86

Application

Product

14. Torque Indicator

14-1 Torque Indicator

(1) Checking the Torque Indicator

- The torque indicator is zero adjusted, and the preset torque is adjusted before shipment.

After the reducer has been connected to equipment, if zero is not indicated when the reducer is at rest, it is possible that a small load

is already being applied to the output shaft. Do not readjust the zero point.

- The relationship between the direction of pointer deection and slow speed shaft rotation (seen from the slow speed shaft side) is

shown below.

Single reduction type: pointer opposite direction of the slow speed shaft

Double, triple reduction types: pointer in the same direction as the slow speed shaft

- The indicator scale displays the load factor, with 100% being the preset torque. Accuracy is within 10% of the overall load range.

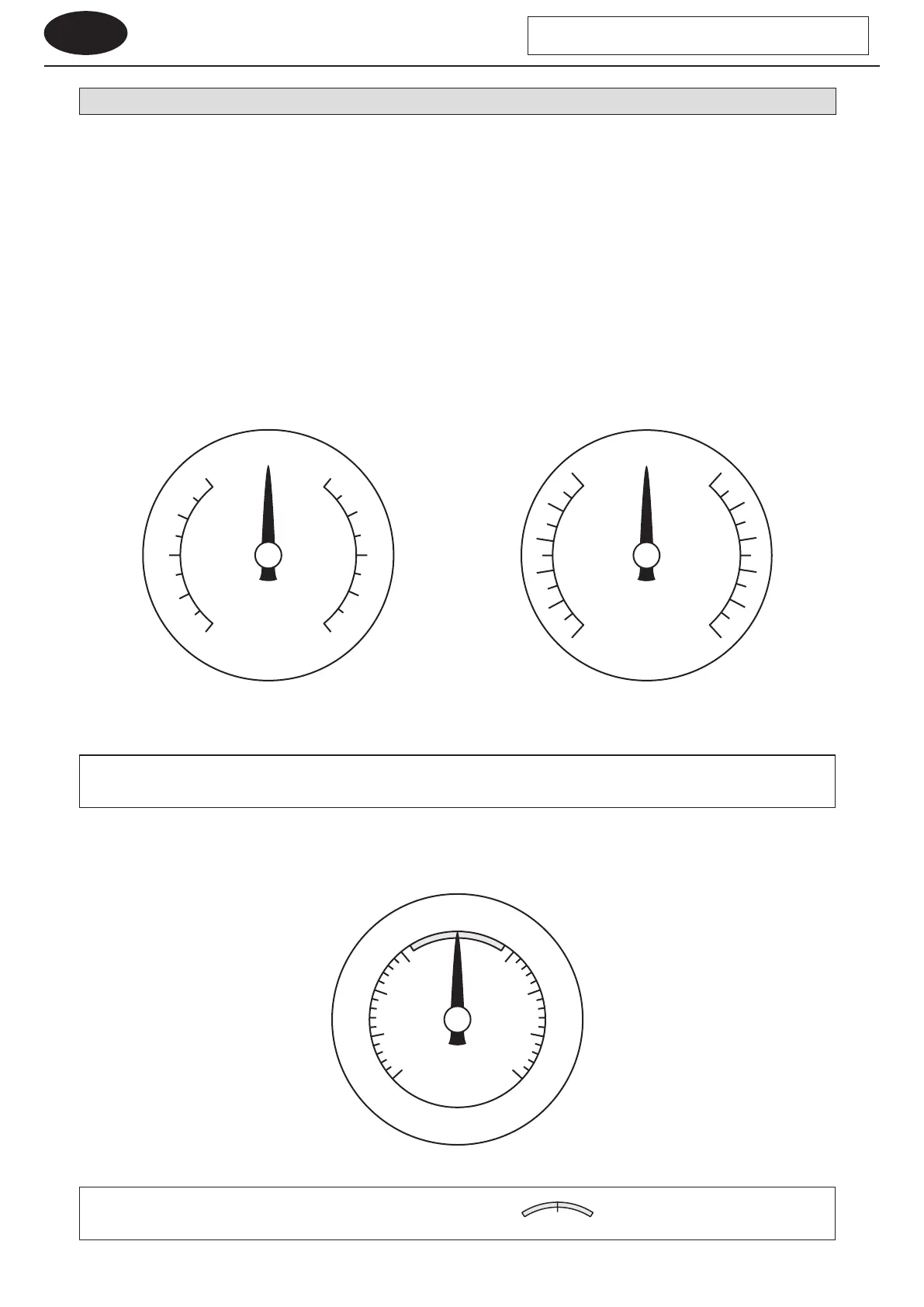

(2) A-Type Torque Indicator

The A-type torque indicator displays load factors of 60 – 100% (depending on the combination of preset torque and reduction ratio

50 – 100%).

