64

8. Daily Inspection and Maintenance

■

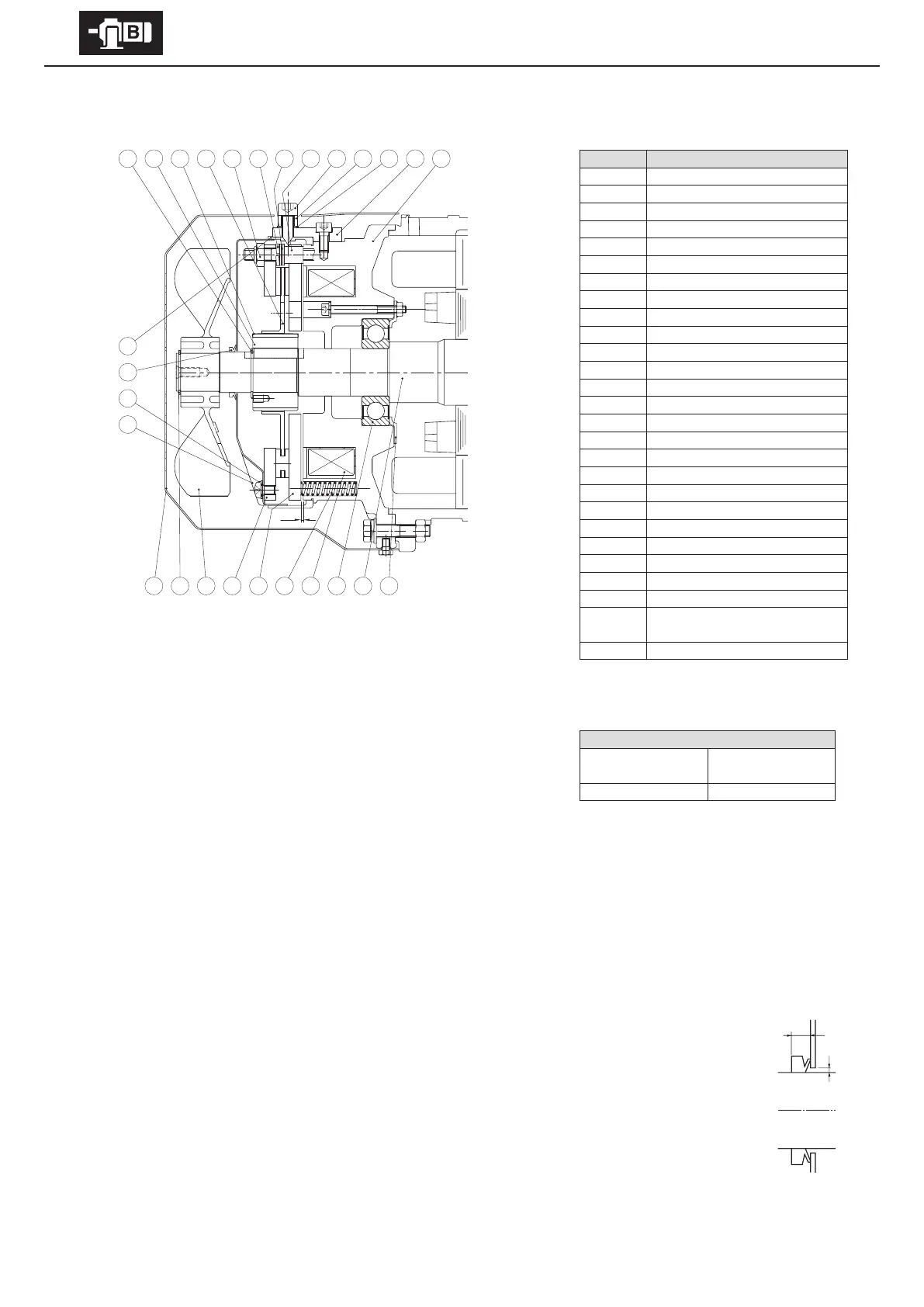

FB-10E, FB-15E (Outdoor Type)

Code Part Name

1 Stationary core

2 Brake release

3 Seal washer

4 Manual release prevention spacer

5 Brake release bolt

6 Stud bolt

7 Adjusting washer

8 Spring washer

9 Gap adjusting nut

10 Brake lining

11 Leaf spring

12 Boss

13 Shaft-retaining C-ring

14 Cover

15 Shaft-retaining C-ring

16 Fan

17 Fixed plate

18 Armature plate

19 Spring

20 Electromagnetic coil

21 Ball bearings

22 Motor shaft

23 Bearing cover

24 Waterproof seal

25 V-ring

26

Waterproof cover attachment

bolts

27 Waterproof cover

12345678910111213

14 15 16 17 18 19 20

G

24

25

26

27

- Gap Inspection

(1) Remove the brake release bolt [5] and the manual release prevention spacer [4].

(2) Remove the cover [14].

(3) Remove the shaft-retaining C-ring [15] and the fan [16].

(4) Remove the brake release [2] (2 locations) and remove the waterproof seal [24].

(5) Insert a gap gauge between the stationary core [1] and the armature plate [18]

and measure the gap. Measure in 3 locations around the circumference.

(6) Adjustment is required if the gap value is near the limit.

- Gap Adjustment

(1) Remove the brake release bolt [5] and the manual release prevention spacer [4].

(2) Remove the cover [14].

(3) Remove the shaft-retaining C-ring [15] and the fan [16].

(4) Pull o the V-ring [25].

(5) Remove the brake release [2] (2 locations) and remove the waterproof seal [24].

(6) Remove the waterproof cover attachment bolts [26], and remove the waterproof cover [27].

(7) Insert a gap gauge between the stationary core [1] and the armature plate [18] and rotate to the right the gap adjusting nuts [9]

that are attached to ends of the stud bolts [6]. If the gap is large, and adjustments are not possible, decrease the number of ad-

justment washers [7]. There are 3 adjusting nuts [9]. Adjust these in turn so that 3 positions on the circumference are uniformly

at the required gap.

(8) Attach the waterproof cover [27] using the waterproof cover attachment bolts [26]. At this time align the cutout

area on the side of the waterproof cover [27] with position of the brake release bolt [5]. Attach the waterproof

cover [27] so that the gap (A) between its hole and the motor shaft [22] is nearly uniform.

(9) Clean the surface of the waterproof seal [24] to remove impurities.

(10) As shown in the construction diagram, install the waterproof seal [24] between the stationary core [1] and the

waterproof cover [27]. Then attach the brake release [2]. Align the hole in the waterproof seal [24] for the brake

release bolt with the position of the release bolt [5]. Next, attach along the machined surfaces around the sta-

tionary core [1]. Be careful that the waterproof seal [24] does not meander. Otherwise water could leak in.)

(11) Turn the power on and o to check brake action.

(12) Attach the V-ring [24]. Wipe o the lip and surface near the lip of the V-ring [25], lightly coat the the lip contact

surface with grease, and attach. Observe the attaching dimension (B

=

6mm).

(13) Attach the fan [16], shaft-retaining C-ring [15] and cover [14].

(14) Finally, attach the brake release bolt [5] and the manual release prevention spacer [4].

Gap value G (mm)

Required value

(original value)

Limit value

0.35 – 0.45 1.2

B

A

Figure 8-28

Loading...

Loading...