114

TA117

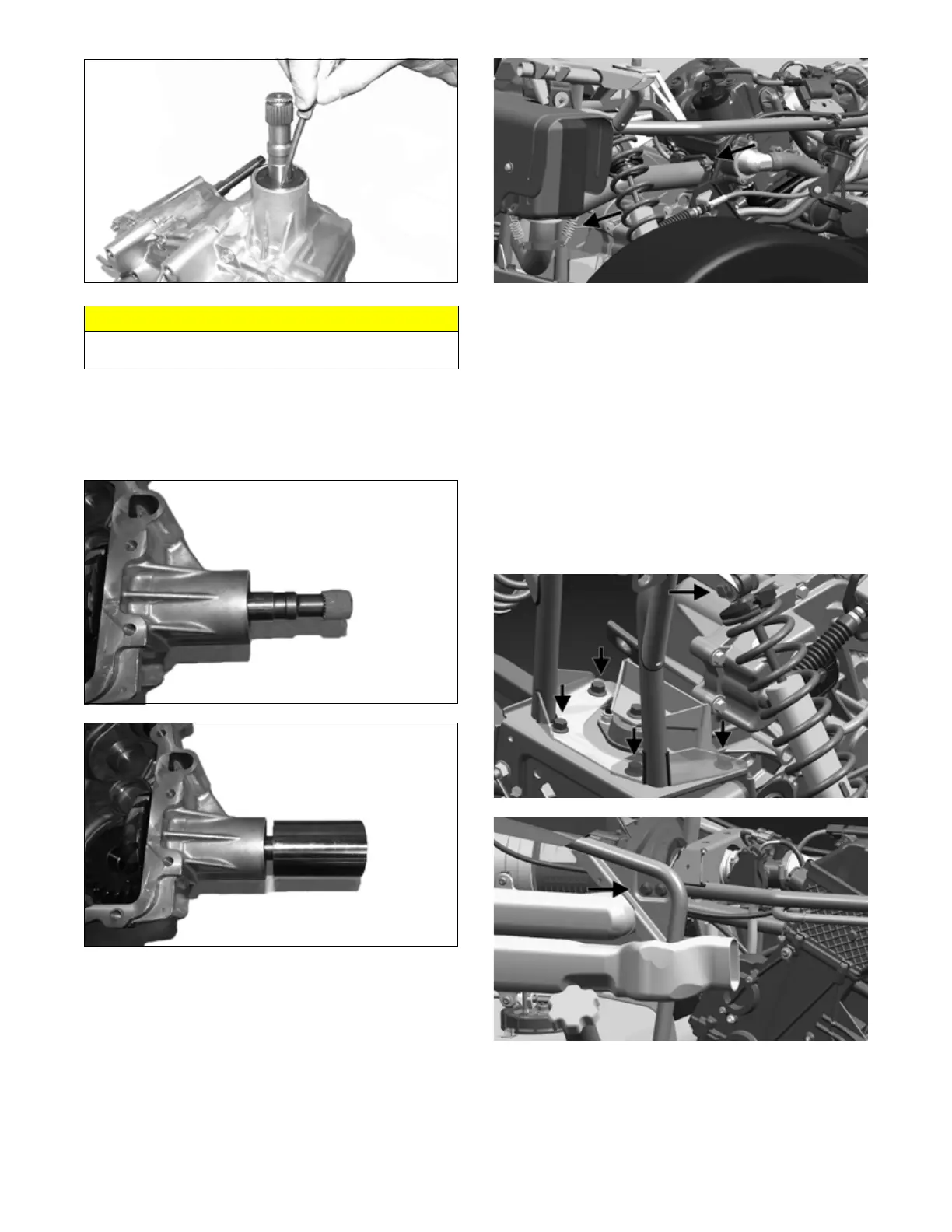

2. Wipe any oil or dirt from the seal area of the transaxle.

3. Tape the splined portion of the pinion shaft to protect

the seal; then using an appropriate seal installer,

install the front output seal (approximately 0.5-1.0

mm deep).

TA129

TA130

REMOVING TRANSAXLE

1. Remove seat, right- and left-hand side panels, rear

rack and fender, and right- and left-hand footwells

(see Steering/Body/Controls section).

