- 7 -

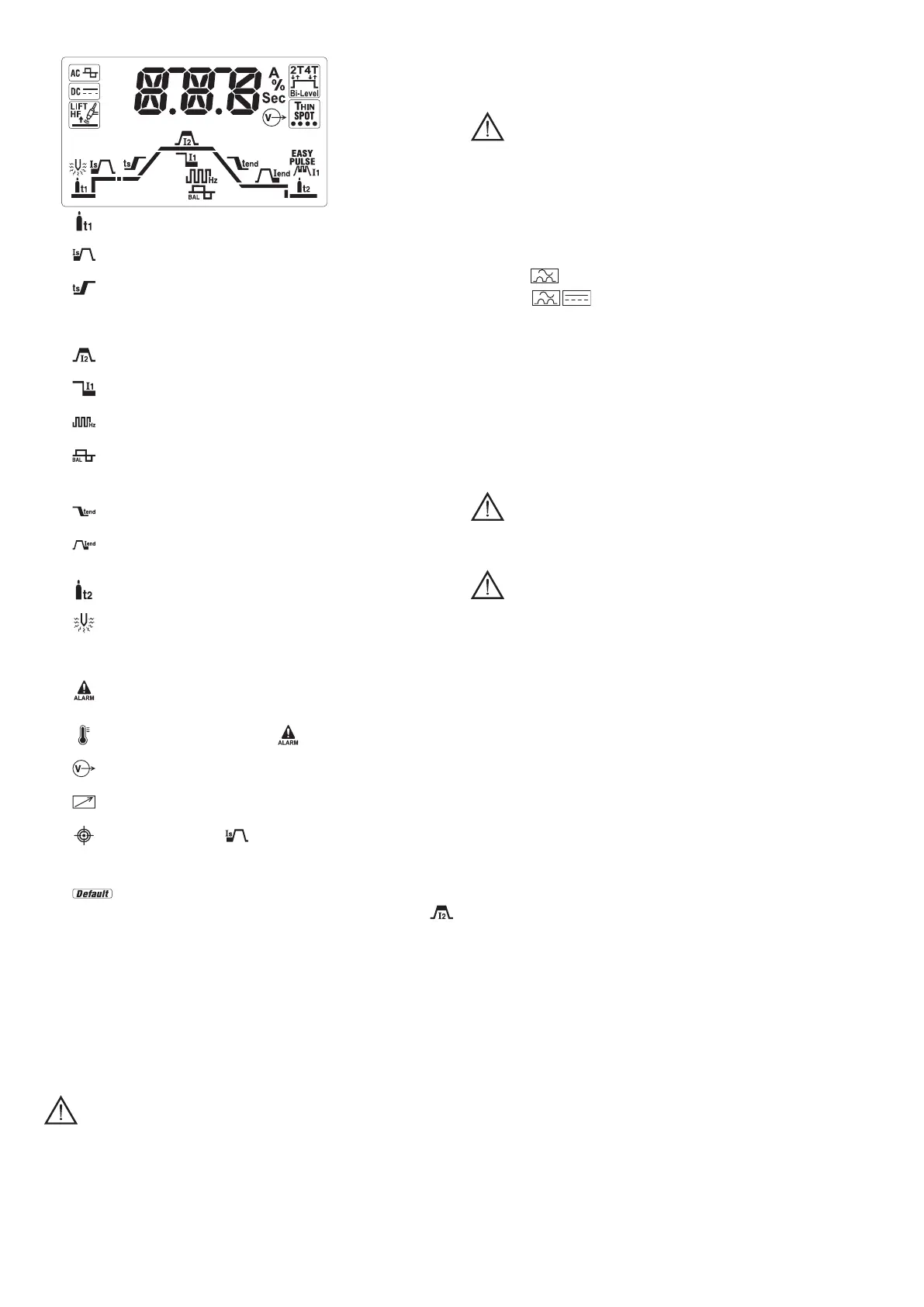

Inparticular,inTIG,theparametersthatcanbechangedare:

- pre-gas time of safety gas ow before starting welding (0-10 seconds

adjustment).

-

initial current maintained for a set time in 2T (50msec) and for the time the

push-button is pressed, in 4T (0-100% adjustment).

-

initial ramp time of the current from value I

s

to I

2

(0.1-10 seconds

adjustment). In OFF ramp not present.

