66

OHA145

3. Remove the cover from the movable sheave; then

remove the six mass blocks taking note of how the

mass blocks are orientated for installation purposes.

ZR-432

Cleaning and Inspecting

1. Using parts-cleaning solvent, wash grease, dirt, and

foreign matter off all components. Dry with com-

pressed air.

2. Remove any drive belt dust accumulation from the

stationary sheave, movable sheave, and bushings

using parts-cleaning solvent only.

3. Inspect stationary sheave, movable sheave, and

cover for cracks or imperfections in the casting.

4. Inspect the spring for distortion, cracks, or wear.

5. Inspect the mass blocks for damage or wear.

Assembling

1. Making sure the spring cup and washers are installed

onto the stationary sheave, install the spring.

OHA145

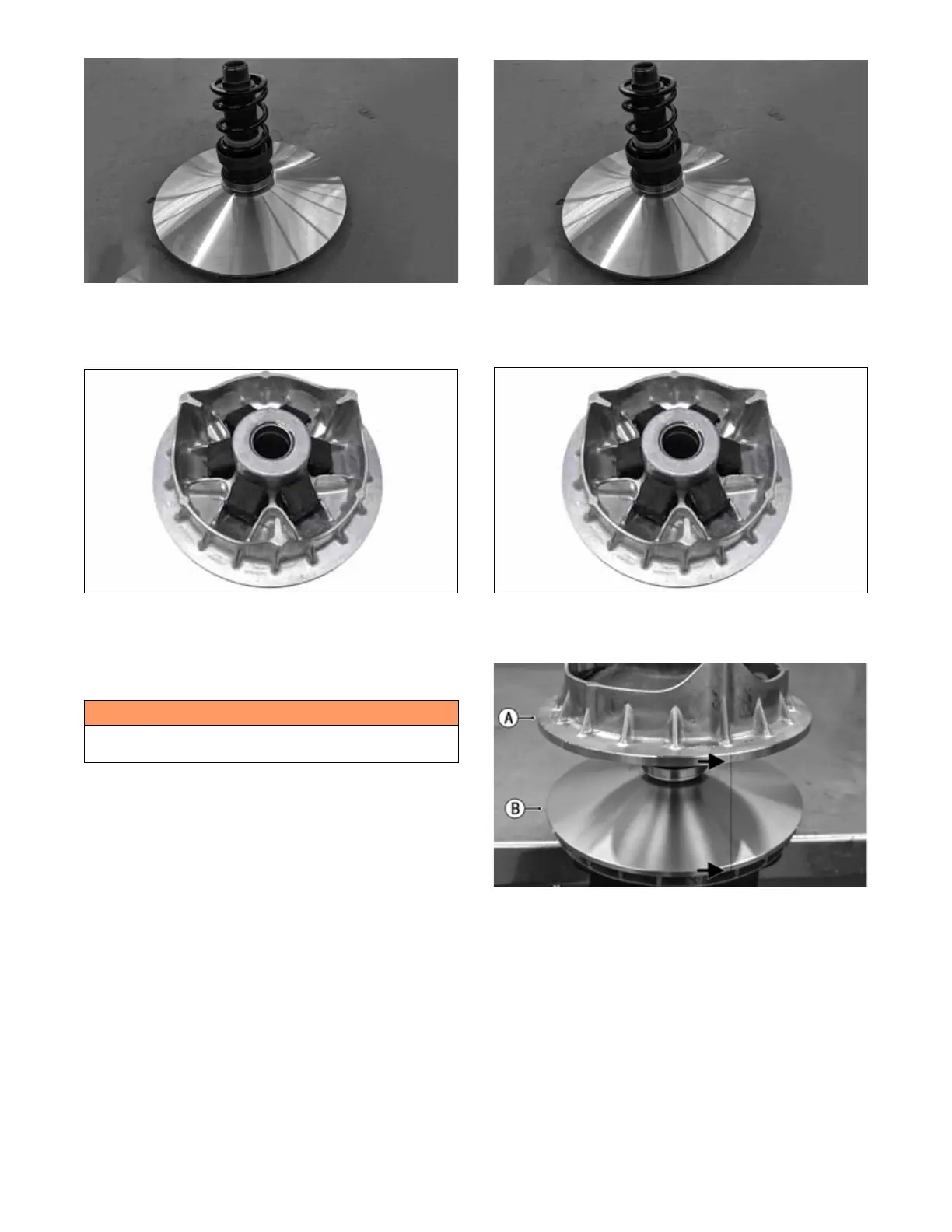

2. Install the mass blocks into the movable sheave.

NOTE: Orient blocks as shown.

