42

LYC040

2. If damaged, the camshaft must be replaced.

VALVE ASSEMBLY

Removing Valves

NOTE: Index all valves, springs, and keepers to

their original position when removing. When install-

ing, all valve components should be installed in their

original position.

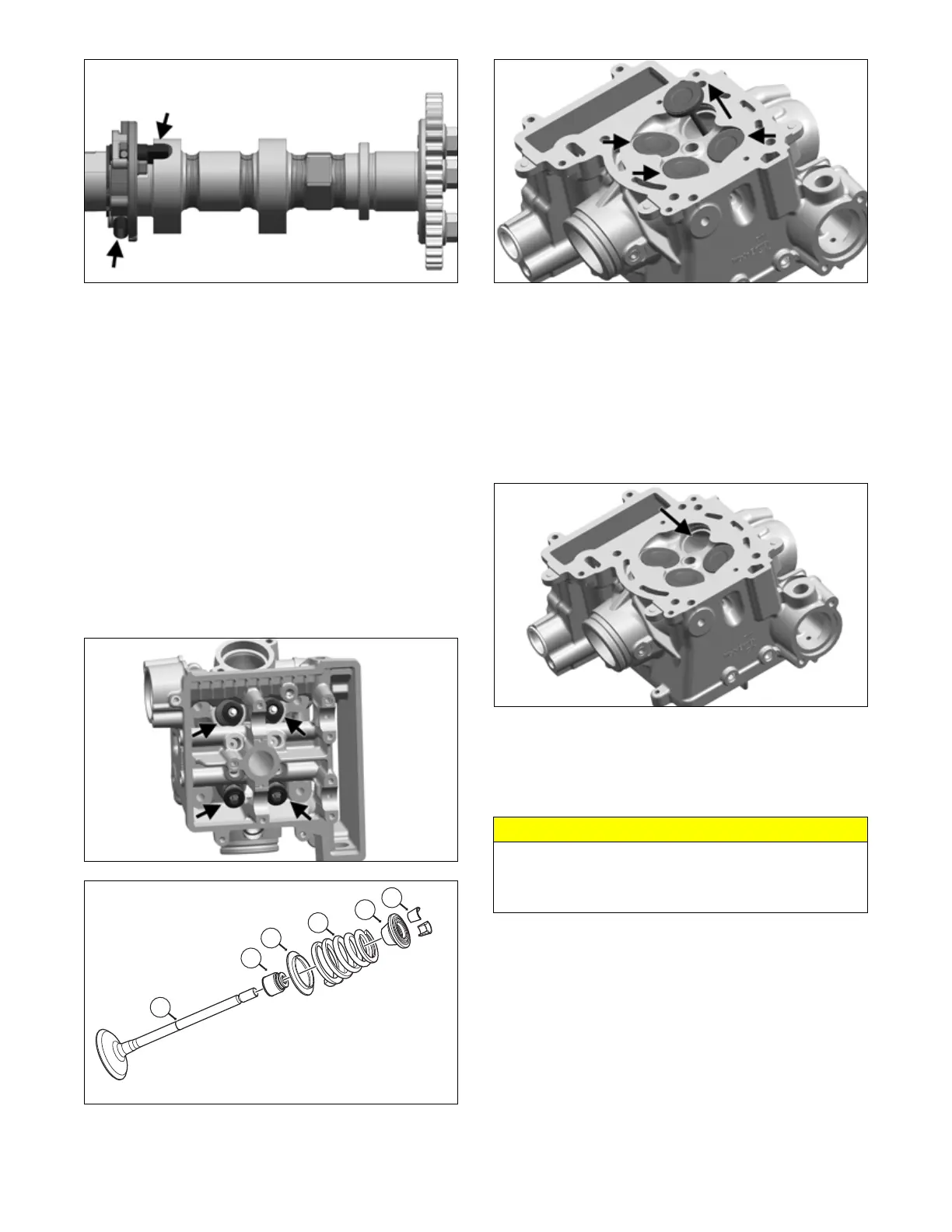

1. Using a valve spring compressor, compress the valve

spring (A) and remove the valve keepers (B).

Account for an upper spring cup (C).

2. Remove the valve seal (D) and the lower spring

retainer (E). Discard the valve seal.

NOTE: The valve seal must be replaced.

3. Remove the valve spring; then invert the cylinder

head and remove the valve (F).

LYC027

LYC028

LYC029

Measuring Valve Guide (Bore)

1. Insert a snap gauge halfway down into each valve

guide bore; then remove the gauge and measure it

with a micrometer.

