72-20-17 VALVE ROCKERS.

Worn bushing may be driven out with a suitable drift, and

if

properly

designed, the same tool may be used to drive in new bushings. The rocker must be supported

on a ring which will allow the old bushing to pass through. Press the new bushing in flush

with the rocker hub after dipping it in clean lubricating oil. Ream the new bushing to the

specified diameter reaming. It is advisable to plug the oil holes with beeswax before reaming,

but be sure to remove the wax afterwards.

Lightly break the sharp edge at each end. (Refer

to Figure 72-20-1 7).

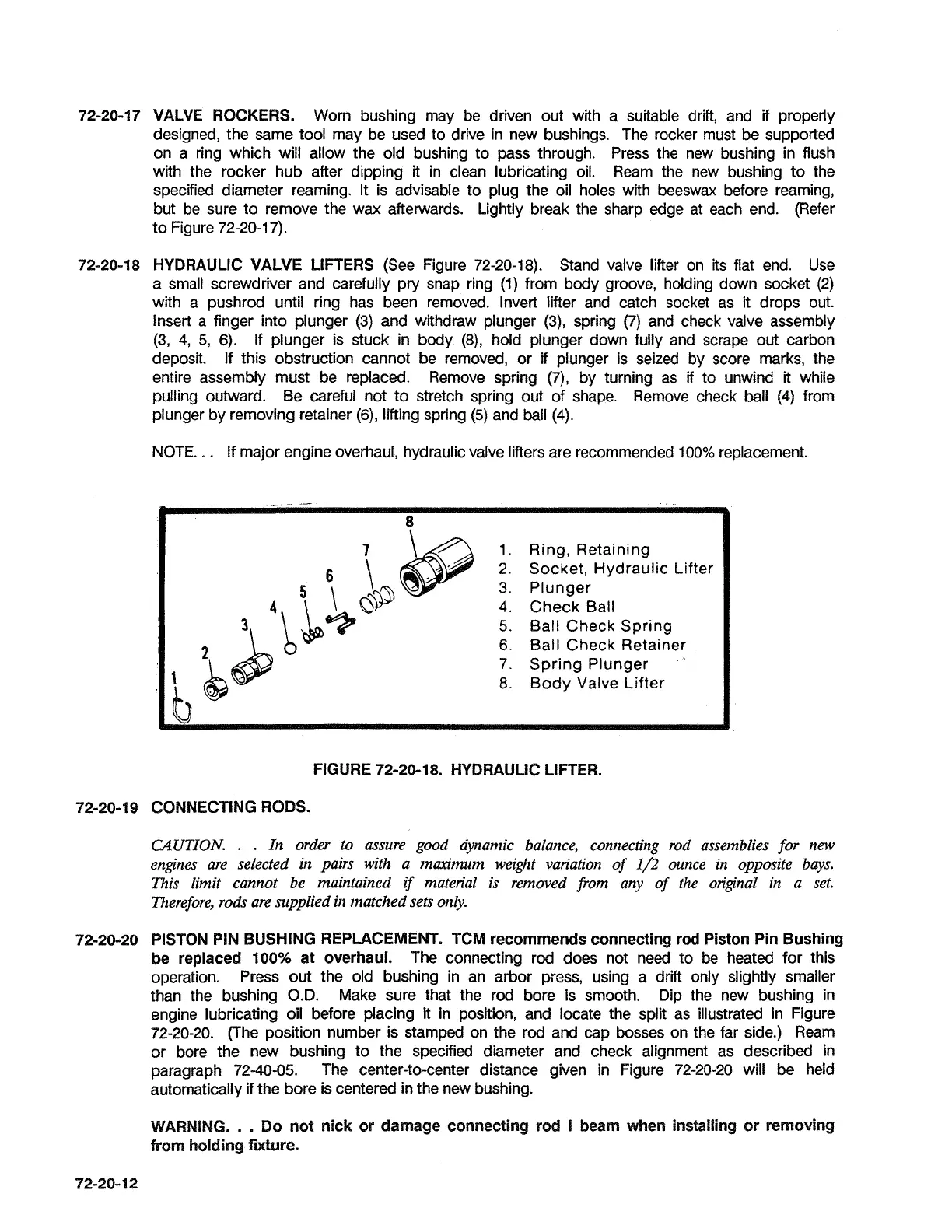

72-20-18 HYDRAULIC VALVE LIFTERS

(See Figure 72-20-18). Stand valve lifter on its flat end. Use

a small screwdriver and carefully pry snap ring (1) from body groove, holding down socket (2)

with a

pushrod until ring has been removed. Invert lifter and catch socket as

it

drops out.

Insert a finger into plunger (3) and withdraw plunger

(3), spring (7) and check valve assembly

(3,

4,

5,

6).

If plunger is stuck in body (8), hold plunger down fully and scrape out carbon

deposit. If this obstruction cannot be removed, or

if

plunger is seized by score marks, the

entire assembly must be replaced. Remove spring

(7), by turning as

if

to unwind

it

while

pulling outward. Be careful not to stretch spring out of shape. Remove check ball

(4)

from

plunger by removing retainer

(6),

lifting spring

(5)

and ball

(4).

NOTE.

. .

If major engine overhaul, hydraulic valve lifters are recommended 100% replacement.

Ring, Retaining

Socket, Hydraulic Lifter

Plunger

Check Ball

Ball Check Spring

Ball Check Retainer

Spring Plunger

Body Valve Lifter

FIGURE 72-20-1 8. HYDRAULIC LIFTER.

72-20-19 CONNECTING RODS.

CAUTION.

. .

In order to assure good dynamic balance, connecting rod assemblies for new

engines are selected in pairs with a

maximum weight variation of

1/2

ounce in opposite bays.

This

limit cannot be maintained

if

material is removed from any of the original in a set.

Therefore,

rodr are supplied in matched sets only.

72-20-20 PISTON PIN BUSHING REPLACEMENT. TCM recommends connecting rod Piston Pin Bushing

be replaced 100% at overhaul.

The connecting rod does not need to be heated for this

operation.

Press out the old bushing in an arbor press, using a drift only slightly smaller

than the bushing

O.D.

Make sure that the rod bore is smooth. Dip the new bushing in

engine lubricating oil before placing it in position, and locate the split as illustrated in Figure

72-20-20.

(The position number is stamped on the rod and cap bosses on the far side.) Ream

or bore the new bushing to the specified diameter and check alignment as described in

paragraph 72-40-05. The center-to-center distance given in Figure 72-20-20 will be held

automatically

if

the bore is centered in the new bushing.

WARNING.

.

.

Do not nick or damage connecting rod

I

beam when installing or removing

from holding fixture.

Loading...

Loading...