7372

9. Troubleshooting

Common

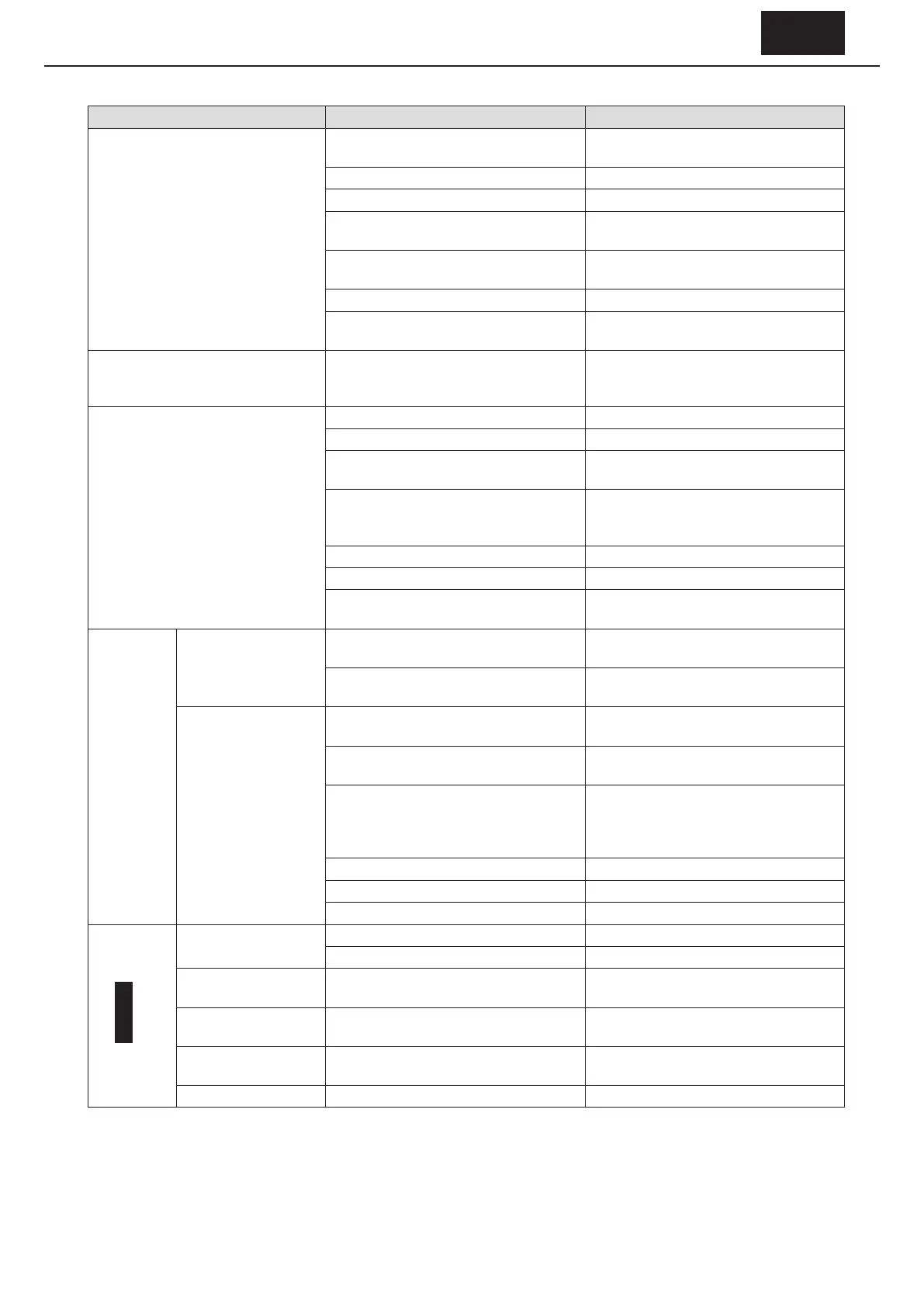

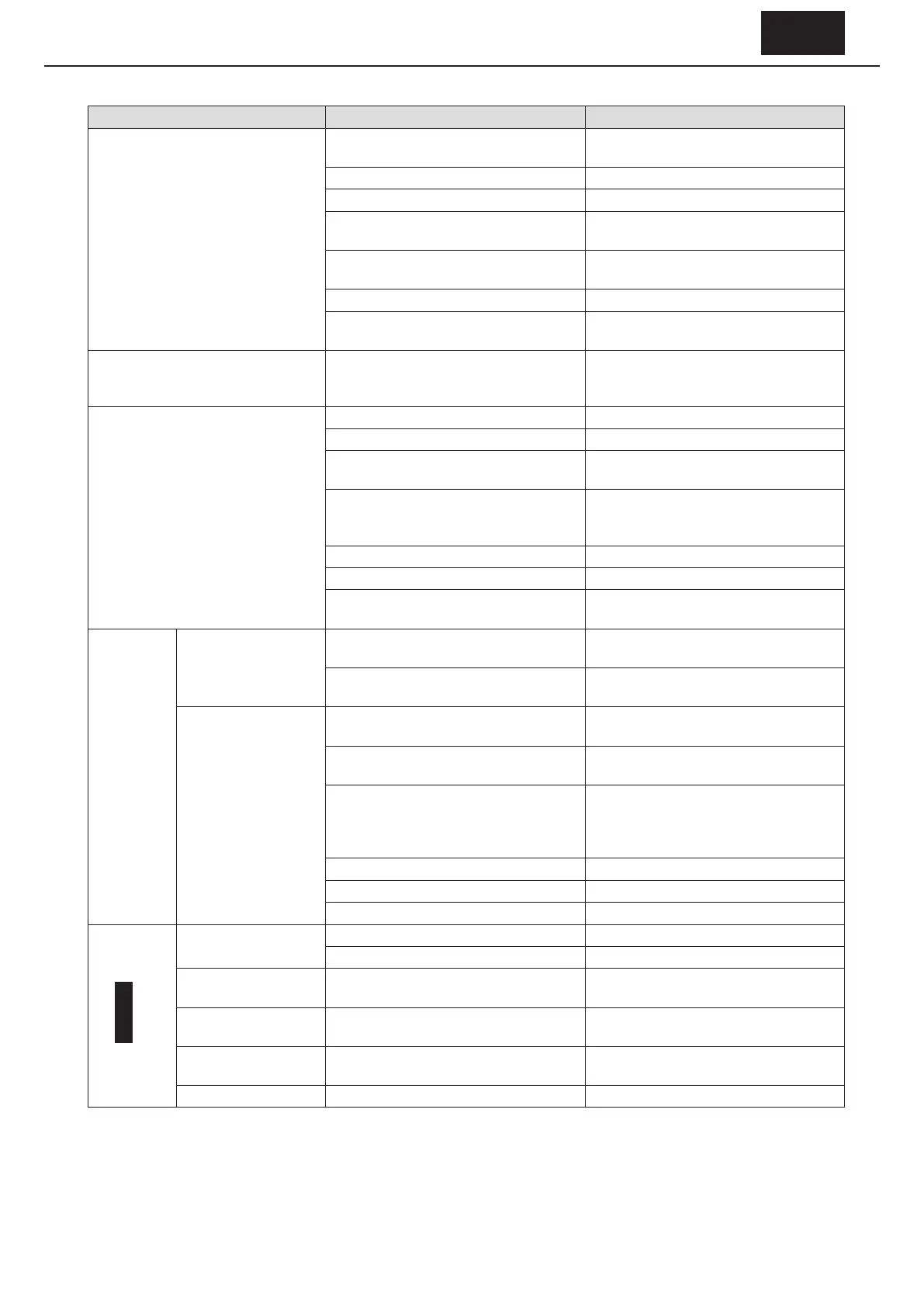

Table 9-2 Troubleshooting

Problem Cause Correction

Abnormal sound

Excessive vibration

Dust and foreign matter in bearings, or

damaged bearings

Confer with authorized service station.

Reducer parts grinding on foreign matter Confer with authorized service station.

Reducer parts are damaged Confer with authorized service station.

Warping of housing because the installation

surface is not at

Make the installation base at or make

adjustment using liners, etc.

Resonance due to insucient rigidity of

installation base

Reinforce the installation base to increase

rigidity.

Nonalignment of shaft with driven machine Align the shaft centers.

Transmission of vibration from the driven

machine

Individually operate the products to check

the source of the sound.

With torque limiter, makes chattering

sound

In rare cases this will occur in a low load

range. The inuence of load uctuation and

vibration from the device causes it.

Performance and lifetime are not aected.

It is OK to continue operation.

Abnormal motor sounds

Foreign objects have entered Confer with authorized service station.

Bearing damage Confer with authorized service station.

Improper brake gap adjustment

Adjust the brake gap.

(See P47 – 68)

Brake lining or inner disc wear

Request brake lining or inner disc

replacement from an authorized service

station.

Brake unit electromagnetic coil burnout Confer with authorized service station.

