70-50-03

PERFORMING

THE

CHECK

The following procedures are listed to outline the prii-lciples involved, and are intended to

supplement the manufacturer's instructions for the particular tester being utilized.

WARNING

. .

.

Magnetos and fuel must be shut off prior to test to make certain that the

engine cannot accidentally fire.

(a) Perform the test as soon as possible after the engine is shut down to ensure that the

piston rings,

cylinder walls, and other engine parts are well lubricated and at running

tolerance.

(b) Remove the most accessible spark plug from each cylinder.

(c) Turn the crankshaft by hand in the direction of rotation until the piston (in the cylinder

being checked) is coming up on its compression stroke.

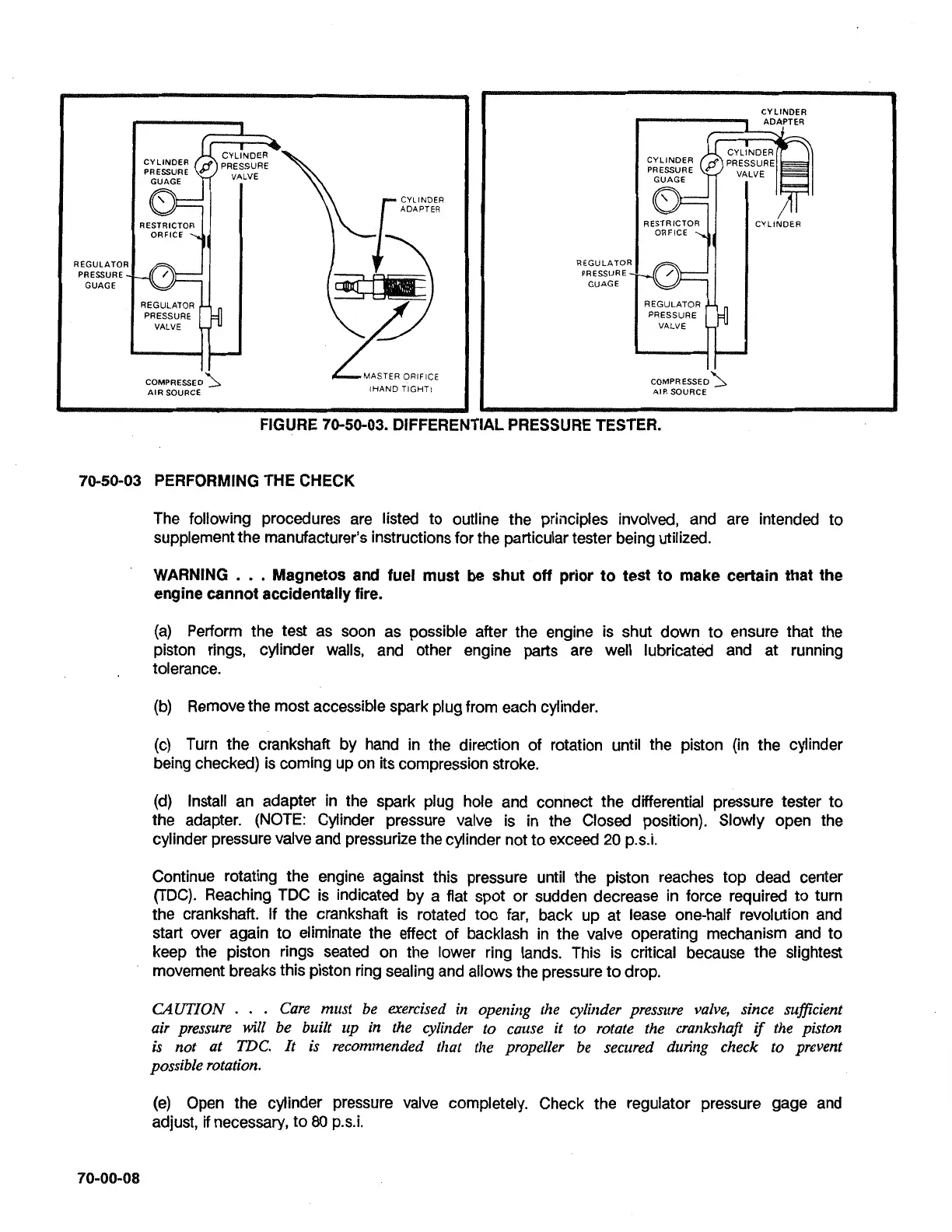

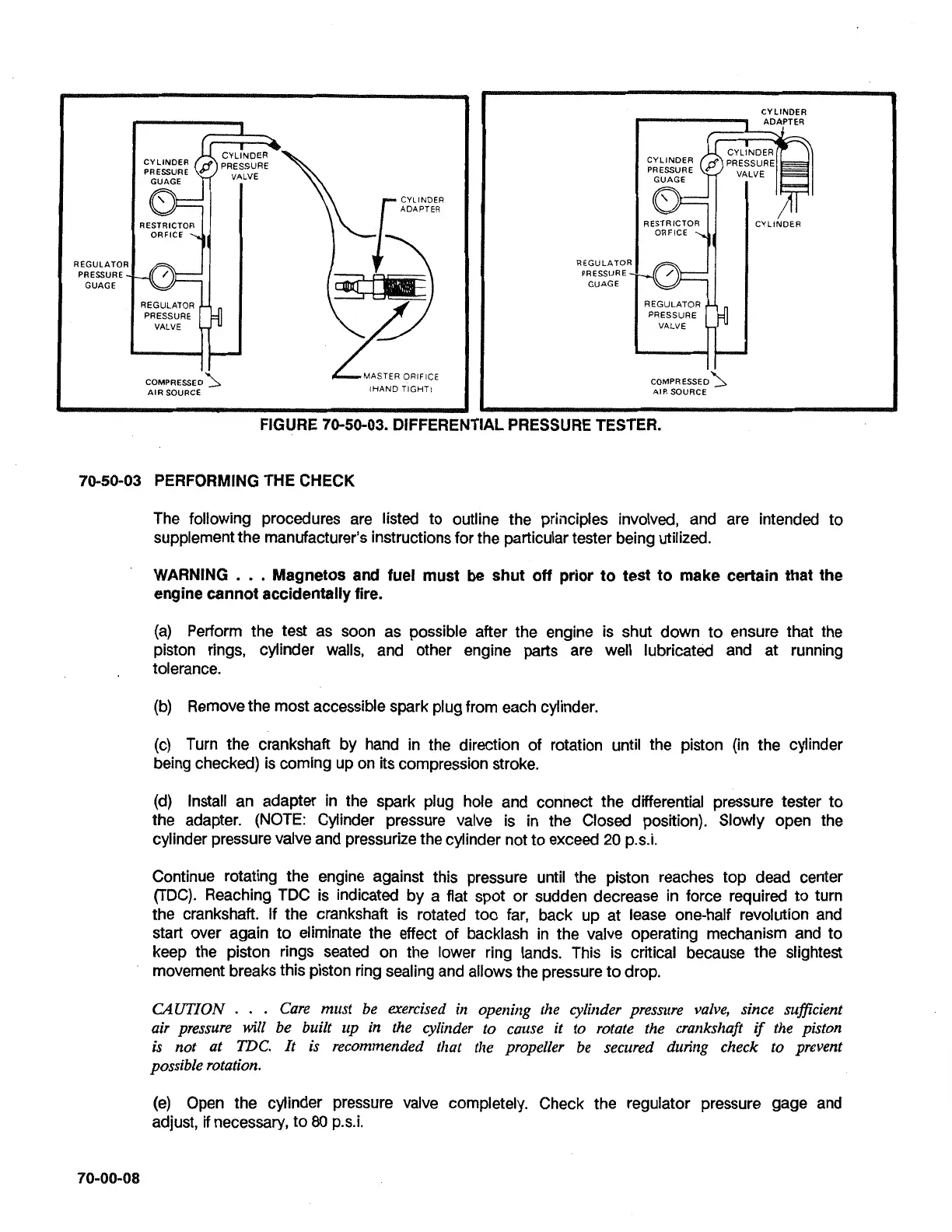

(d) Install an adapter in the spark plug hole and connect the differential pressure tester to

the adapter.

(NOTE:

Cylinder pressure valve is in the Closed position). Slowly open the

cylinder pressure valve and pressurize the cylinder not to exceed

20

p.s.i.

Continue rotating the engine against this pressure until the piston reaches top dead center

(TDC). Reaching TDC is indicated by a flat spot or sudden decrease in force required to turn

the crankshaft. If the crankshaft is rotated too far, back up at lease one-half revolution and

start over again to eliminate the effect of backlash in the valve operating mechanism and to

keep the piston rings seated on the lower ring lands. This is criiical because the slightest

movement breaks this piston ring sealing and allows the pressure to drop.

GlUTION

.

. .

Care must be exercised in opeiting the cylinder pressure valve, since sufficient

air pressure will be built

up in the cylinder to cause it to rotate the crattksltaft

if

the piston

is not at TDC. It is recommended that

the propeller be secured

drlri~zg

check to prevent

possible rotation.

(e) Open the cylinder pressure valve completely. Check the regulator pressure gage and

adjust,

if

necessary, to

80

p.s.i.

Loading...

Loading...