62

8. Daily Inspection and Maintenance

■

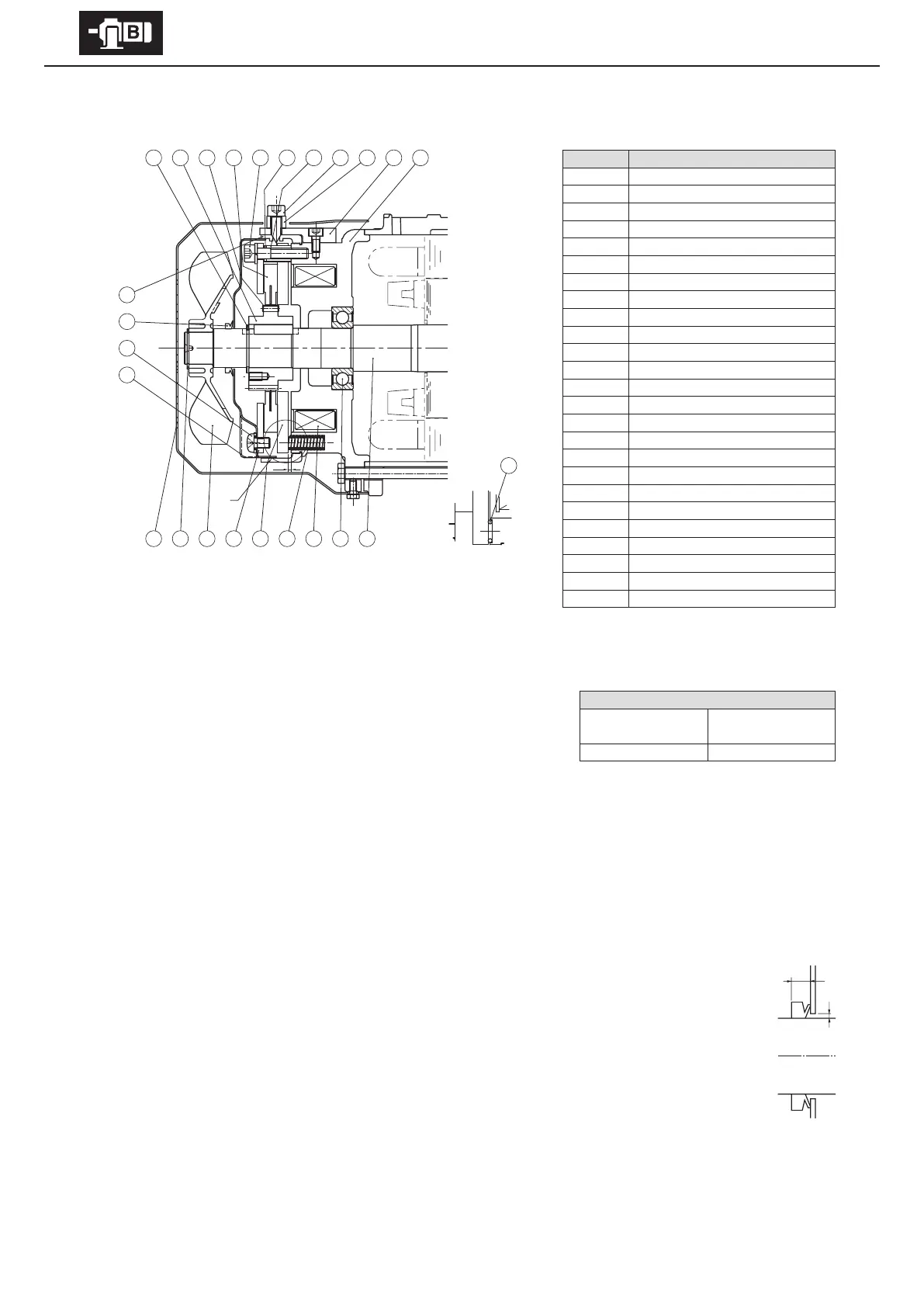

FB-3E, FB-4E (Outdoor Type)

