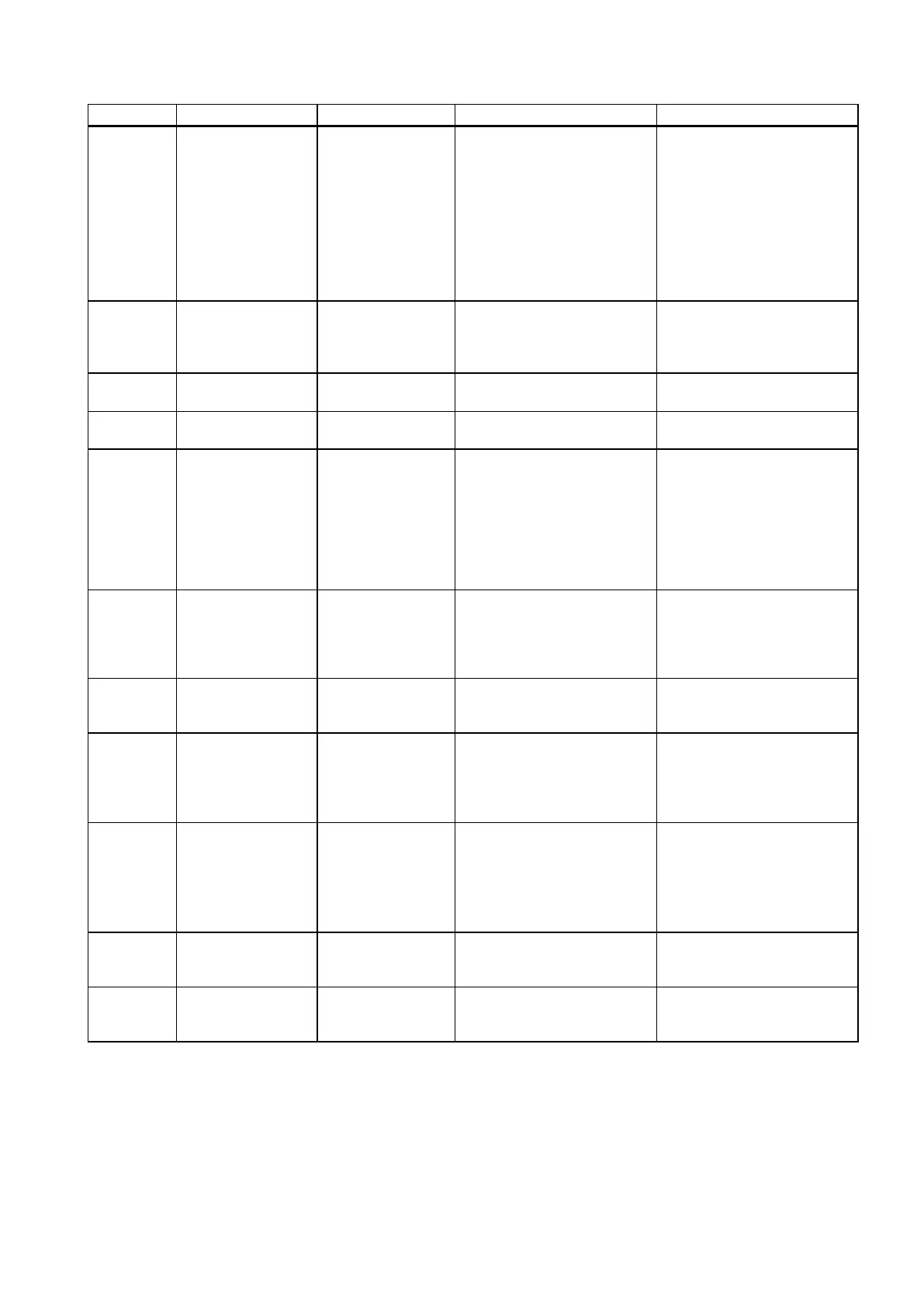

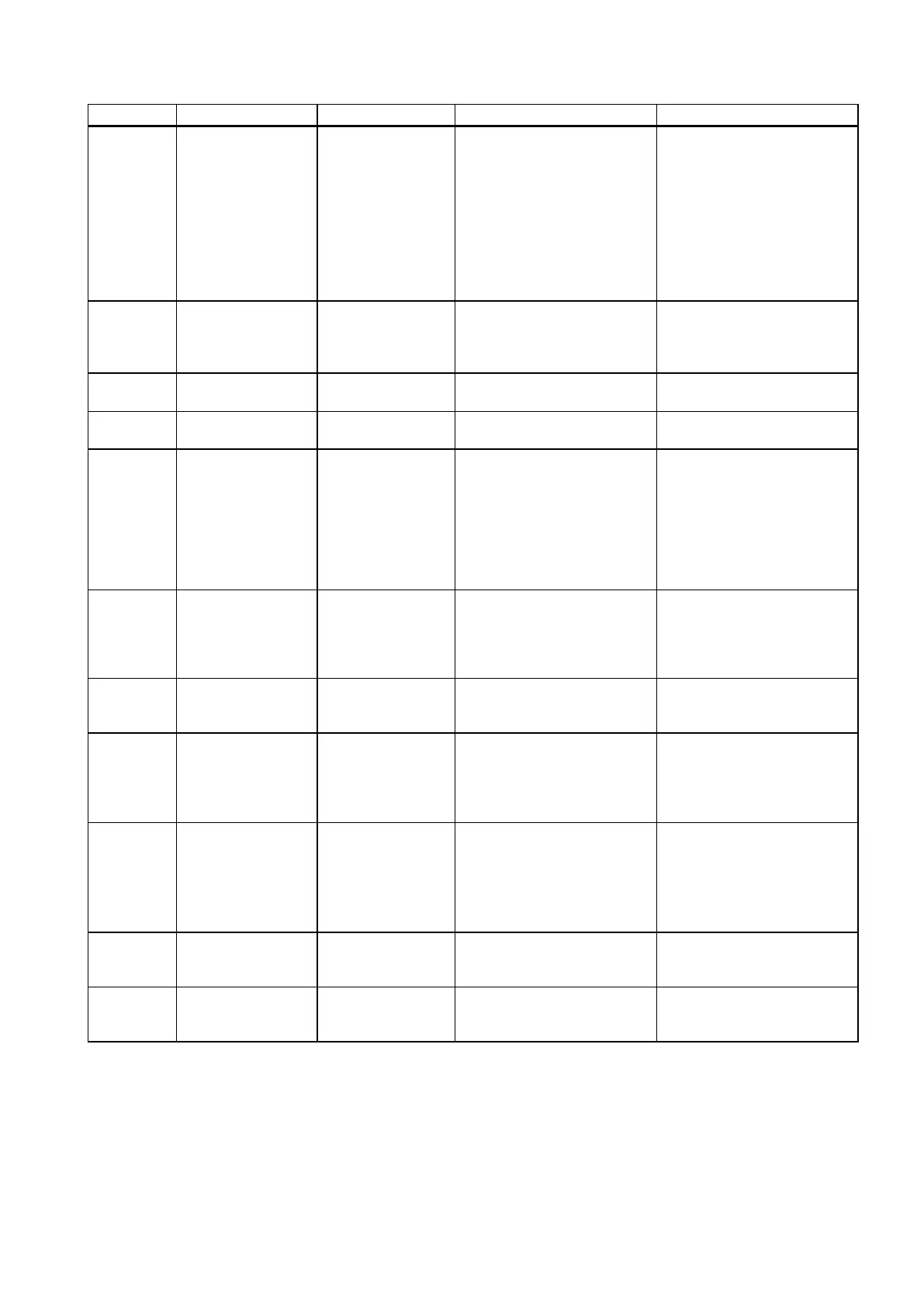

Workpiece counter:

$AC_TOTAL_PART

S

$AC_REQUIRED_P

ARTS

$AC_ACTUAL_PAR

TS

$AC_SPECIAL_PAR

TS

0 ... 999 999 999,

integer

System variable:

Total actual count

Set number of workpiece

Current actual count

Count of workpieces - speci-

fied by the user

N10 IF

$AC_ACTUAL_PARTS==15

....

Default condition:

0: Default condition, probe did

not switch

1: Probe switched

N10 IF $AC_MEAS[1]==1

GOTOF .... ; Continue pro-

gram when probe has

switched ...

Number of the active

tool T

N10 IF $P_TOOLNO==12

GOTOF ....

Active D number of

the active tool

N10 IF $P_TOOL==1 GOTOF

....

The subroutine in the block

containing MCALL is called

automatically after each suc-

cessive block containing a

path motion. The call acts until

the next MCALL is called.

Application example: Drilling a

hole pattern

N10 MCALL CYCLE82(...);

Separate block, drilling cycle

N20 HOLES1(...); Row of

holes

N30 MCALL; Separate block,

modal call of CYCLE82(...)

completed

Message text in inverted

commas

N10 MSG("MESSAGE

TEXT"); separate block

...

N150 MSG() ; Clear previous

message

Only effective with the tool

radius compensation G41,

G42 active

Inserts a rounding with the

specified radius value tangen-

tially between two contour

blocks, special FRC= ... feed

possible

N10 X... Y.... RND=4.5

N11 X... Y...

Inserts roundings with the

specified radius value tangen-

tially at the following contour

corners; special feedrate pos-

sible: FRCM= ...

Modal rounding OFF

N10 X... Y.... RNDM=.7.3;

modal rounding ON

N11 X... Y...

....

N100 RNDM=.0; modal round-

ing OFF

Traversing in polar coordi-

nates, pole specification; in

addition: Polar angle AP

See G0, G1, G2; G3, G110,

G111, G112

Angle of rotation

with ROT, AROT

Specification in degrees; angle

for a programmable rotation in

the current plane G17 to G19

Loading...

Loading...