N.B.: parameters I

s

and T

s

can also be modied with the pedal remote

command. Adjustment, however, must be made before activating the

commanditself.

-

main welding current, in PULSED and Bi-Level mode is the current at

higher level (output current in Amperes).

-

basic current, in PULSED and Bi-Level mode is the value which can be

alternated with the main one during welding (adjustment in Amperes).

-

pulsation frequency and for AC/DC models in TIG AC it represents the

frequency of the welding current (adjustment in Hertz).

-

balance percentage, in PULSED mode is the ratio between the time in

which the current is at the highest level and the total pulsation period, for AC/DC

models in TIG AC it represents the ratio between the time with positive current

and the time with negative current.

-

nal ramp time of the current from value I

2

to I

end

(0.1-10 seconds

adjustment). In OFF ramp not present.

-

nal current, in 2T it is the current maintained after the nal ramp if the

ramp time is over zero, in 4T it is the current maintained after the nal ramp for

the entire time in which the torch push-button remains pressed.

-

post-gas time of safety gas ow starting from welding stoppage (0-10

seconds adjustment).

-

pre-heating energy, if installed, only for AC/DC models in TIG AC adjusts

pre-heating of the electrode to facilitate start-up (2.6-53 A*Sec adjustment). In

OFF pre-heating not present.

Otherexplanatoryiconsonthedisplay:

-

warning/alarm, in general combined with the code indicated on the display,

drawing attention to possible anomalies/automatic protection activated on the

welding machine.

-

thermal protection, combined with and the code on the display,

warning the condition of internal heating limits has been reached.

-

active output, indicates voltage is present (power enabled) in the output

sockets of the welding machine.

-

remote command, indicates connection and control is active on the remote

command.

-

position pointer, in 4T with under a preset value, it indicates setting of

a minimum initial current that makes the welding arc visible with push-button

pressed. This allows precise selection of the starting point of the welding (if the

initial current is set beyond a certain limit the function automatically disables).

-

factory parameters, indicates setting of all the parameters at a preset

value useful for wide-ranging operativity. The user can set the main current

as wished to alter the other automatic settings.

It is possible to re-activate this condition at any time by switching off and back on

the welding machine with the push-button on the multi-function knob (FIG. D - 5c)

pressed.

Explanatoryalarmmessagesonthealphanumericaldisplay(FIG.D-5d):

- AL.1 : the primary circuit protection thermal switch has been triggered (if

installed).

- AL.2 : the secondary circuit protection thermal switch has been triggered.

- AL.3 : power line overvoltage protection has been triggered.

- AL.4 : power line undervoltage protection has been triggered.

- AL.8 : auxiliary voltage out of range.

Resetting is automatic when the reason for alarm activation stops.

5.INSTALLATION

WARNING! CARRY OUT ALL INSTALLATION OPERATIONS AND

ELECTRICAL CONNECTIONS WITH THE WELDING MACHINE COMPLETELY

SWITCHEDOFFANDDISCONNECTEDFROMTHEPOWERSUPPLYOUTLET.

THEELECTRICALCONNECTIONS MUSTBEMADEONLYANDEXCLUSIVELY

BYAUTHORISEDORQUALIFIEDPERSONNEL.

5.1PREPARATION(FIG.P)

Unpack the welding machine, assemble the separate parts contained in the package.

5.1.1Assemblingthereturncable-clamp(FIG.E)

5.1.2Assemblingtheweldingcable-electrodeholderclamp(FIG.E)

5.2POSITIONOFTHEWELDINGMACHINE

Choose the place to install the welding machine so that the cooling air inlets and

outlets are not obstructed (forced circulation by fan, if present); at the same time make

sure that conductive dusts, corrosive vapours, humidity etc. will not be sucked into

the machine.

Leave at least 250mm free space around the welding machine.

WARNING! Position the welding machine on a at surface with

sufcientcarryingcapacityforitsweight,topreventitfromtippingormoving

hazardously.

5.3CONNECTIONTOTHEMAINPOWERSUPPLY

- Before making any electrical connection, make sure the rating data of the welding

machine correspond to the mains voltage and frequency available at the place of

installation.

- The welding machine should only be connected to a power supply system with the

neutral conductor connected to earth.

- To ensure protection against indirect contact use residual current devices of the

following types:

- Type A (

) for single phase machines;

- Type B (

) for 3-phase machines.

