(SLICK IGNITION SYSTEM)

74-10-00 GENERAL

Conventional dual ignition is provide by two magnetos. The left magneto fires the six

(6)

upper spark plugs, while the right magneto fires the six

(6)

lower spark plugs.

The Slick

6214

Series Magnetos, manufactured by Slick Electro Incorporated,

530

Blackhawk

Park Avenue, Rockford, Illinois

61101,

are designed to provide ignition for six cylinder light

aircraft engines. The magnetos generate and distribute high tension current through high

tension leads to the spark plugs.

To obtain the retard spark necessary for starting, the magnetos employ an impulse coupling.

The purpose of the impulse coupling is to:

(1)

rotate the magnet between impulse trips faster

than engine cranking speed, thus generating a better spark for starting the engine;

(2)

automatically retard the spark during engine cranking, and

(3)

act as a drive coupling for the

magneto.

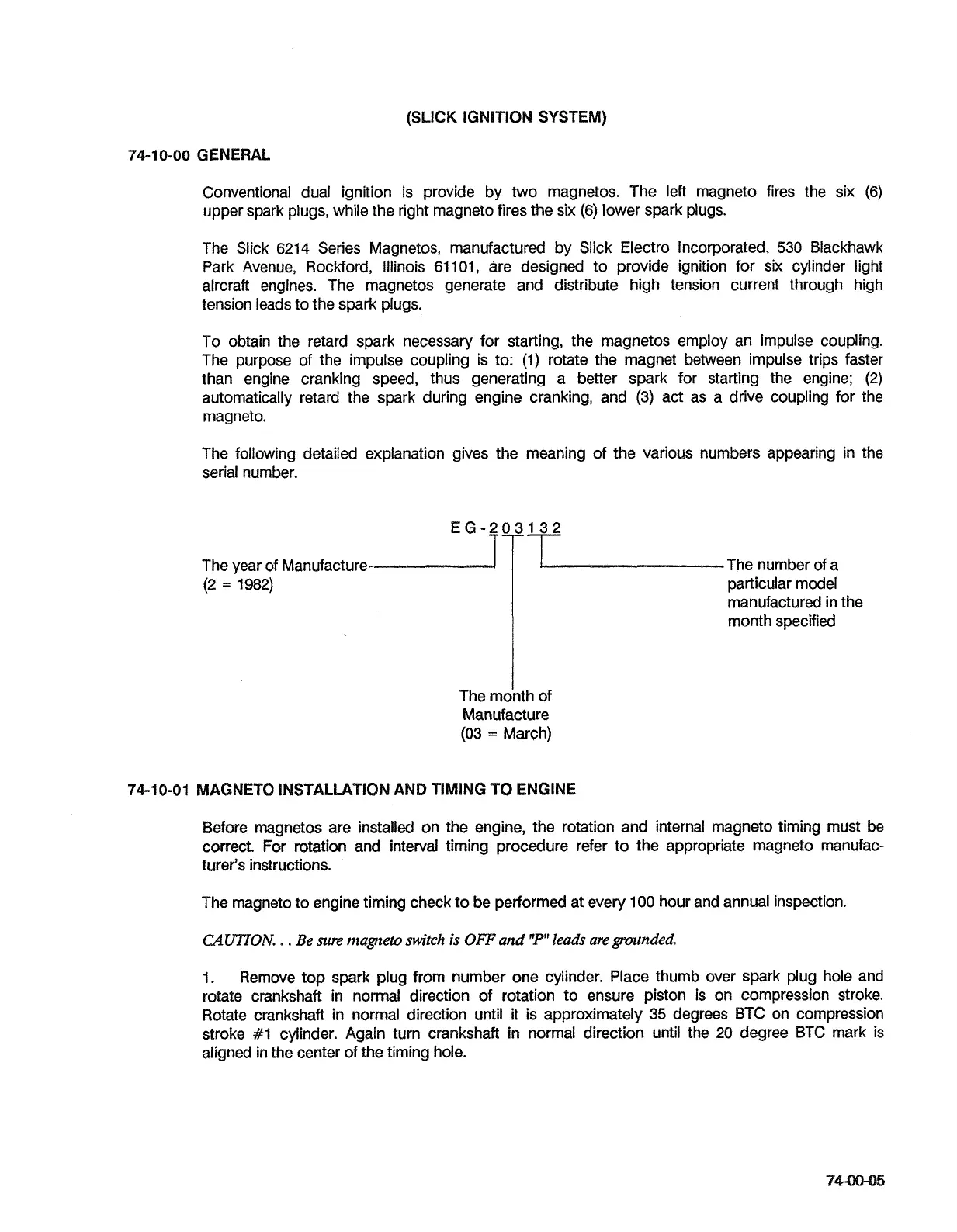

The following detailed explanation gives the meaning of the various numbers appearing in the

serial number.

EG-203132

The year of Manufacture-

The number of a

(2

=

1982)

particular model

manufactured in the

m~nth specified

The month of

Manufacture

(03

=

March)

74-10-01 MAGNETO INSTALWWON AND TIMING TO ENGINE

Before magnetos are installed on the engine, the rotation and internal magneto timing must be

correct. For rotation and interval timing procedure refer to the appropriate magneto manufac-

turer's instructions.

The magneto to engine timing check to be performed at every

100

hour and annual inspection.

G1UTION.

-

..

Be sure magneto

switch

is

OFF

and

'7"'

lea& are grounded.

1.

Remove top spark plug from number one cylinder. Place thumb over spark plug hole and

rotate crankshaft in normal direction of rotation to ensure piston is on compression stroke.

Rotate crankshaft in normal direction until it is approximately

35

degrees

BTC

on compression

stroke

#I

cylinder. Again turn crankshaft in normal direction until the

26

degree BTC mark is

aligned in

the center of the timing hole.

Loading...

Loading...