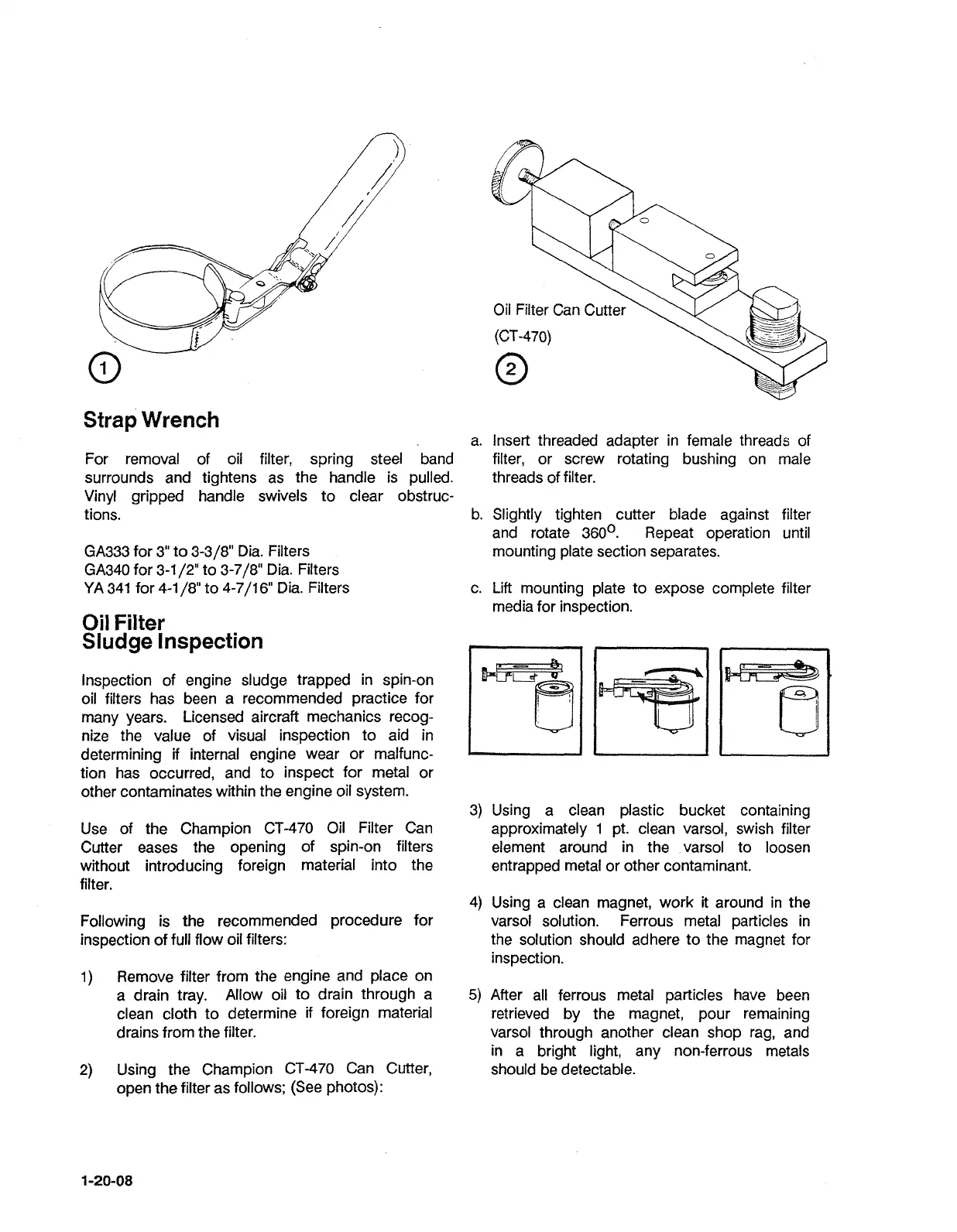

Strap Wrench

For removal of oil filter, spring steel band

surrounds and tightens as the handle is pulled.

Vinyl gripped handle swivels to clear obstruc-

tions.

GA333 for 3" to 3-3/8" Dia. Filters

GA340 for 3-1

/2"

to 3-7/8" Dia. Filters

YA 341 for 4-1

/8" to 4-7/16 Dia. Filters

Oil

Filter

Sludge lnspection

lnspection of engine sludge trapped in spin-on

oil filters has been a recommended practice for

many years. Licensed aircraft mechanics recog-

nize the value of visual inspection to aid in

determining

if

internal engine wear or malfunc-

tion has occurred, and to inspect for metal or

other contaminates within the engine oil system.

