72

9. Troubleshooting

Common

If any abnormal condition occurs, refer to Table 9-1, 9-2 and promptly take appropriate measures.

If these actions do not remedy the issue, immediately contact the nearest authorized service station.

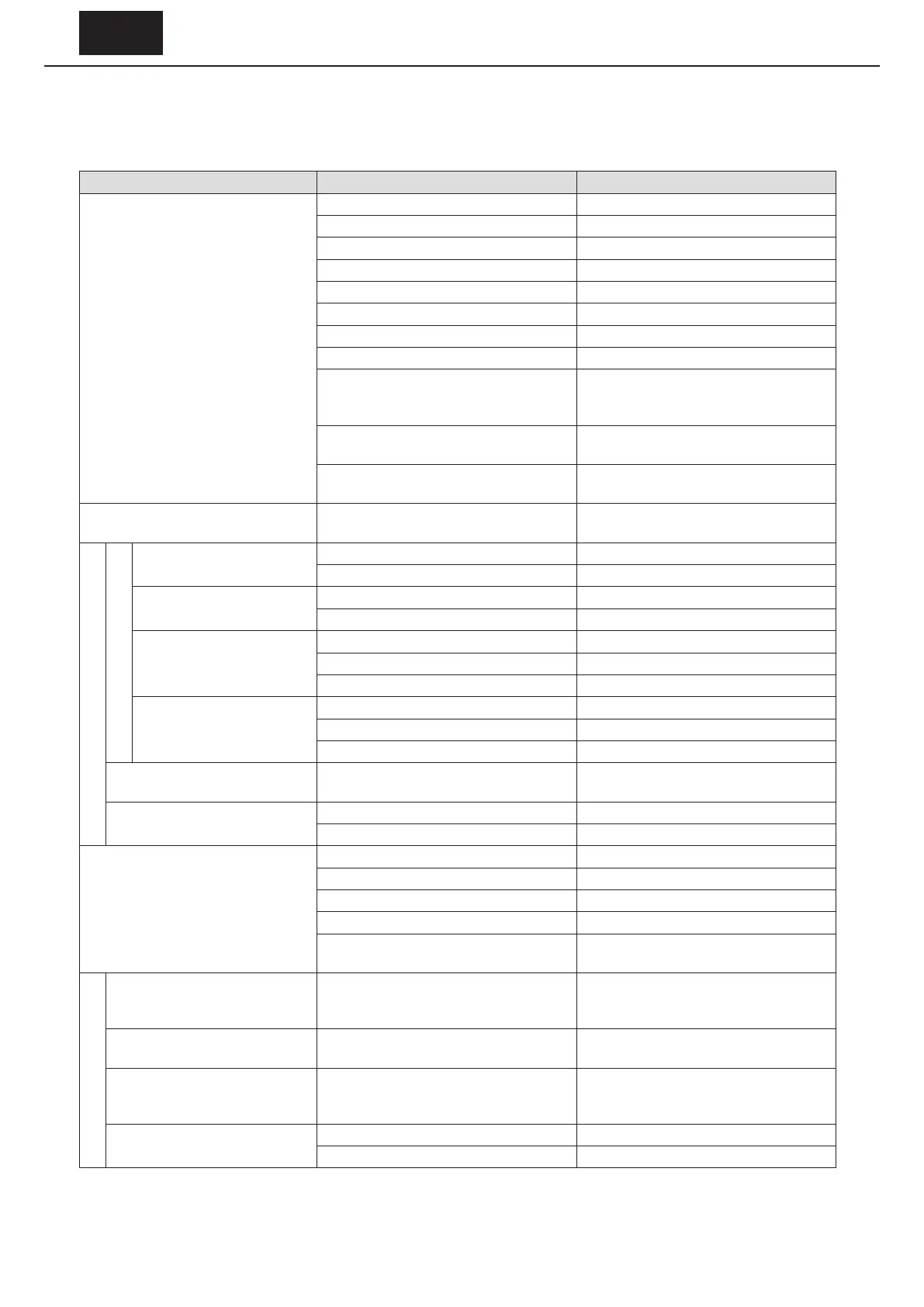

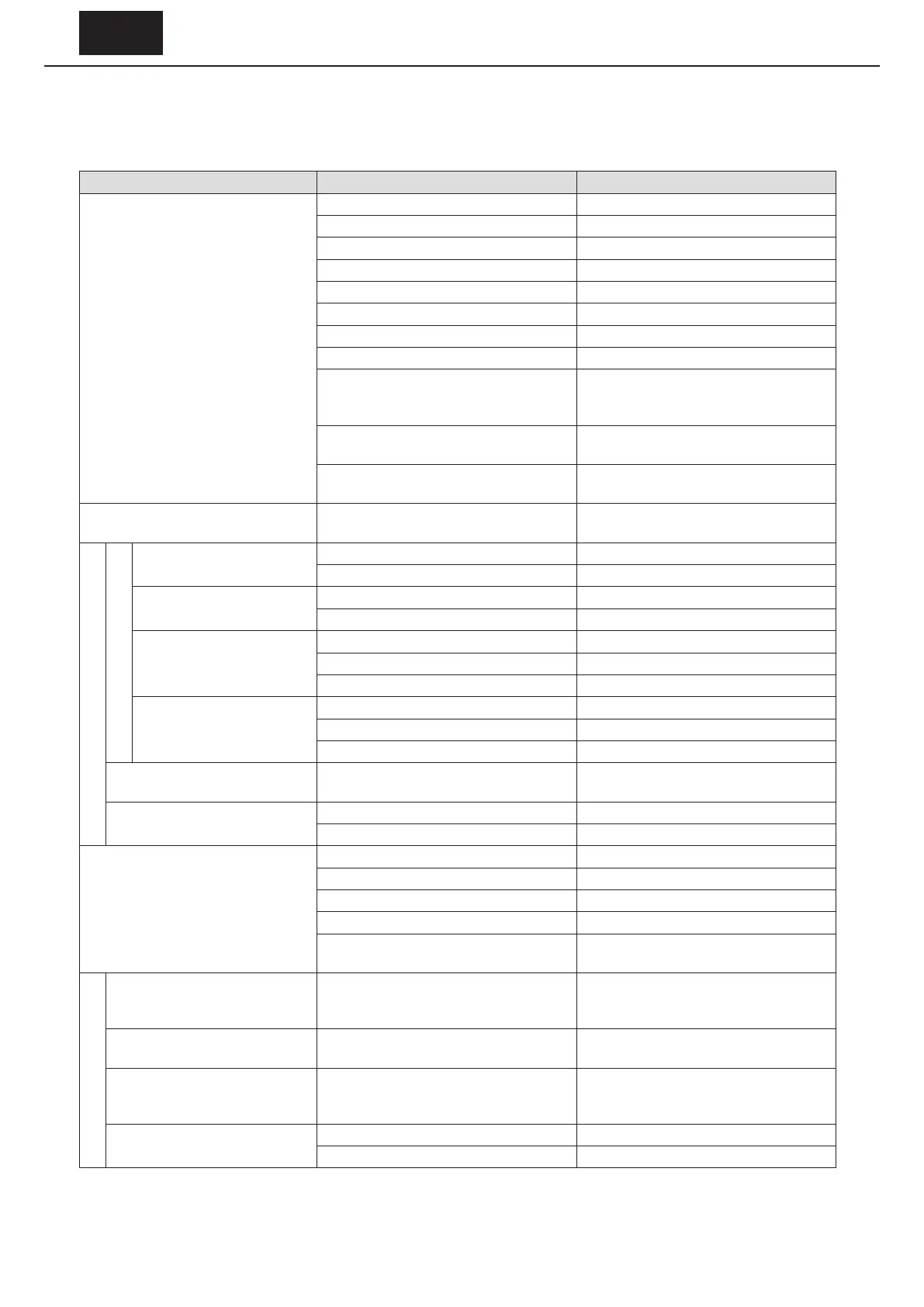

Table 9-1 Troubleshooting

Problem Cause Correction

The motor will not operate under no load

Power failure Contact the electric power company.

Defective electric circuit Check the circuit.

Blown fuse Replace the fuse.

Protective device is engaged Fix the problem and recover.

Load locking Check the load and safety device.

Poor switch contact Adjust the contact unit.

Motor stator coil disconnect Confer with authorized service station.

Bearing damage Confer with authorized service station.

3-phase is functioning as single-phase

Check the power supply with a voltmeter.

Check the motor, transformer coil, contactor,

fuse, etc. and repair or replace them.

Friction surface of brake is corroded

Request brake cleaning from authorized

service station.

Incorrect brake gap adjustment

Re-adjust brake gap.

(See P47 – 68)

The motor rotates without a load but the

slow speed shaft does not rotate

Damage to gear unit due to overloading of

gears, etc.

Confer with authorized service station.

The slow speed shaft turns without a load

When a load is applied

The switch overheats

Insucient switch capacity Replace with specied switch.

Overload Decrease the load to the specied value.

Fuse tripping

Insucient fuse capacity Replace with specied fuse.

Overload Decrease the load to the specied value.

The speed will not increase and

