Programming and Operating Manual (Milling)

6FC5398-4DP10-0BA6, 09/2017

61

Setting the time counter

Operating sequence

1.

Select the offset operating area.

Open the setting data window.

Open the time counter window.

4.

Position the cursor bar in the input fields to be modified and enter the values (see table

below for the parameter descriptions).

Use this key or move the cursor to confirm your entries.

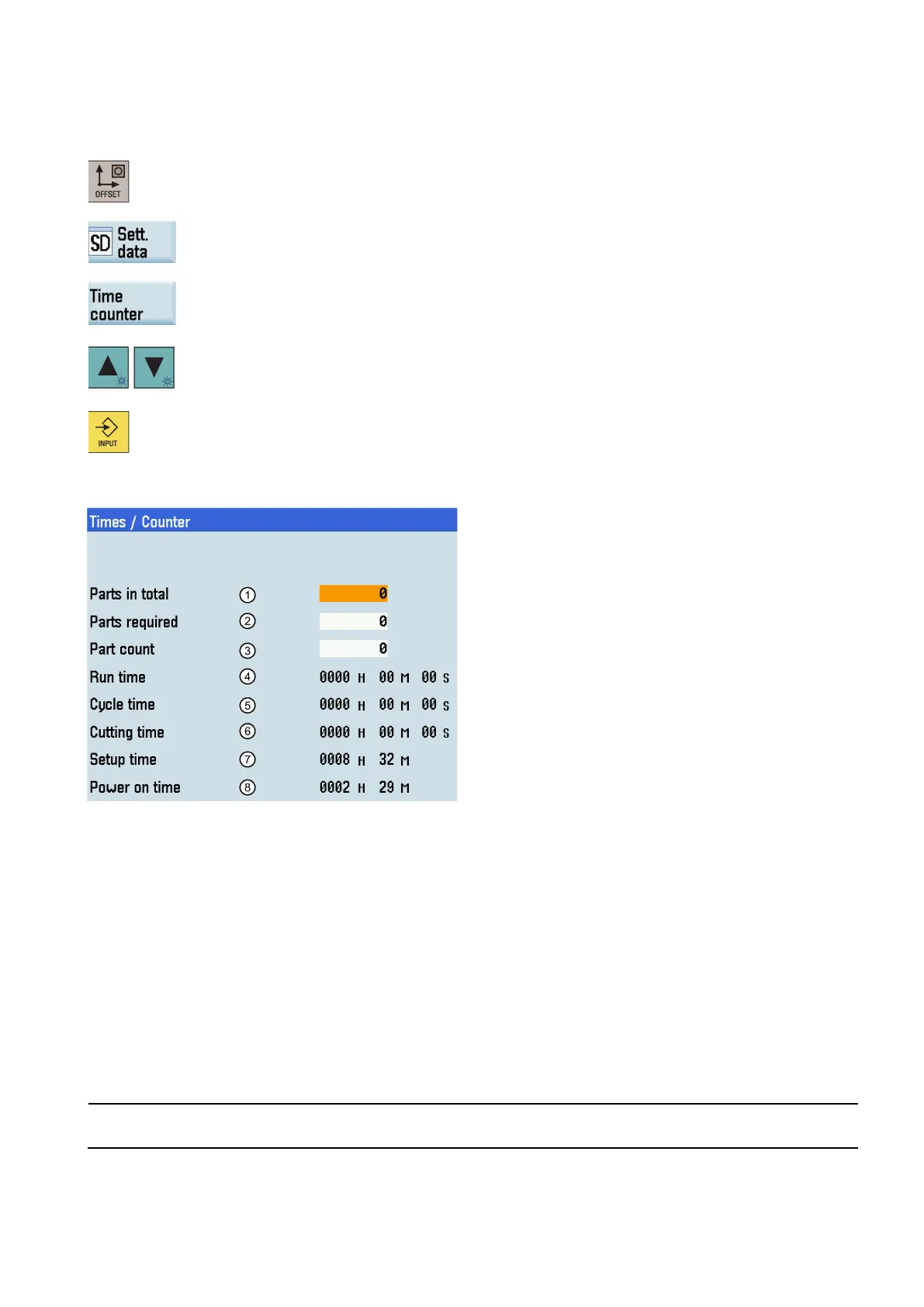

Parameters in the window for timers and workpiece counters

The total number of workpieces produced (total actual)

ces required (workpiece setpoint)

The number of all workpieces produced since the starting time

④

The total run time of NC programs in "AUTO" mode and the run time of all programs between NC start and end of

program/RESET. The timer is set to zero with each power-up of the control system.

The run time of the selected NC program in seconds

The default value is 0 each time a new NC program starts up. You can set MD27860 to ensure that this value will be

deleted even if there is a jump to the beginning

of the program with GOTOs or in the event of ASUPs (used for tool

change in "JOG" and "MM+" modes) and PROG_EVENTs starting.

⑥

Processing time in seconds

The time since the last system power

-up with default values ("cold restart") in minutes

e since the last normal system power-up ("warm restart") in minutes

The timer is automatically reset to zero in case of a control power-up with default values.

Loading...

Loading...