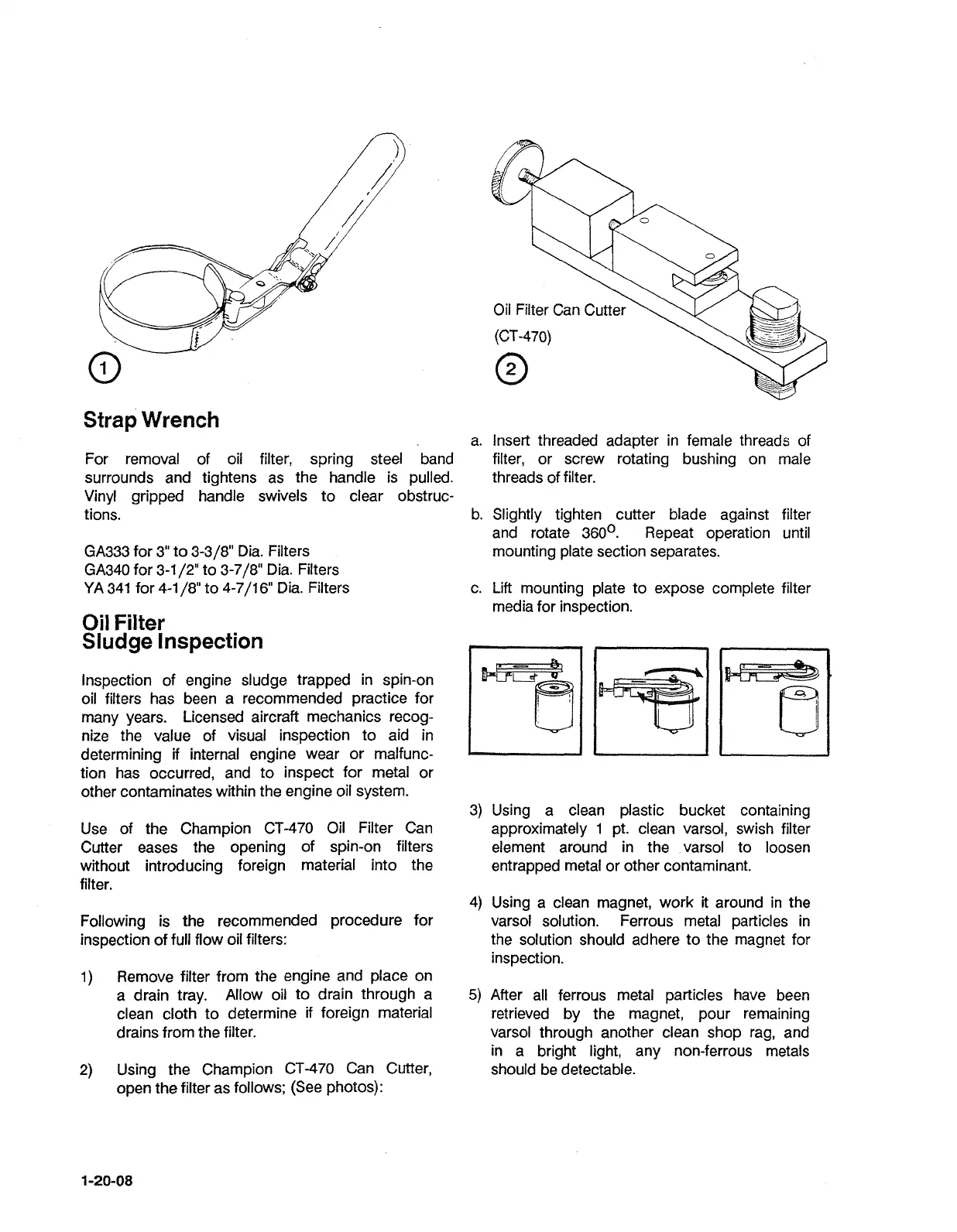

Use of the Champion CT-470 Oil Filter Can

Cutter eases the opening of spin-on filters

without introducing foreign material into the

filter.

Following is the recommended procedure for

inspection of full flow oil filters:

a. Insert threaded adapter in female threads of

filter, or screw rotating bushing on male

threads of filter.

b. Slightly tighten cutter blade against filter

and rotate

360°. Repeat operation until

mounting plate section separates.

c. Lift mounting plate to expose complete filter

media for inspection.

3) Using a clean plastic bucket containing

approximately 1 pt. clean varsol, swish filter

element around in the varsol to loosen

entrapped metal or other contaminant.

4) Using a clean magnet, work it around in the

varsol solution. Ferrous metal

particles in

the solution should adhere to the magnet for

inspection.

1)

Remove filter from the engine and place on

a drain tray. Allow oil to drain through a

5)

After all ferrous metal particles have been

clean cloth to determine if foreign material retrieved by the magnet, pour remaining

drains from the filter.

varsol through another clean shop rag, and

in a bright light, any non-ferrous metals

2)

Using the Champion CT-470 Can Cutter, should be detectable.

open the filter as follows; (See photos):

Loading...

Loading...