the motor is overheating

Voltage drop Contact the electric power company.

Overload Decrease the load to the specied value.

Short-circuited motor stator coil Confer with authorized service station.

It stops

The key is not inserted Insert key.

Bearing burnout Confer with authorized service station.

Poor adjustment of protection device Adjust the protection device.

The motor runs in the reverse

direction

Wiring error Change the connection.

Fuse tripping

The lead wire is short circuited. Confer with authorized service station.

Poor contact between motor and starter Make good connection.

Excessive temperature rise

Overload Decrease the load to the specied value.

Voltage drop or rise Contact the electric power company.

The ambient temperature is high Improve the ventilation method.

Damaged bearing Confer with authorized service station.

Abnormal wear of reducer parts due to

overload, etc.

Confer with authorized service station.

Oil leakage

Blot or drip of a small amount of

oil or grease at seal section of high

speed or slow speed shaft

Grease applied to the oil seal seeps out at rst Wipe o around the oil seal, and observe.

Leakage of oil or grease from high

speed or slow speed shaft section

Damaged oil seal or maybe damaged shaft (or

collar)

Confer with authorized service station.

Leakage of oil/grease from the

contact surfaces of ring gear housing

and casing, etc.

Loose fastener bolts Tighten fastener bolts correctly.

Leakage of oil/grease into motor

Damage to oil seals, or slinger collar Confer with authorized service station.

Excessive oil supply Remove oil.

Loading...

Loading...