• AC1, AC2, BOOT1, and BOOT2 generate noise. Using shielding near these traces (by placing ground

planes below) is recommended.

• Power ground carries the sum of ripple current and DC current from the inverter. Current return paths from

LDO capacitors should be routed separately from these high current paths.

• AC1 and AC2 tracks should be routed close together to minimize the area of the resulting loop.

• Communication (I2C) and sensing signals should be routed far from noise generating nets (AC1, AC2,

BOOT1, and BOOT2) to minimize the effects of interference induced from those high di/dt nets.

• BOOT1, BOOT2 capacitors should be placed as close to the device as possible.

• Input and inverter decoupling capacitors should be placed close to the device to minimize the area of high

current loops.

• Auxiliary LDO capacitors should be placed as close to the device as possible.

• Thermal performance and grounding can be enhanced by dedicating one layer as a ground plane. No

signal/power tracks should be routed on this layer to ensure ground integrity.

6.4 Reference code with STM32 development boards

6.4.1 Hardware requirements

1. STM32 development board (for example, STM32 Nucleo-144)

2. STEVAL-WBC86TX

6.4.2 Hardware connections

1. Connect the STWBC86’s I2C pins to the master I2C bus. These signals require pull-up resistors to work

properly.

2. Power up STWBC86.

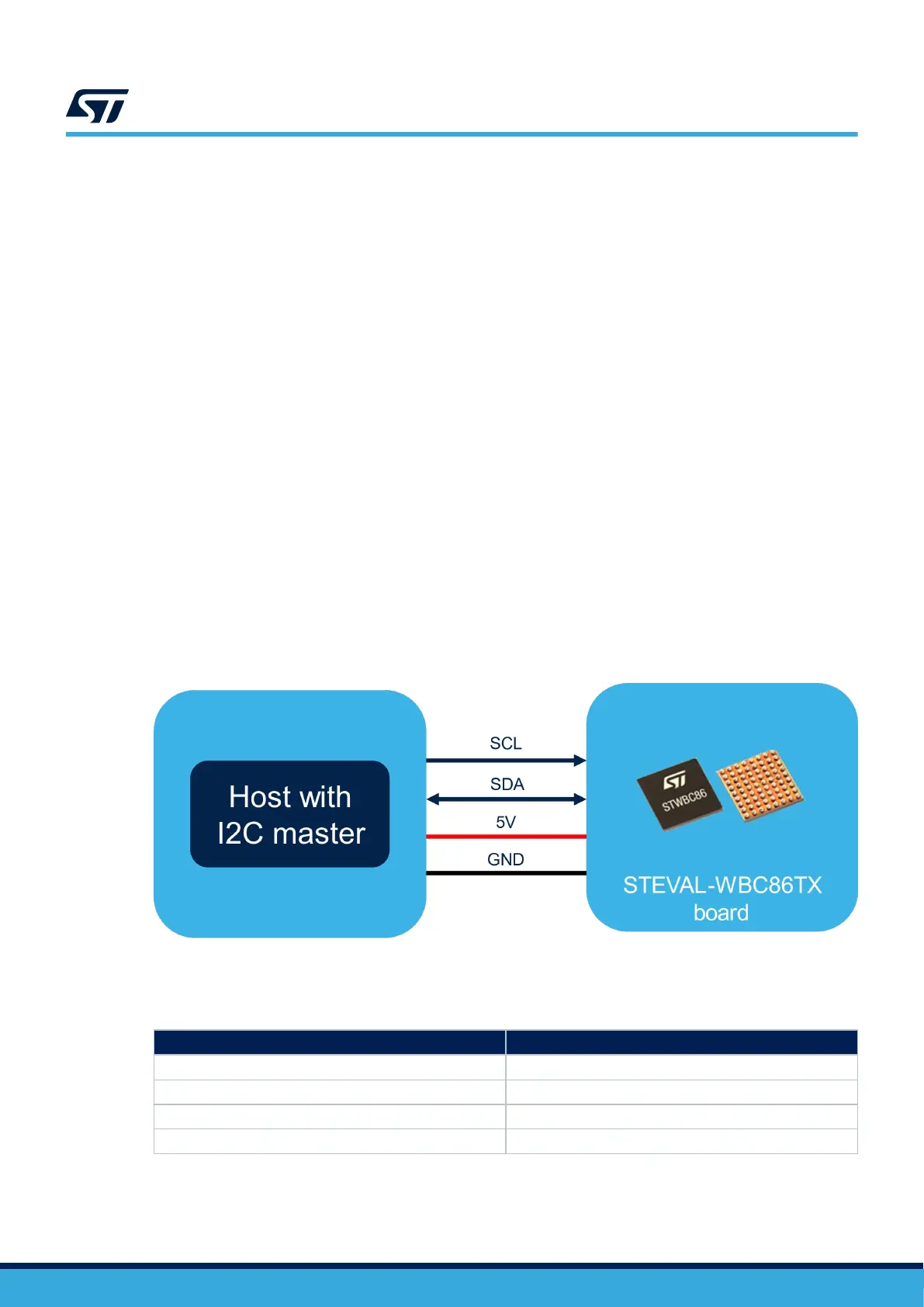

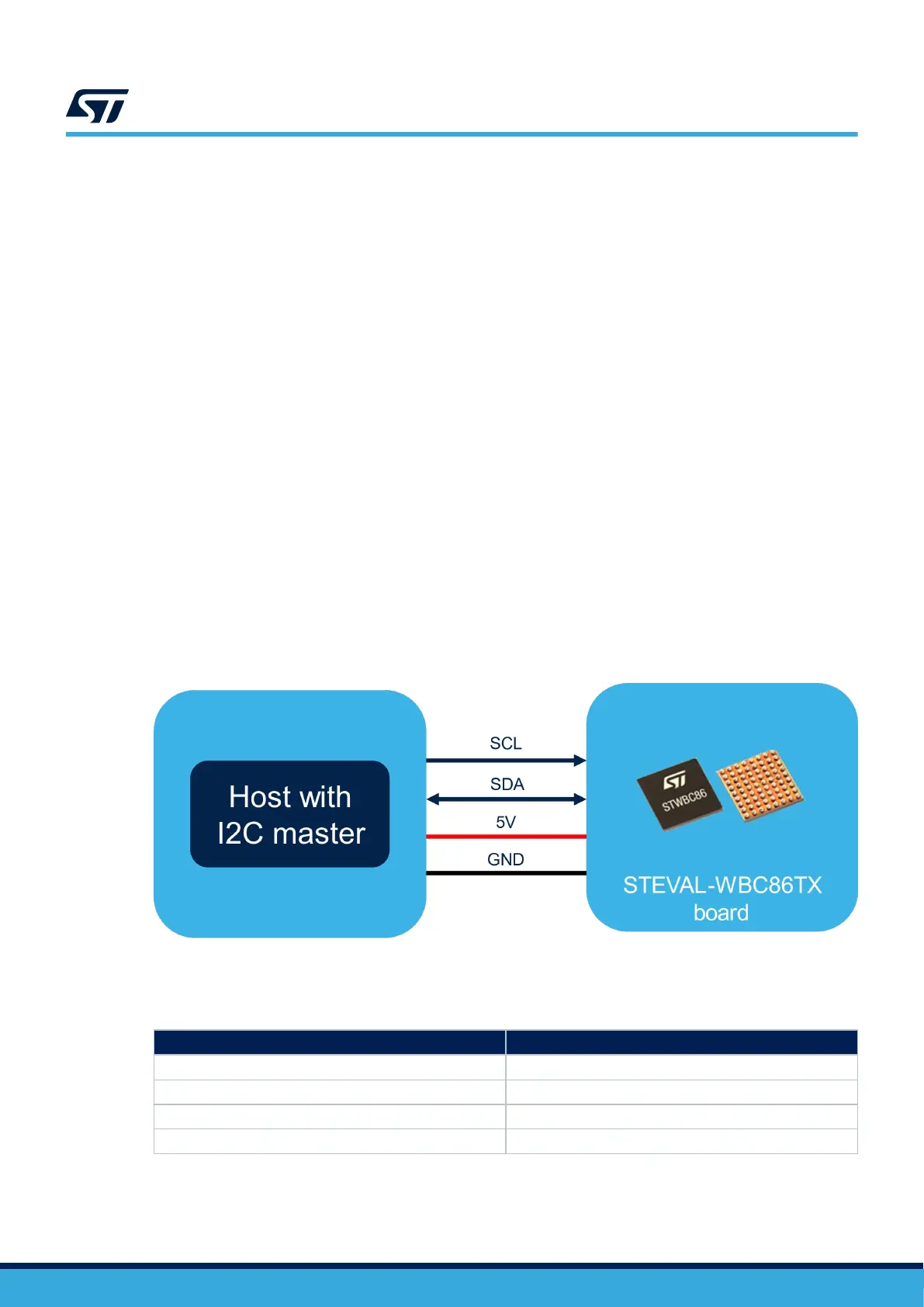

Figure 67. Pin connection between host and STWBC86 chip/evaluation board

STM32 Nucleo-144 board is used as an example.

Table 7. Pin connection between host (STM32) and STWBC86

STM32 Nucleo-144

STEVAL-WBC86TX board

5V (CN11.18) VIN

GND (CN11.20) GND

I2C1_SDA (PB9 -> CN12.5) SDA

I2C1_SCL (PB8 -> CN12.3) SCL

UM3161

Reference code with STM32 development boards

UM3161 - Rev 1

page 52/78

Loading...

Loading...