Rectier damage Confer with authorized service station.

Leaf spring in the brake boss unit has come

o or is damaged

Confer with authorized service station.

Brake is ineective

Does not activate

Forgot to restore the brake release bolt to its

original position

Restore the release bolt.

Improper adjustment after disassembly

Request authorized service station to

re-adjust.

Slips

(Braking takes a long

time)

Not using the quick braking circuit

Change to quick braking circuit.

(See P20 – 29)

Foreign objects in brake lining or inner disc

unit, oil adhesion

Request cleaning from authorized service

station.

Brake lining or inner disc wear

Adjust the brake gap.

Request brake lining or inner disc

replacement from an authorized service

station.

Brake gap not uniform Adjust the brake gap.

Overload Decrease the load to the specied value.

Brake release bolt not suciently restored Restore the release bolt.

Tripping

Inverter

Overcurrent shut-o

Sudden speed changes Increase the time for speed changes.

Extreme load uctuation Decrease load uctuation.

Overcurrent due to

ground fault

Ground fault on out side Take measures to prevent ground fault.

Direct current

overcurrent

Short on output side

Take measures to prevent short.

Inspect wiring.

Regenerative overvoltage

shut-o

Sudden speed reduction

Increase the time for speed reduction.

Decrease brake frequency.

Thermal operation Overload Decrease the load to the specied value.

Loading...

Loading...