60 60

70 70

80 80

90 90

100 100

%

%

50

100 100

50

60 60

90

70 70

80 80

90

Figure 14-1 A-Type Torque Indicator

(60 – 100% load factor display)

Figure 14-3 B-Type Torque Indicator (0 – 100% load factor display)

Figure 14-2 A-Type Torque Indicator

(50 – 100% load factor display)

- The pointer may deect slightly when stopped or under no load. This is not a problem.

- For the reversible rotation specication, when left and right preset torques dier, the pointer position will be slightly oset.

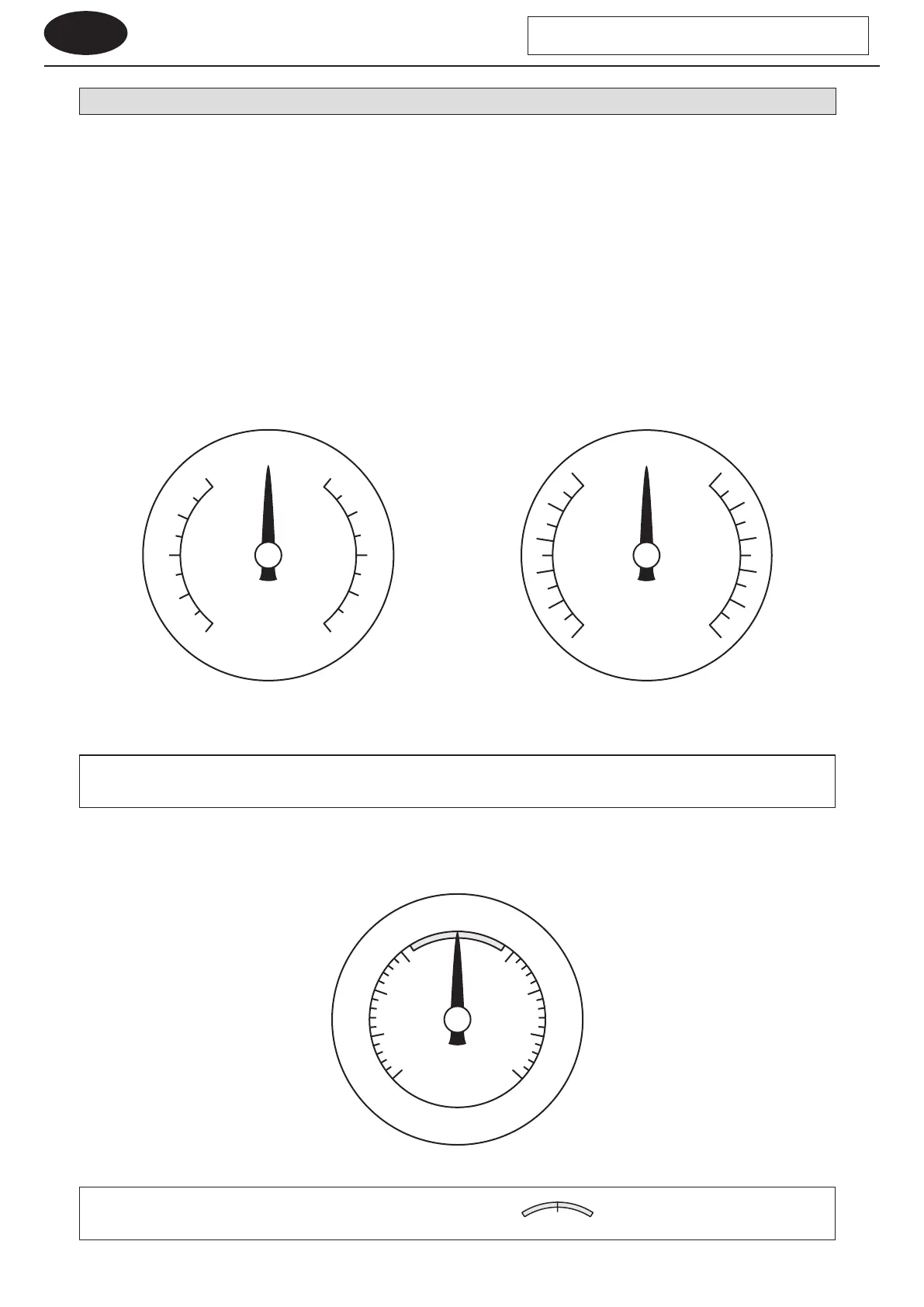

(3) B-Type Torque Indicator

The B-type torque indicator displays load factors of 0 – 100%.

- In the case of a B-type torque indicator, the pointer will stop in the range of when load is removed.

- Preset torque cannot be changed. Do not turn the adjustment bolt.

%

0

25 25

50 50

75 75

100 100

CYCLO Drive with Torque Limiter

Loading...

Loading...