5756

8. Daily Inspection and Maintenance

- Gap Inspection

(1) Remove cover [8].

(2) Insert a gap gauge between the eld [4] and armature [12] and measure the

gap. Measure in 4 locations around the circumference.

(3) Adjustment is required if the gap value is near the limit.

- Gap Adjustment

(1) Manually release the brake following the procedure on P71.

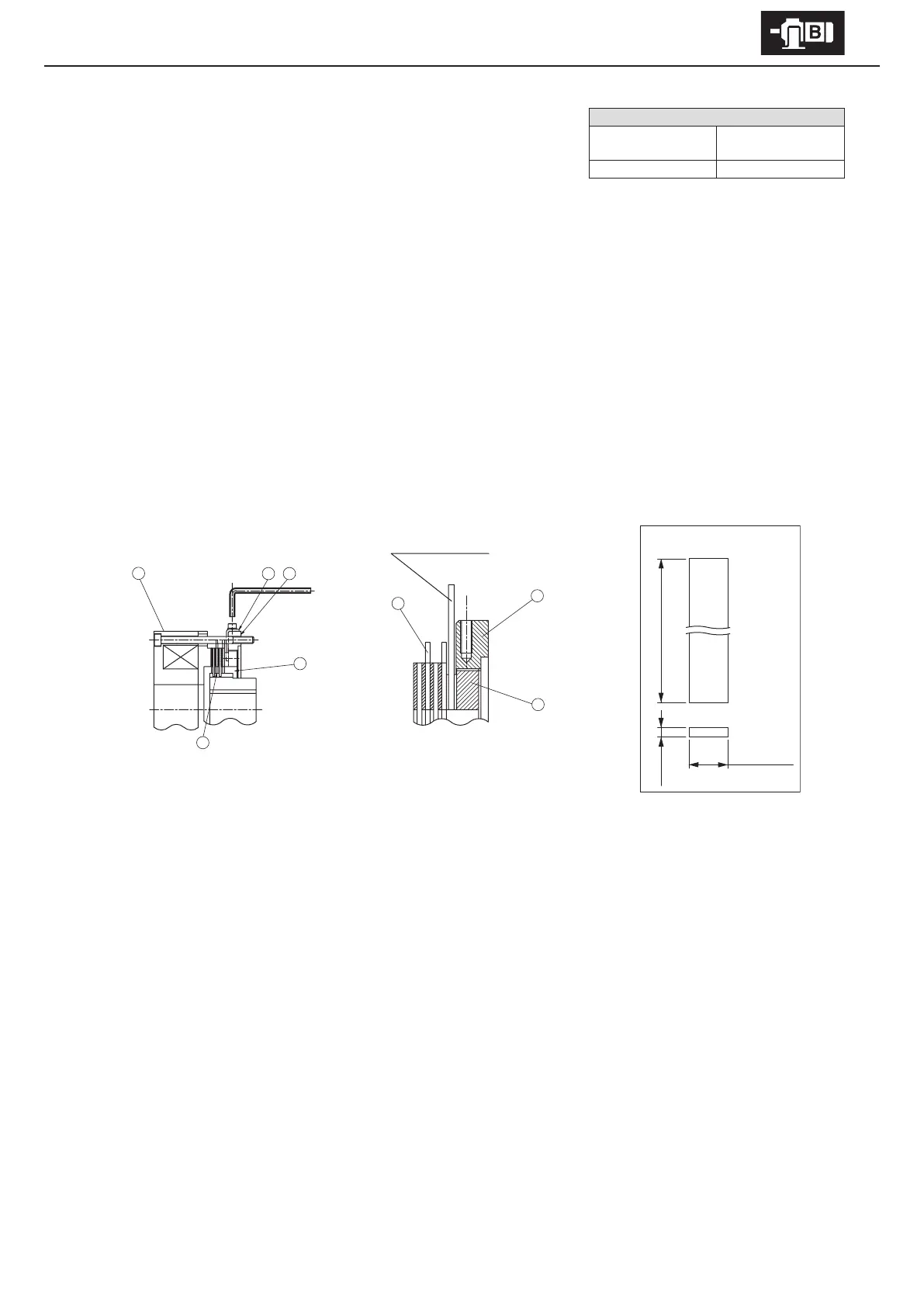

(2) Loosen the stopper [16] on the periphery of the center ring [1], and remove it. This will free the gap adjusting screws [2].

(See Figure 8-19)

(3) Insert the gap adjusting bar (customer to prepare an angle plate. See Figure 8-21) from between the outer disc [14] and the

center ring [1] into a hole for a gap adjusting screw [2].