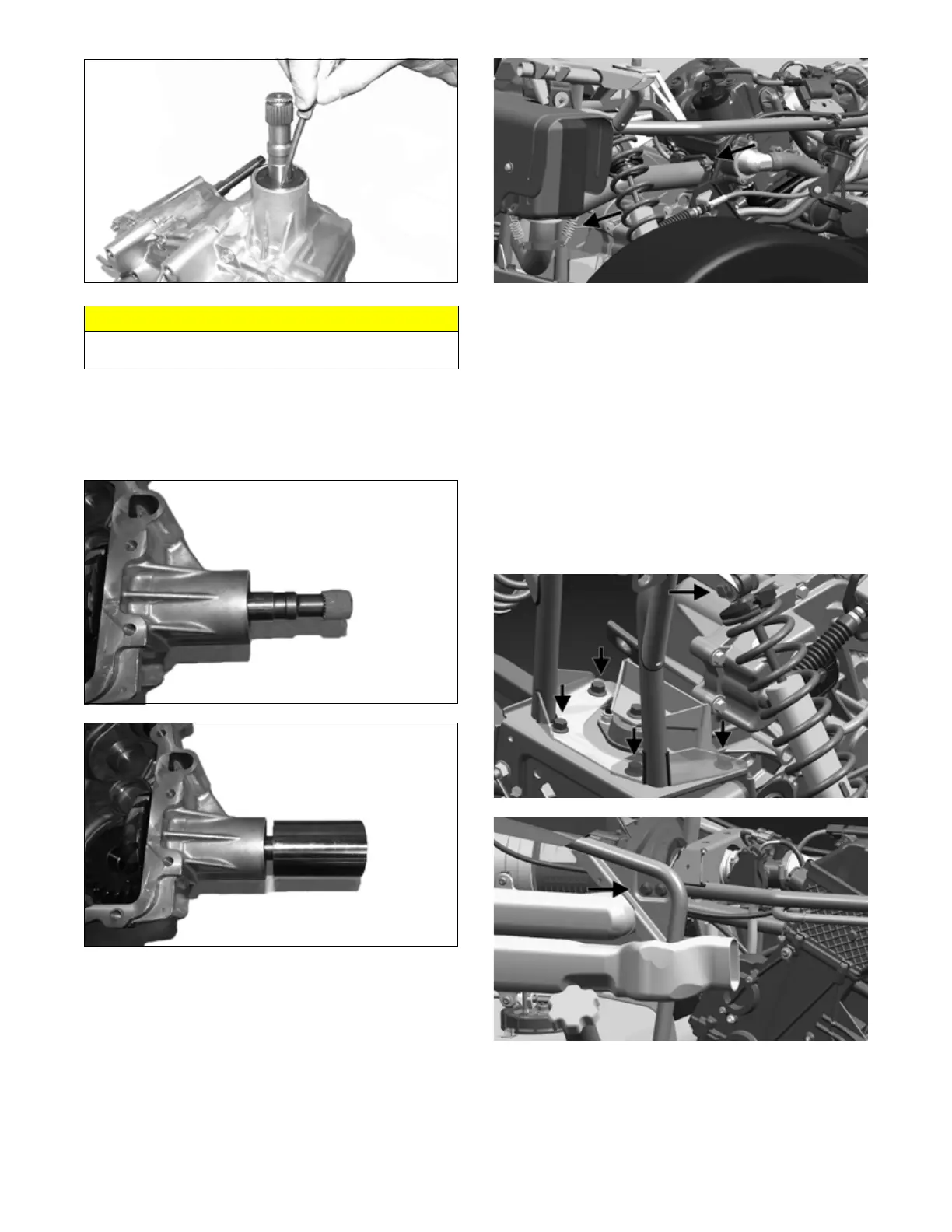

2. Disconnect the oxygen (O2) sensor. Remove exhaust

springs and nuts holding exhaust pipe to engine.

Remove pipe.

NOTE: Muffler does not need to be removed.

OHA130

3. Put vehicle on support stand and remove tires, hubs

(see Hub Assembly section) and drive axles (see

Drive Axles section).

4. Remove clutch covers, rear duct and clutch (see

Engine/Transmission section).

5. Disconnect taillight from wiring harness, remove

two push clips and cut any cable ties holding harness

to upper frame. Note locations of cable ties for

assembly. Move wiring harness out of the way.

6. To remove upper frame: Remove upper bolts holding

rear shocks to frame. Remove four cap screws hold-

ing rear upper frame to lower frame and four bolts

(two on right side, two on left side) holding front

upper frame to frame. Remove upper frame.

OHA116

OHA117

7. On left side, remove two cap screws securing tran-

saxle mounting bracket to engine.

CAUTION

Do not drive the awl too far or bearing damage will

occur.

Loading...

Loading...