- In order to satisfy the requirements of the EN 61000-3-11 (Flicker) standard we

recommend connecting the welding machine to the interface points of the main

power supply that have an impedance of less than:

Zmax = 0.234 Ohm (1/N/PE 230V) 200A DC

- The IEC/EN 61000-3-12 Standard does not apply to the welding machine.

If the welding machine is connected to an electrical grid, the installer or user must

make sure that the machine can indeed be connected (if necessary, consult the

company that manages the electrical grid).

5.3.1Plugandoutlet

Connect a normalised plug (2P + P.E) (1~); (3P + P.E) (3~) - having sufcient capacity-

to the power cable and prepare a mains outlet tted with fuses or an automatic circuit-

breaker; the special earth terminal should be connected to the earth conductor (yellow-

green) of the power supply line. Table (TAB.1) shows the recommended delayed fuse

sizes in amps, chosen according to the max. nominal current supplied by the welding

machine, and the nominal voltage of the main power supply.

WARNING!Failuretoobservetheaboveruleswillmakethe(Class1)

safetysysteminstalledbythemanufacturerineffectivewithconsequentserious

riskstopersons(e.g.electricshock)andobjects(e.g.re).

5.4CONNECTIONOFTHEWELDINGCABLES

WARNING!BEFOREMAKINGTHEFOLLOWINGCONNECTIONSMAKE

SURETHEWELDINGMACHINEISSWITCHEDOFFANDDISCONNECTEDFROM

THEPOWERSUPPLYOUTLET.

Table (TAB. 1) gives the recommended values for the welding cables (in mm

2

)

depending on the maximum current supplied by the welding machine.

5.4.1TIGwelding

Connectingthetorch

- Insert the torch current cable into the appropriate quick terminal (-). Connect the

three-pin connector (torch button) to the appropriate socket. Connect the torch gas

pipe to the appropriate connector.

Connectingtheweldingcurrentreturncable

- This is connected to the piece to be welded or to the metal bench on which it rests,

as close as possible to the joint being made.

This cable is connected to the terminal with the (+) symbol.

Connectingthegasbottle

- Screw the pressure reducing valve to the gas bottle valve, rst inserting the special

reduction accessory supplied when argon gas is used.

- Connect the gas inow hose to the pressure reducing valve and tighten the hose

clamp supplied.

- Loosen the ringnut for adjusting the pressure reducing valve before opening the

valve on the bottle.

- Open the valve on the bottle and adjust the quantity of gas (l/min) according to the

suggestions for use given in the table (TAB.4); if it is necessary to adjust the gas

ow during welding this should always be done by adjusting the ring nut on the

pressure reduction valve. Make sure there are no leaks in the piping and connectors.

WARNING!Alwaysclosethegasbottlevalveattheendofthejob.

5.4.2MMAWELDING

Almost all coated electrodes are connected to the positive pole (+) of the power

source; as an exception to the negative pole (-) for acid coated electrodes.

Connectingtheelectrode-holderclampweldingcable

On the end take a special terminal that is used to close the uncovered part of the

electrode.

This cable is connected to the terminal with the symbol (+)

Connectingtheweldingcurrentreturncable

This is connected to the piece being welded or to the metal bench supporting it, as

close as possible to the join being made.

This cable is connected to the terminal with the symbol (-)

Warnings:

- Turn the welding cable connectors right down into the quick connections (if present),

to ensure a perfect electrical contact; otherwise the connectors themselves will

overheat, resulting in their rapid deterioration and loss of efciency.

- The welding cables should be as short as possible.

- Do not use metal structures which are not part of the workpiece to substitute the

return cable of the welding current: this could jeopardise safety and result in poor

welding.

6.WELDING:DESCRIPTIONOFTHEPROCEDURE

6.1TIGWELDING

TIG welding is a welding procedure that exploits the heat produced by the electric arc

that is struck, and maintained, between a non-consumable electrode (tungsten) and

the piece to be welded. The tungsten electrode is supported by a torch suitable for

transmitting the welding current to it and protecting the electrode itself and the weld

pool from atmospheric oxidation, by the ow of an inert gas (usually argon: Ar 99.5)

which ows out of the ceramic nozzle (FIG.G).

To achieve a good weld it is absolutely necessary to use the exact electrode diameter

with the exact current, see the table (TAB.3).

The table on the covering of the machine suggests the approximate current values to

use in the various material thicknesses with reference to DC welding of mild steel or

Loading...

Loading...