parameterization. It is not necessary to make any indication in the order. The optical Ethernet modules are

compatible with the EN100 modules of the SIPROTEC 4 series. If the RSTP protocol or the HSR protocol is

active, the optical modules of the SIPROTEC 4 series and the SIPROTEC 5 series can be operated in a ring.

When using SIPROTEC 4 devices with module firmware ≤ V4.05 and SIPROTEC 5 devices, the maximum allow-

able number of participants is 30 devices. When using SIPROTEC 4 devices with module firmware ≥ V4.07 and

SIPROTEC 5 devices, the maximum allowable number of participants is 40 devices. When using SIPROTEC 5

devices, the maximum allowable number of participants is 40 devices.

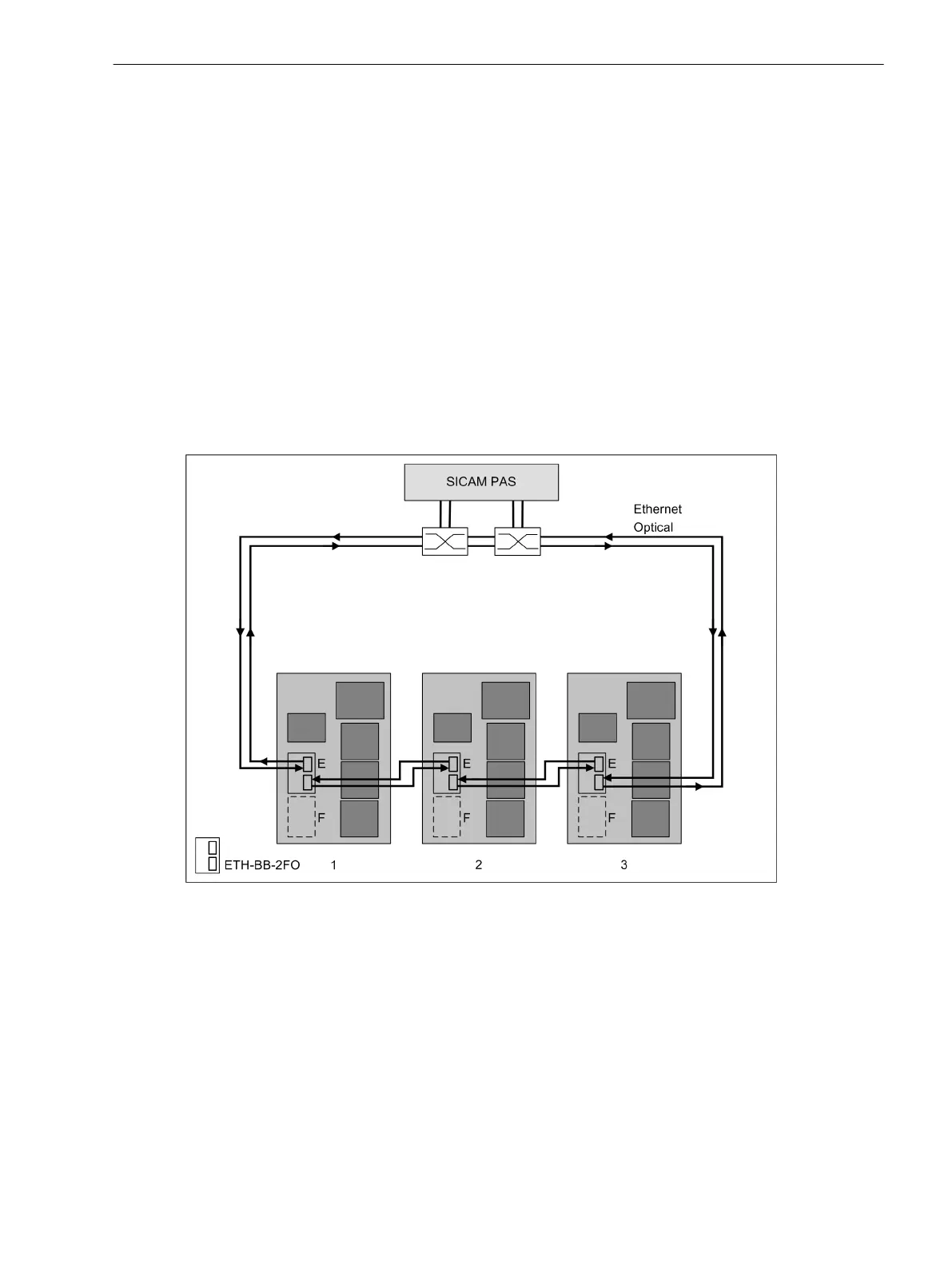

Figure 4-8 shows operation of the Ethernet modules with integrated switch function. All devices of a station

are shown which are connected to one another by means of optical fibers. The devices form optical rings. In

addition, 2 switches are used on the substation controller for the SICAM PAS. The 2 switches take the require-

ments for the redundancy into account.

Additional participants with electrical interfaces can also be connected to the SICAM PAS (for example, the

DIGSI 5 control PC). An external switch is sufficient. Optical communication modules are primarily used for this

topology, as there can be substantial distances between the devices.

