance of infeed

motion for machining

plane (SAR)

Safety clearance for speed

switchover for infeed motion;

note: G340, G341

See G147, G148, G247,

G248, G347, G348

Approach/retraction

distance or radius

(SAR)

G147/G148: Distance of the

cutter edge from the starting

or end point of the contour

G247, G347/G248, G348:

Radius of the tool center

pointpath

See G147, G148, G247,

G248, G347, G348

Velocity for the in-

feed (SAR)

Speed takes effect after the

safety clearance is reached for

the infeed;

note: G340, G341

See G147, G148, G247,

G248, G347, G348

Non-modal feedrate

for chamfer/rounding

When FRC=0, feedrate F will

act

For the unit, see F and G94,

G95;

for chamfer/rounding, see

CHF, CHR, RND

Modal feedrate for

chamfer/rounding

When FRCM=0, feedrate F

will act

For the unit, see F and G94,

G95;

for rounding/modal rounding,

see RND, RNDM

Loading...

Loading...