Rotating to the left as seen from the eld [4] side, will narrow the gap. (See Figure 8-20)

(4) Six attachment bolts [3] and 6 lock bolts [11] alternately pass through the space between the outer disc [14] and the center ring

[1]. Rotating the gap adjusting bar will contact these bolts. There are 8 equally distributed holes for gap adjusting screws [2].

Adjust the gap G to the required value by repeating (3) each time the gap adjusting bar contacts a bolt,.

(5) Select the point where hole and screw hole are closest to the required gap and attach the stopper [16] there.

(6) After returning the manual brake release to its original state, turn power on and o to check brake action.

(7) Attach the fan [7] and cover [8]. At this time coat the fan set screw [10] with Three Bond TB2365.

4

16

1

2

14

Gap adjusting bar

2

1

14

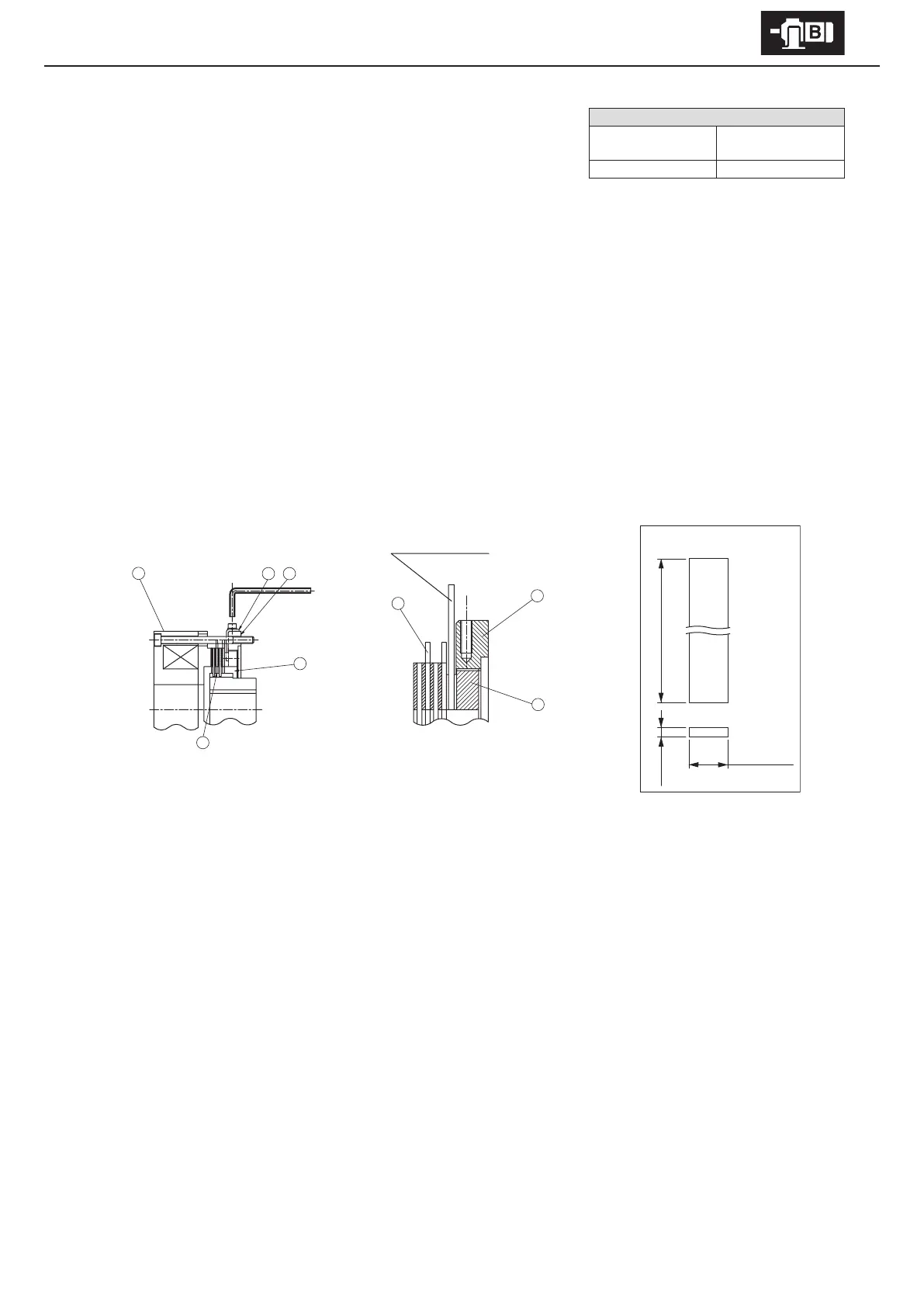

bar dimensions

14.7 ± 0.1 mm

150mm3.5 mm

Figure 8-19 Figure 8-20

Figure 8-21

Gap value G (mm)

Required value

(original value)

Limit value

0.7 2.0

Loading...

Loading...