3333

6. Wiring

6-7 Wiring for Motorized Trochoid Pump Motor

CAUTION

- When lubricating with a motorized trochoid pump, always prime before starting the main motor. Abnormal temperature

rise, seizure, and other device damage may occur.

(1)

Vertical frame sizes 6275, 6275DA Use a trochoid pump for independent lubrication. The pump requires a separate power source.

(See Table 6-5, gure 6-4)

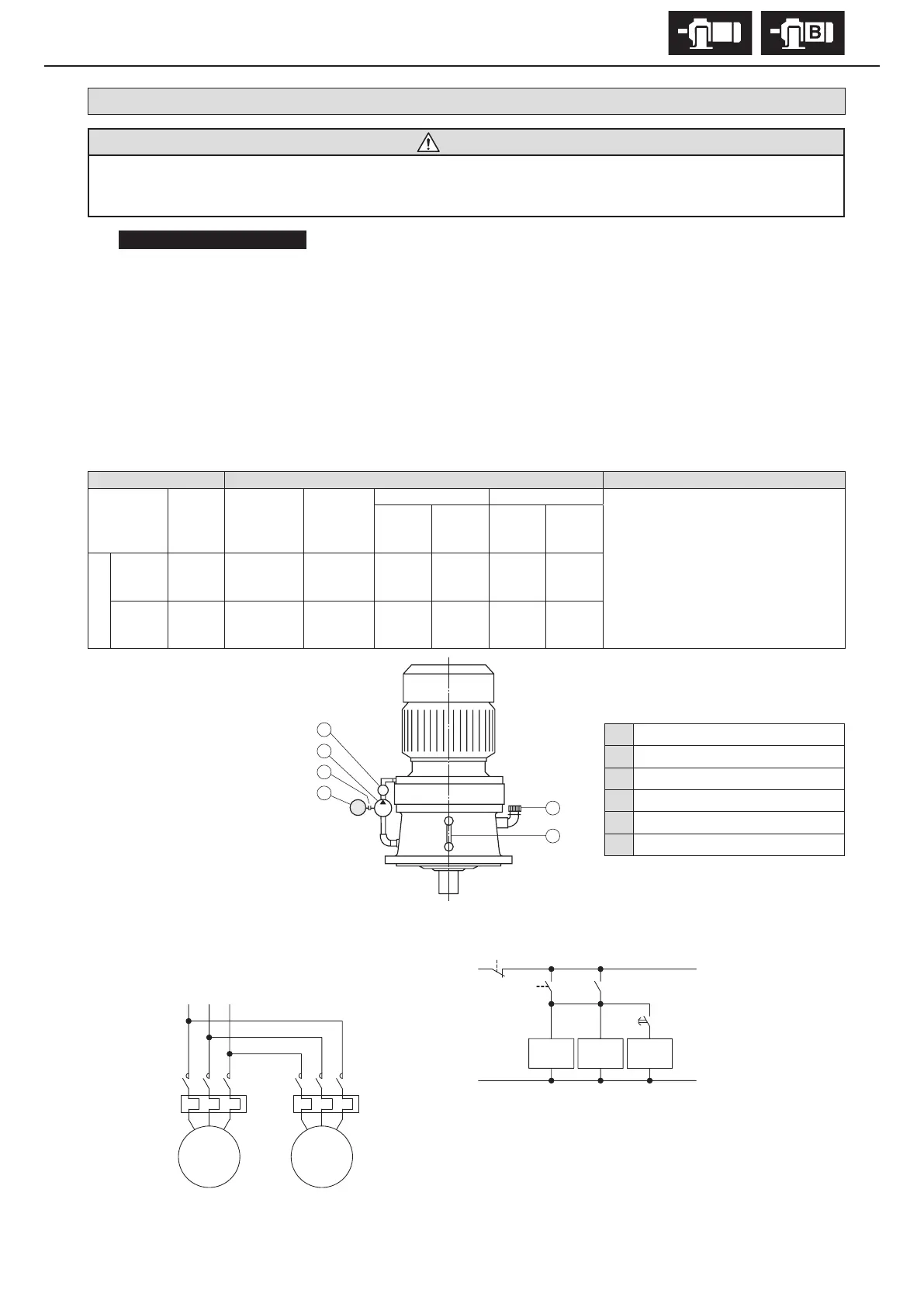

(2) For motorized trochoid pump wiring, see gure 6-5. Wire R-U, S-V, T-W. The pump motor rotates in the specied direction. (For

Japanese domestic standard specications. Consult with us for special specication, such as overseas specications and motors not

manufactured by Sumitomo.)

(3) Between the motor for the motorized trochoid pump and main motor, t with interlock that satises the following two functions. (See

gure 6-5)

[1] Start time: If the motorized trochoid pump does not activate, do not activate the main motor.

[2] While running: If for any reason the motorized trochoid pump stops, stop the main motor.

(4) To ensure good lubricating conditions, start (prime) the motorized trochoid pump at least 30 seconds before the main motor.

Table 6-5 Motorized Trochoid Pump Specications

Type Motorized trochoid pump Remarks

Frame size

Reduction

ratio

Pump

nomenclature

Pump motor

50 Hz region 60 Hz region

(1) Motorized trochoid pumps manufactured

by Nippon Oil Pump Co., Ltd. are used as

standard equipment.