2. Acceptable inside diameter range must be within

specifications.

3. If a valve guide is out of tolerance, the cylinder head

must be replaced.

Servicing Valves/Valve Guides/Valve

Seats

If valves, valve guides, or valve seats require servicing or

replacement, it is recommended that the components be

taken to a qualified machine shop for servicing.

Installing Valves

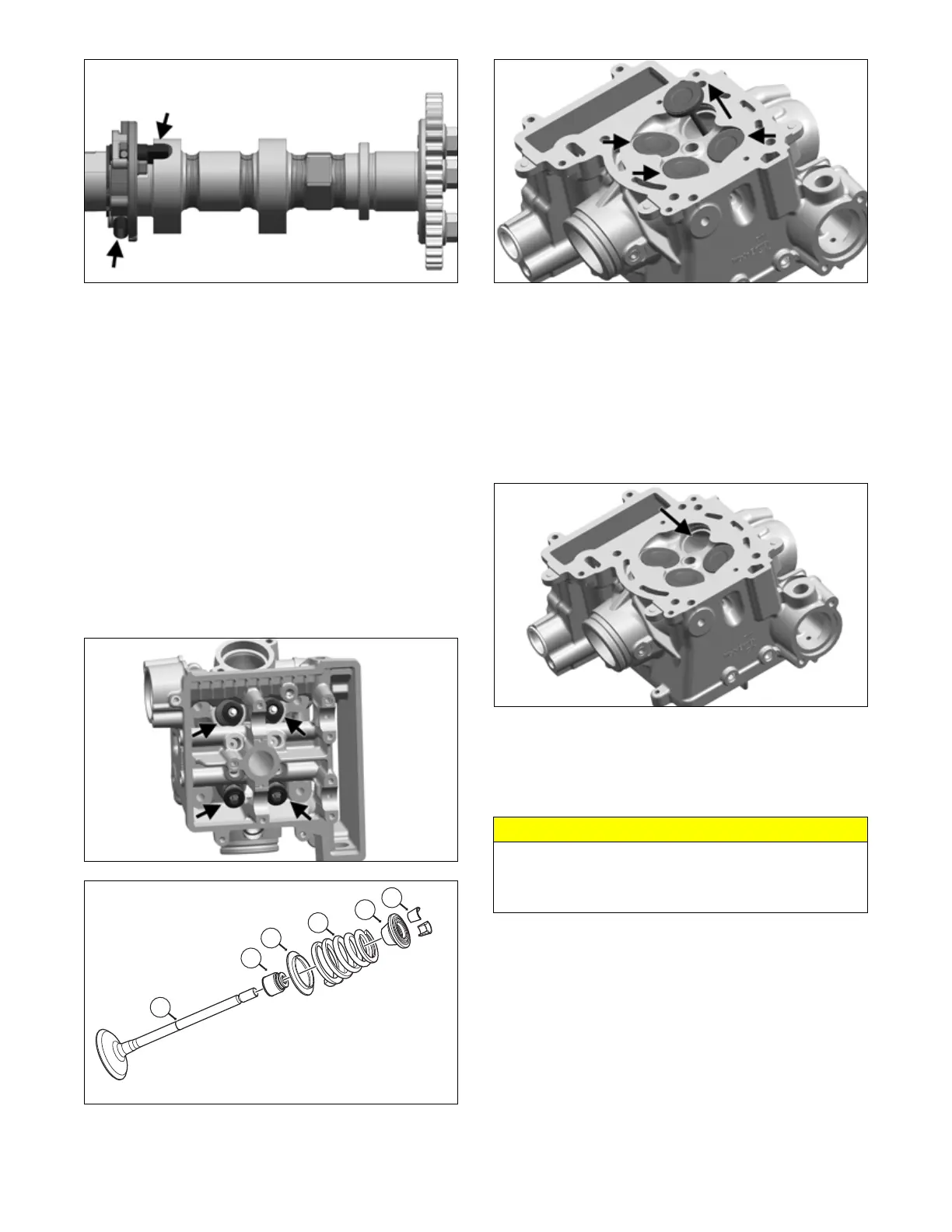

1. Insert each valve (F) into its original location on the

bottom of the cylinder head.

CAUTION

If valves are discolored or pitted or if the seating sur-

face is worn, the valve must be replaced. Do not

attempt to grind the valves or severe engine damage

may occur.

Loading...

Loading...