5554

8. Daily Inspection and Maintenance

■

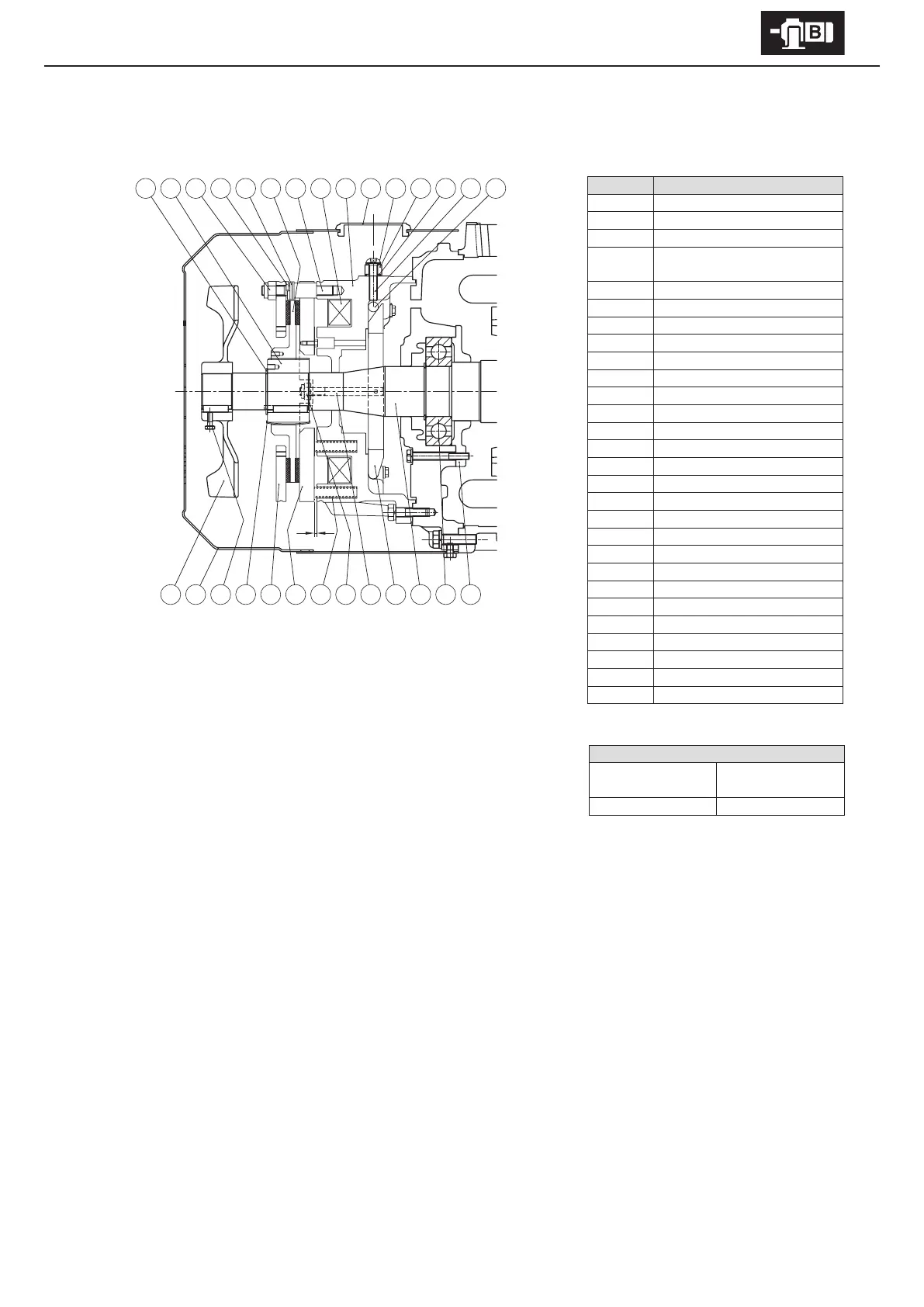

FB-30 (Indoor Type)

Code Part Name

1 Roller

2 Brake release bolt

3 Rubber packing

4

Manual release prevention

spacer

5 Seal washer

6 Stationary core

7 Electromagnetic coil

8 Stud bolt

9 Brake lining

10 Adjusting washer

11 Spring washer

12 Gap adjusting nut

13 Boss

14 Shaft-retaining C-ring

15 Fan

16 Cover

17 Fan set screw

18 Leaf spring

19 Fixed plate

20 Armature plate

21 Spring

22 Nut

23 Tap-end stud

24 Ball bearings

25 Release lever

26 Bearing cover

27 Motor shaft

28 Grommet

- Gap Inspection

(1) Remove the grommet [28] and cover [16].

(2) Insert a gap gauge between the stationary core [6] and the armature plate [12],

and measure the gap. Measure in 3 locations around the circumference.

(3) Adjustment is required if the gap value is near the limit.

- Gap Adjustment

(1) Remove the grommet [28] and cover [16].

(2) Insert a gap gauge between the stationary core [6] and the armature plate [20] and rotate to the right the gap adjusting nuts [12]

that are attached to ends of the stud bolts [8]. If large adjustments to the gap are not possible, decrease the number of adjust-

ing washers [10]. There are 3 gap adjusting nuts [12]. Adjust these in turn so that 3 positions on the circumference are uniformly

at the required gap.

(3) Turn the power on and o to check brake action.

(4) Attach the cover [16] and grommet [28].

Gap value G (mm)

Required value

(original value)

Limit value

0.6 – 0.7 1.5

123452867891011121314

15 18 19 20 21 22 2316 17 25 27 24 26

G

Figure 8-16

Loading...

Loading...