(2) The motorized trochoid pump comes

standard with a release valve (set pressure

0.29 MPa).

Discharge

volume

(L/min)

Maximum

pressure

(MPa)

Discharge

volume

(L/min)

Maximum

pressure

(MPa)

Vertical

6275

Total

reduction

ratio

TOP-216HB-

VB-3

0.75kW 4P 24.0 0.78 28.8 0.49

6275DA

Total

reduction

ratio

TOP-204HB-

VB-3

0.4kW 4P 6.0 1.57 7.2 1.13

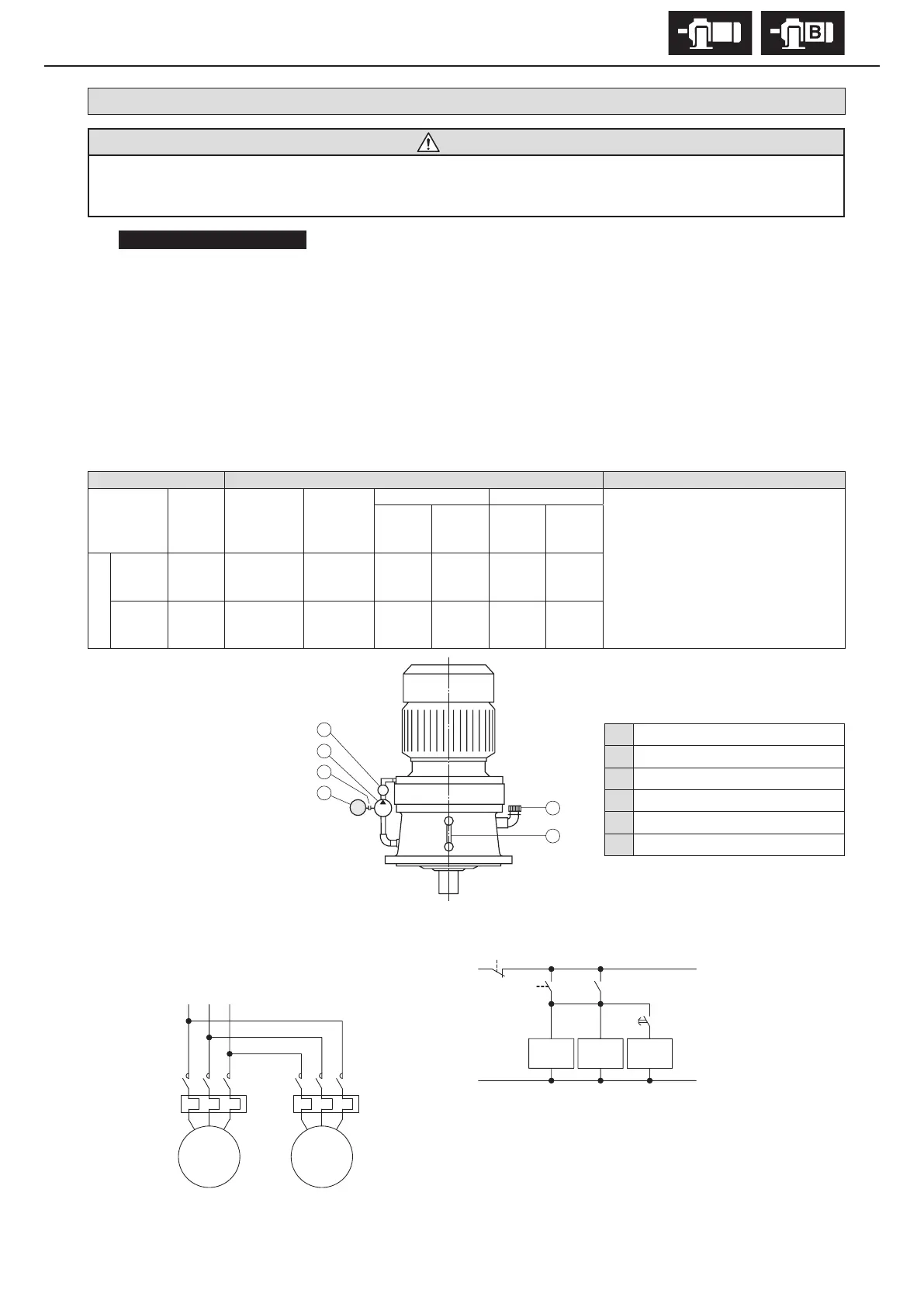

Figure 6-4 Structural diagram of machine with motorized trochoid pump

メインモータ

電動トロコイド

ポンプ用

モータ

OLROLR

MC2MC1

RS

電源

T

R1

PB2

S1

PB1 MC2

T

T

MC1MC2

a

b

c

d

e

f

M

a Flow sight

b Motorized trochoid pump

c Coupling

d Motor (for trochoid pump)

e Filler plug

f Oil gauge

Figure 6-5 Motorized trochoid pump circuit diagram

RS T

Power source

MC1

Main

Motor

Motor for

motorized

trochoid

pump

MC2

E

E

MC2 MC1T

R1

S1

MC1: Electromagnetic contactor (Main motor)

MC2: Electromagnetic contactor (Motor for motorized trochoid pump)

PB1: Push button switch (Start)

PB2: Push button switch (Stop)

T: Timer (30 or more seconds)

T

PB2PB1 MC2

OLR OLR

Loading...

Loading...