If the Ethernet modules are installed in expansion modules with a CB202 PCB assembly, the power supply can

be provided with an independent battery. The integrated switch can maintain its function when the device is

switched off. The data are transmitted in optical and electric rings. This prevents opening of the ring. The ring

continues to operate when 1 or more devices are switched off.

[dweth1sw-030211-01.tif, 2, en_US]

Figure 4-8

Operation of Ethernet Modules with an Integrated Switch Function

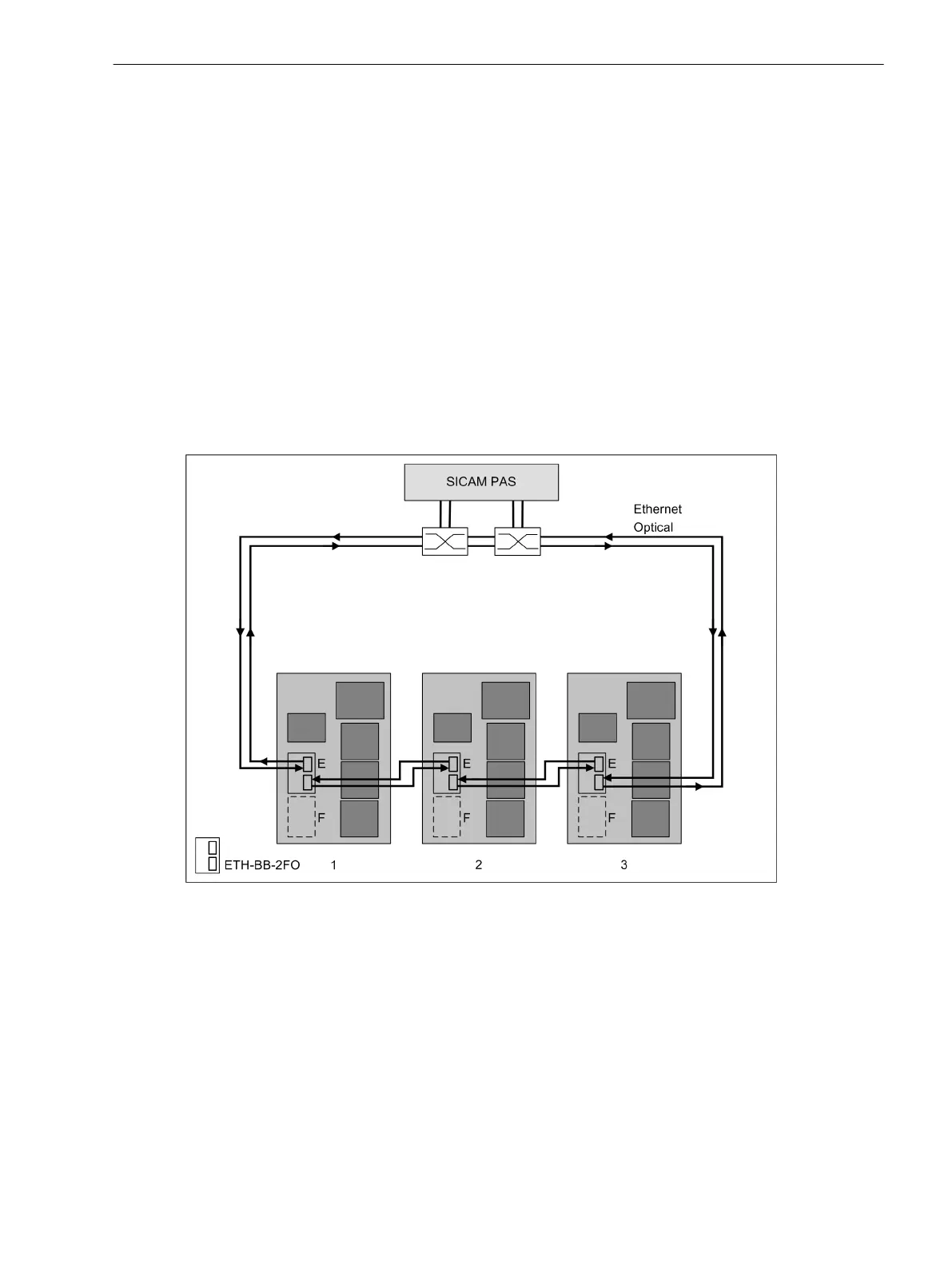

Figure 4-9 shows the operating mode without integrated switch function. Optionally, the 2nd connection can

be connected to the 2nd switch. This connection is shown with a dashed line in Figure 4-9. The IP communica-

tion is established using the 1st connection here. If this connection fails, the system changes over to the 2nd

connection within a few milliseconds. The IP connection is retained practically without interruption using the

2nd switch. This hot-standby connection redundancy increases the availability in such configurations, as

shown in the following figure. The information on failure of the protection connection is transmitted to the

substation automation technology.

Plug-In Modules

4.2 Communication Modules

SIPROTEC 5, Hardware Description, Manual 147

C53000-G5040-C002-C, Edition 10.2017

Loading...

Loading...