LLZ 421

Operation and Maintenance Maintenance

ILS 420

6−5Ed. 01.10

SOAC

6.2.4.1 Performing advanced Check of MIT Function (ECU 120571−0003 only)

With the ECU 120571−0003 an advanced check of the MIT−Function is introduced. This check must

not be performed with the ECU −0001 and −0002. The MIT check in section 6.2.4 can be performed

for both the ECU −0001/−0002 and the ECU −0003.

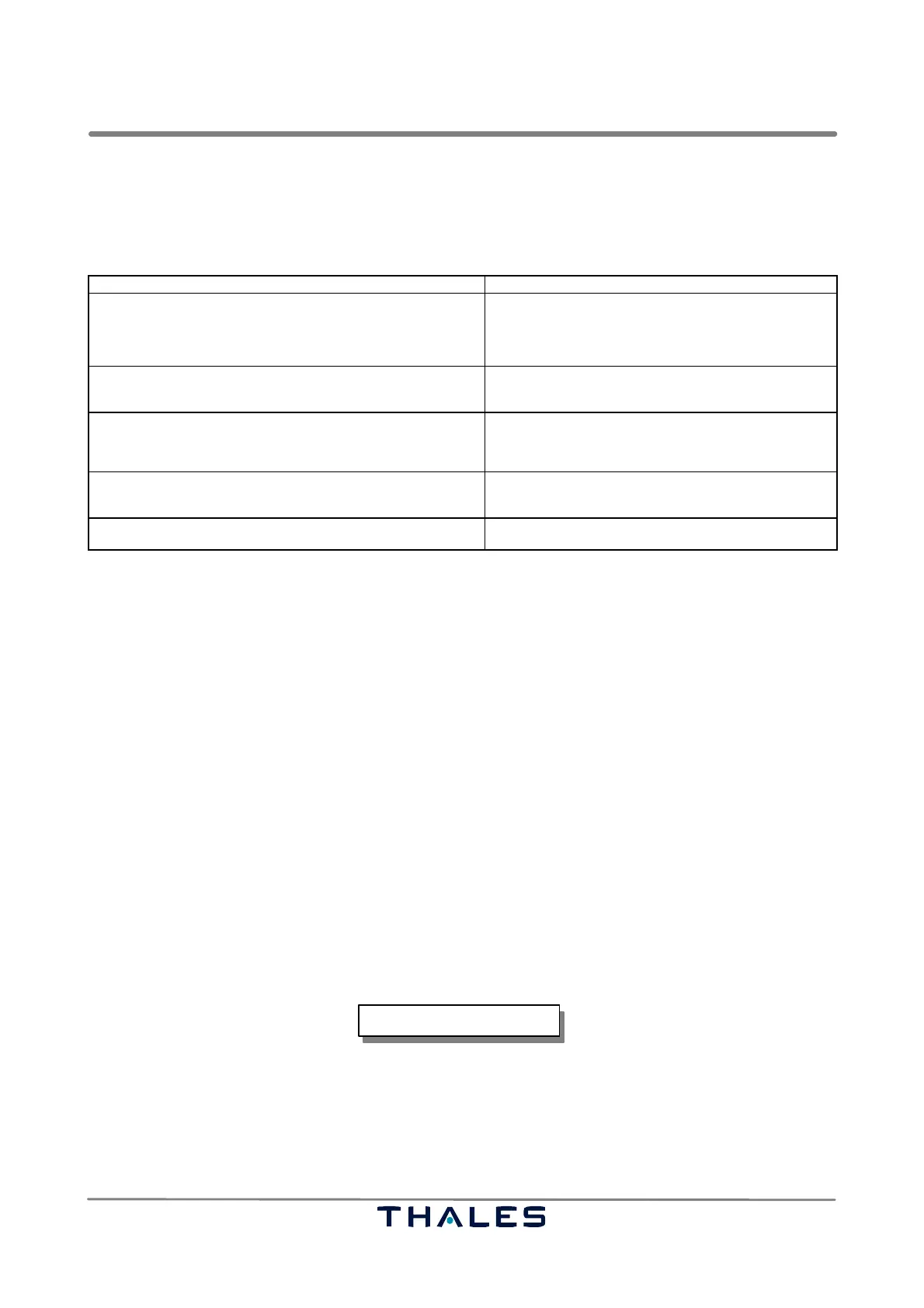

Test action Expected result

Verify monitor bypass off; key switch is in ’Remote’ or ’Local’ position.

− Open dialog ’TX Integrity Test Waveforms’ for the transmitter that is

on aerial (e.g. TX1), and that is on Standby (e.g. TX2).

− Open dialog ’Integrity Test Data’ for monitor 1 and monitor 2.

− Open dialog ’LRCI System Status’.

Verify all reading in normal conditions.

Change ’Integrity test signal A DDM’ (TX1/ LGA1)

from 0.0 % DDM to 1.5 % DDM.

Verify changeover of TX1 aerial to TX2 standby, now aerial.

Check at ECU front:

LED ’Alarm MON1’ and ’ALARM MON2’ (Standby) lit.

Change ’Integrity test signal B DDM’ (TX2/ LGA2)

from 1.5 % DDM to 0.0 % DDM.

Verify shutdown of also TX2: Both TX off

Check at ECU front:

LED ’Alarm MON1’ and ’ALARM MON2’ (Exec. & Standby) lit.

LED ’Integrity Fail’ lit.

Set changed ’Integrity test signal A DDM’ (TX1) and changed ’Integ-

rity test signal B DDM’ (TX2) back to the original setting:

0.0% (A) and 1.5% (B).

Verify all reading return to normal conditions.

Perform ’Reset ECU’ to restart the system. Both TX on. Verify all reading return to normal conditions.

Equipment is serviceable. End MIT check.

6.2.5 Check of Battery Function

This check shall ensure that the battery is able to supply the installation in case of a mains interrupt.

To check the battery function perform the following procedure:

a) Both TX are on. Switch off mains supply, e.g. switch off the ACC modules. The equipment should

be supplied by the battery and runs without interruption. The LCD screen should indicate a mainte-

nance alert with ’AC1 Failure’ and ’AC2 Failure’.

b) After a few minutes (e.g. about 5 min) switch on ACC modules again. The equipment should be

supplied by the mains again and runs without interruption.

6.2.6 Documentation of System Data

The data recorded during the flight test is the only data which is binding for operation of a navigation

installation. It is advisable to check this data in accordance with the chart for periodic maintenance.

A documentation is performed by the printer of the connected PC or in a file for the transmitter data

and monitor data on the PC (.lda files).

The first data so−obtained of the basic adjustments of the alignment procedure at commissioning

and flight check should be recorded and stored in a reference file or on a floppy disk. One hardcopy

of the data should be completed with date and signature. The same procedure should be followed

when performing further checks, when the data recorded can be compared with the original flight

check data.

6.2.7 Cleaning

CAUTION

Cleaning aids, such as brushes and dusters, must be made of antistatic material. See also

the instructions in Section 6.1.2.

− Shelter

Brushes, dusters and a vacuum cleaner should be used to clean the transmitter rack and the rack

for the battery−charged power supply. The transmitter room should not be cleaned with a broom,

but rather using a vacuum cleaner.

Loading...

Loading...