70-20-00

PERMATEX, THREADING PROCEDURE AND GASKET MAKER

1.

Use full strength non-thinned Permatex aviation grade 3D. Shake or mix well before

using.

2.

Apply

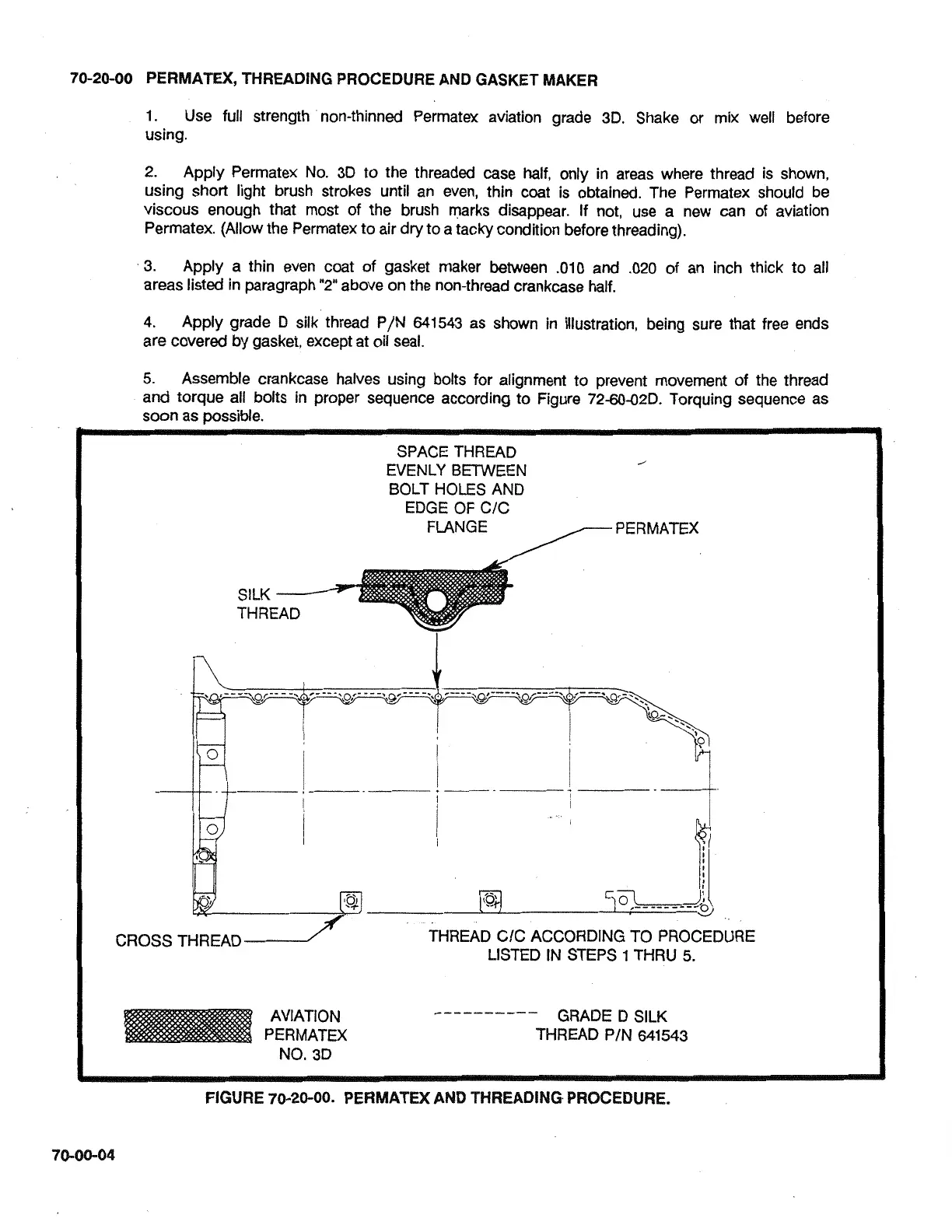

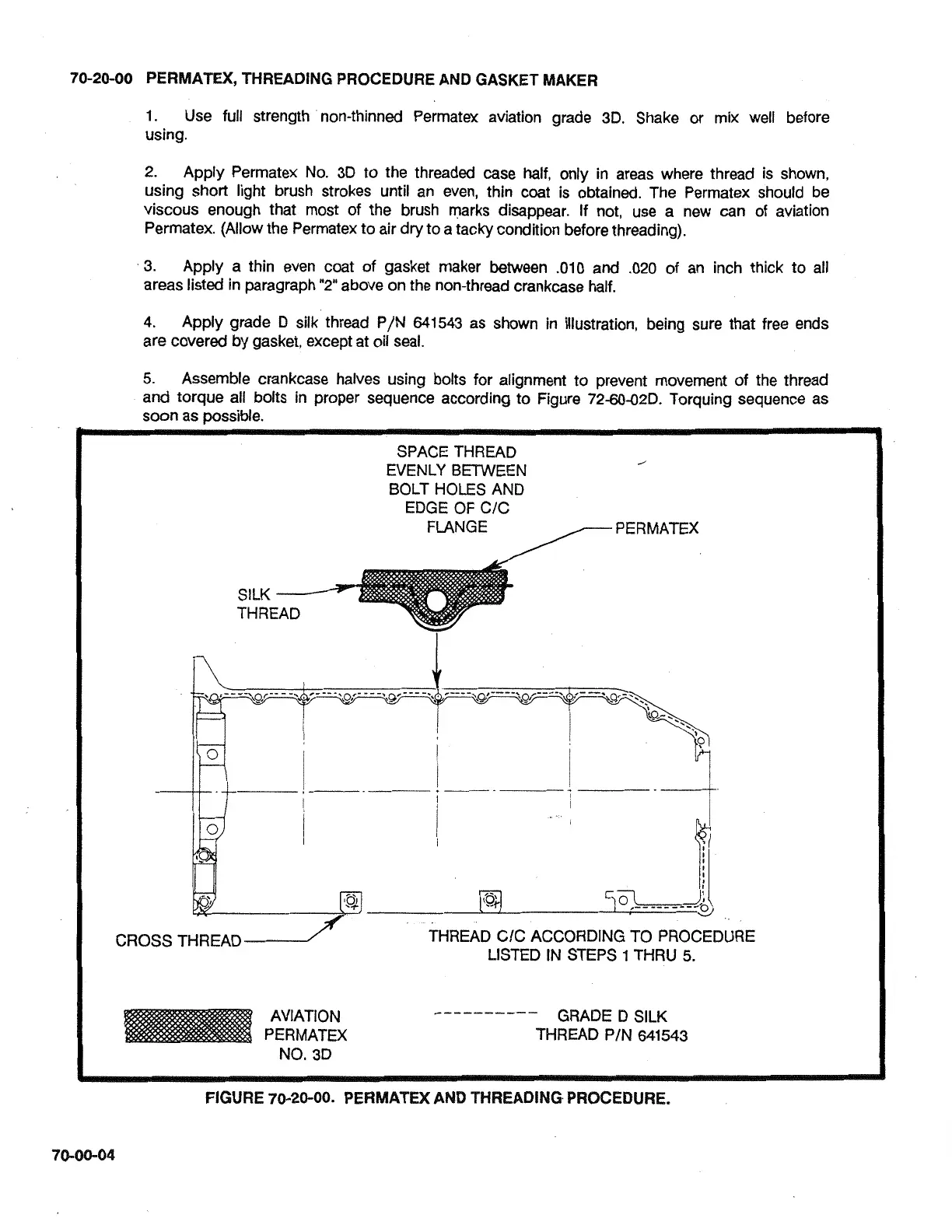

Permatex No. 3D to the threaded case half, only in areas where thread is shown,

using short light brush strokes until an even, thin coat is obtained. The

Permatex should be

viscous enough that most of the brush marks disappear. If not, use a new can of aviation

Permatex. (Allow the

Permatex to air dry to a tacky condition before threading).

3.

Apply a thin even coat of gasket maker between

.010

and .020 of an inch thick to all

areas listed in paragraph "2" above on the non-thread crankcase half.

4.

Apply grade D silk thread P/N

641543

as shown in illustration, being sure that free ends

are covered by gasket, except at oil seal.

5.

Assemble crankcase halves using bolts for alignment to prevent movement of the thread

and torque all bolts in proper sequence according to Figure

726002D. Torquing sequence as

soon as

~ssiMe.

SPACETHREAD

EVENLY BETWEEN

1

BOLT HOLES AND

EDGE OF

CIC

.-.

CROSS THREAD

THREAD

CIC ACCORDING TO PROCEDURE

LISTED IN STEPS

1

THRU

5.

AVIATION

----------

GRADE D SILK

PERMATEX THREAD PIN

641543

NO. 3D

FIGURE

70-20-00.

PERMATEX AND THREADING PROCEDURE.

Loading...

Loading...