ZR-432

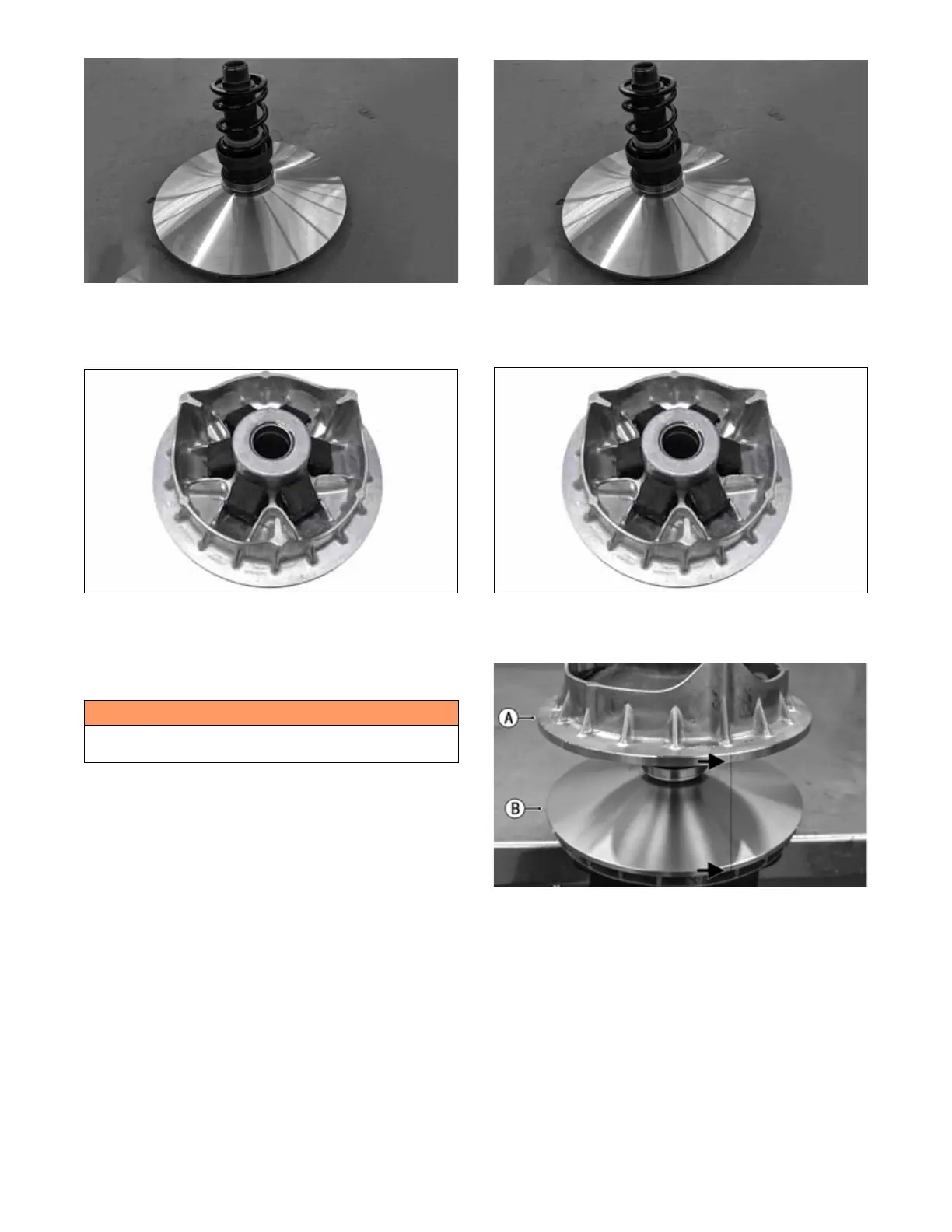

3. Install the movable sheave (A) and align with marks

on stationary sheave (B).

OHA149

4. Using a wire brush, clean the threads of the clutch

post.

5. Make sure all threads are clean and free of oily resi-

due and existing Loctite; then apply Loctite Primer T

to the threads on the stationary sheave and nut.

Allow 15 minutes for the primer to dry.

NOTE: All threads on shaft must be accessible for

tightening. Position the cover and washer on hex por-

tion of shaft with top of washer flush with bottom of

threads on shaft.

! WARNING

Always wear safety glasses when using compressed air

to dry components.

Loading...

Loading...