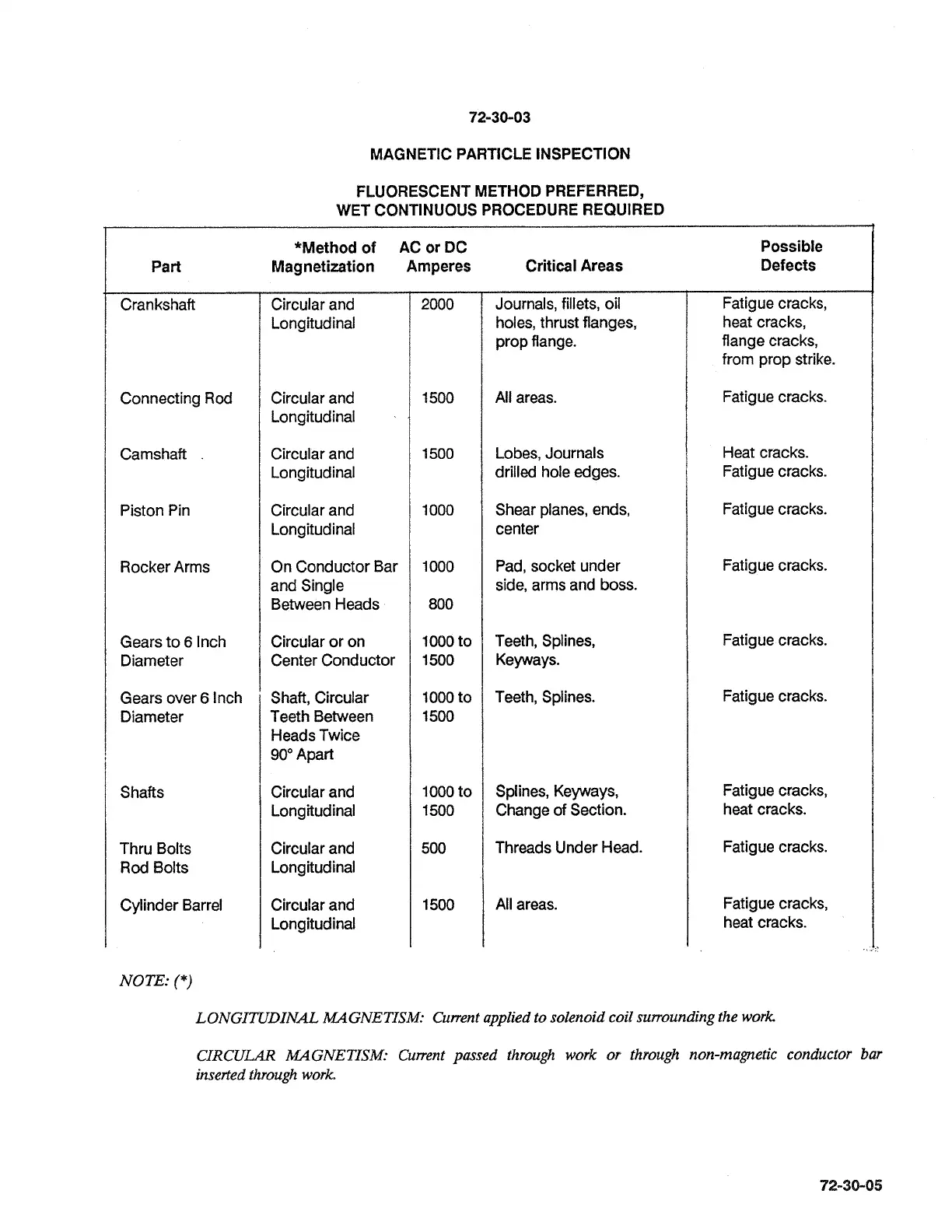

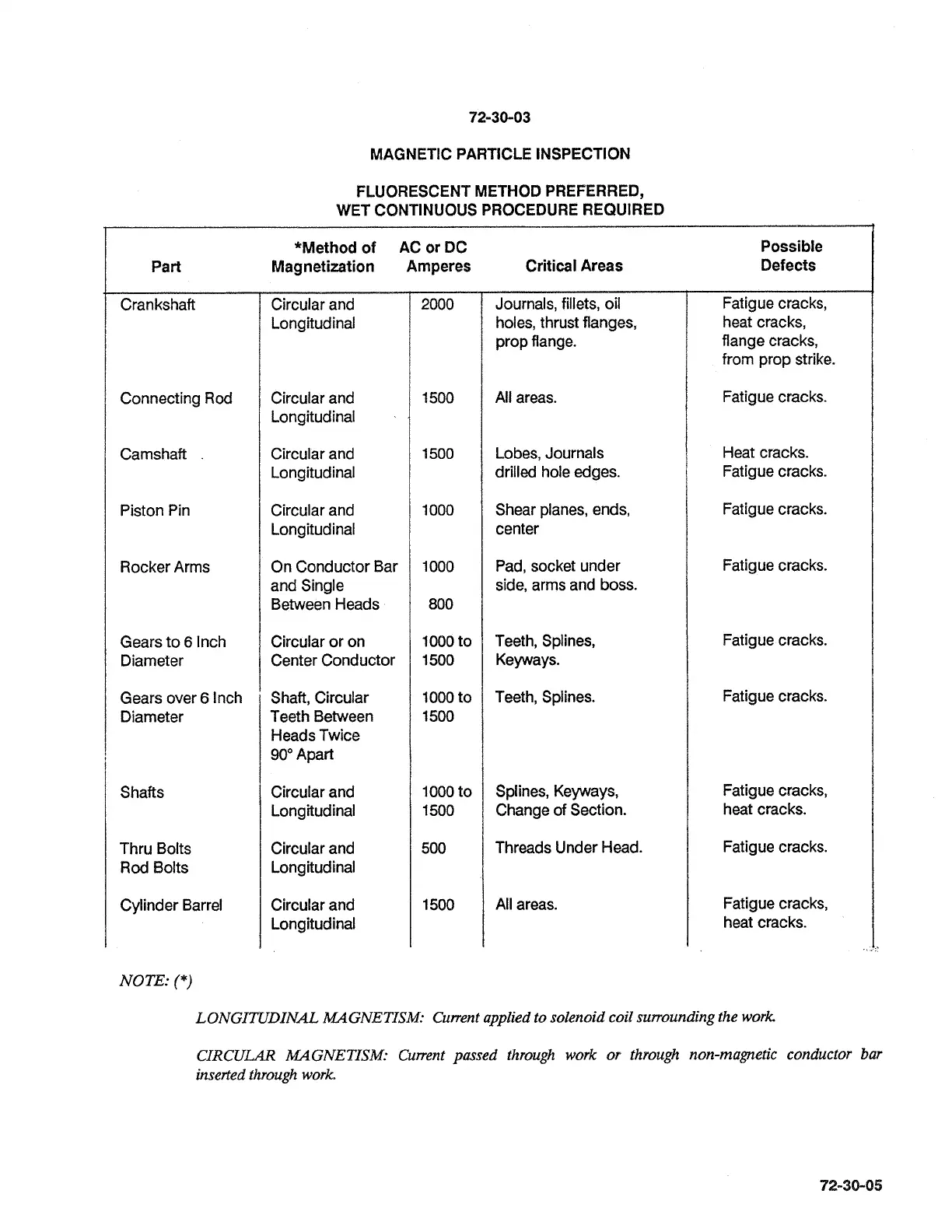

MAGNETIC PARTICLE INSPECTION

FLUORESCENT METHOD PREFERRED,

WET CONTINUOUS PROCEDURE REQUIRED

*Method of AC or DC

Part Magnetization Amperes

Crankshaft Circular and

Longitudinal

Connecting

Rod

Camshaft

Piston Pin

Rocker Arms

Gears to

6

lnch

Diameter

Gears over

6

lnch

Diameter

Shafts

Thru Bolts

Rod

Bolts

Cylinder Barrel

Circular and

Longitudinal

Circular and

Longitudinal

Circular and

Longitudinal

On Conductor Bar

and Single

Between Heads

Circular or on

Center Conductor

Shaft, Circular

Teeth Between

Heads Twice

90"

Apart

Circular and

Longitudinal

Circular and

Longitudinal

Circular and

Longitudinal

Critical Areas

Journals, fillets, oil

holes, thrust flanges,

prop flange.

All areas.

Lobes, Journals

drilled hole edges.

Shear planes, ends,

center

Pad, socket under

side, arms and boss.

Teeth, Splines,

Keyways.

Teeth, Splines.

Splines, Keyways,

Change of Section.

Threads Under Head.

All areas.

Possible

Defects

Fatigue cracks,

heat cracks,

flange cracks,

from prop strike.

Fatigue cracks.

Heat cracks.

Fatigue cracks.

Fatigue cracks.

Fatigue cracks.

Fatigue cracks.

Fatigue cracks.

Fatigue cracks,

heat cracks.

Fatigue cracks.

Fatigue cracks,

heat cracks.

NOTE:

(*)

LONGITUDINAL MAGNETISM: Current applied to solenoid coil surrounding the work

CIRCULAR MAGNETISM: Current passed through work or through non-magnetic conductor bar

inserted through work.

Loading...

Loading...