Code Part Name

1 Stationary core

2 Brake release

3 Manual release prevention spacer

4 Brake release bolt

5 Spacer

6 Gap adjusting shims

7 Attachment bolt

8 Brake lining

9 Leaf spring

10 Boss

11 Shaft-retaining C-ring

12 Cover

13 Shaft-retaining C-ring

14 Fan

15 Fixed plate

16 Armature plate

17 Spring

18 Electromagnetic coil

19 Ball bearings

20 Motor shaft

21 Waterproof seal

22 V-ring

23 Waterproof cover attachment bolts

24 Waterproof cover

25 Shock absorber

1234567891011

G

12 13 14 15 16 17 18 19 20

21

22

23

24

X

25

- Gap Inspection

(1) Remove the brake release bolt [4] and the manual release prevention

spacer [5].

(2) Remove the cover [12].

(3) Remove the shaft-retaining C-ring [13] and the fan [14].

(4) Remove the brake release [2] (2 locations) and remove the waterproof seal [21].

(5) Insert a gap gauge between the stationary core [1] and the armature plate [16]

and measure the gap. Measure in 3 locations around the circumference.

(6) Adjustment is required if the gap value is near the limit.

(Gap adjustment shim thickness is approximately 0.45 – 0.55 mm. Adjustment

cannot be made at a lower value.)

- Gap Adjustment

(1) Remove the brake release bolt [4] and the manual release prevention spacer [5].

(2) Remove the cover [12].

(3) Remove the shaft-retaining C-ring [13] and the fan [14].

(4) Pull o the V-ring [22].

(5) Remove the brake release [2] (2 locations) and remove the waterproof seal [21].

(6) Remove the waterproof cover attachment bolts [23], and remove the waterproof cover [24].

(7) Loosen the attachment bolts [7] and remove the spacers [5], gap adjustment shims [6], attachment bolts [7] and xed plate [15]

as a set. When removing the attachment bolts [7] make certain not to omit the gap adjustment shims [6] or the shock absorber

[25].

(8) The gap adjustment shims [6] have a thickness of 0.45 – 0.55 mm. Reduce the number of shims according to the

wear conditions, then reassemble the spacers [5], gap adjustment shims [6], attachment bolts [7] and xed plate

[15] as a set.

(9) Check the gap G, and readjust the shims if there is a large dierence between it and the required value.

(10) Attach the waterproof cover [24] using the waterproof cover attachment bolts [23]. At this time align the cutout

area on the side of the waterproof cover [24] with the brake release bolt [4]. Attach the waterproof cover [24] so

that the gap (A) between its hole and the motor shaft [20] is nearly uniform.

(11) Clean the surface of the waterproof seal [21] to remove impurities.

(12) As shown in the construction diagram, install the waterproof seal [21] between the stationary core [1] and the

waterproof cover [24]. Then attach the brake release [2]. Align the hole in the waterproof seal [21] for the brake

release bolt with the position of the release bolt [4]. Attach the waterproof seal [21] so that its protrusion ts

snuggly around the entire circumference of the groove for the stationary core [1]. (Be careful that the waterproof

seal [21] does not meander. Otherwise water could leak in.)

(13) Turn the power on and o to check brake action.

(14) Attach the V-ring [22]. Wipe o the lip and surface near the lip of the V-ring [22], lightly coat the the lip contact surface with

grease, and attach. Observe the attaching dimension (B

=

6mm).

(15) Attach the fan [14], shaft-retaining C-ring [13] and cover [12].

(16) Finally, attach the brake release bolt [4] and the manual release prevention spacer [3].

Gap value G (mm)

Required value

(original value)

Limit value

0.25 – 0.35 0.85

B

A

Figure 8-26

Loading...

Loading...